408-8022

Conversion Kits 690675-2 nd 692613-1

Rev

A2

of 4 Tyco Electronics Corporation

1. INTRODUCTION

These conversion kits are used to modify

AMP–O–LECTRIC Model K Terminating Machines to

accept miniature quick–change applicators. Kit No.

690675–2 is required for all end–feed and those

side–feed applicators that receive the strip terminals

in a horizontal position. Refer to the exploded view

and parts list in Figure 1 to make sure you have all

the parts required for the conversion. Kit No.

690675–2 plus Kit No. 692613–1 are required for

those side–feed applicators that receive the strip

terminals in a vertical position.

Throughout th s instructions, wh r r f r nc is

mad to hand-cycling th machin and to th

basic machin parts and ass mbli s, r f r to

Custom r Manual 409-5128.

Read the following instructions carefully before and

during the installation of the conversion kits on the

machine.

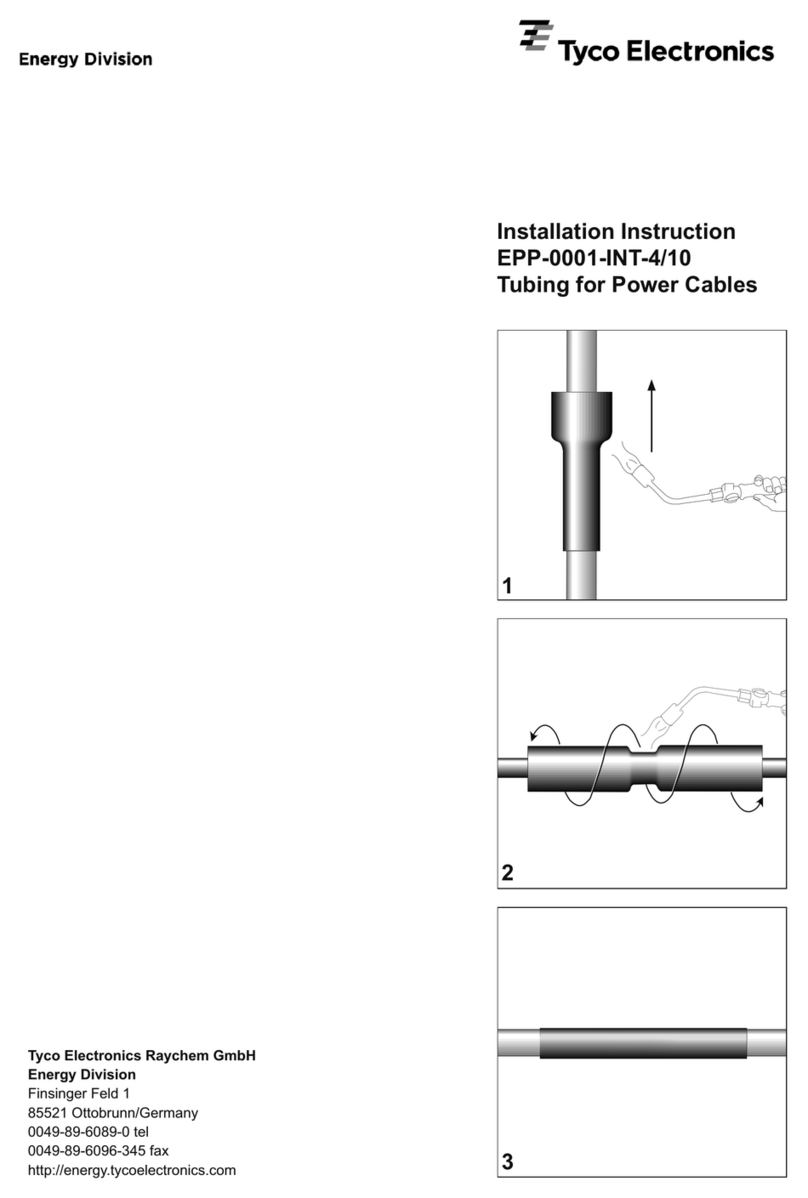

2. INSTALLATION OF CONVERSION KITS

Before starting installation of the conversion kits,

remove and store mechanical feed arm or air feed

operation arm from feed mechanism shaft by

loosening or removing clamp screws.

During installation of th conv rsion kit, c rtain

parts and ass mbli s MUST b r mov d and

ith r plac d in storag or r tain d for installation

of th kit. This kit is not r comm nd d for Mod ls

C, J, and J/K machin s.

MAKE CERTAIN that l ctrical pow r to th

machin is OFF by pulling th plug from th

r c ptacl .

2.1. Kit No. 690675-2 Inst ll tion

(Figure 2)

For installation of this kit, the machine must be

equipped with the proper vertical reel bracket

assembly (Part No. 694925–1). For information

pertaining to this assembly, refer to Customer Manual

409–5128.

1. The left–hand stock guide is required ONLY

when using side–feed applicators. With guide

installed on the bracket, attach the bracket to the

vertical reel bracket assembly with two screws

capped with knurled knobs, as shown.

2. To guide the terminal strip properly into

end–feed applicators, it is necessary that the

right–hand stock guide bracket be lowered by

using the UPPER hold in the vertical support for

the left screw, as shown.

3. Remove the two base mount screws and

washers form frame and install the base mount

supplied in the kit. Adjust height of the base mount

as low as possible in accordance with the machine

manual.

4. Hand–cycle in accordance with the machine

manual until the toggle link is at its lowest position.

5. Remove the arm retaining plate by removing the

four screws.

6. Loosen the setscrew in the ram, and then pivot

the toggle link toward the front of the machine and

slide out the toggle link pin to remove the ram.

7. Lubricate the four sides of the new ram,

supplied in the kit, as specified in the machine

manual.

8. Pivot the toggle link forward and install the new

ram with the toggle link pin removed in Step 6.

Pivot the ram back into position and tighten the

setscrew provided in the kit.

9. Install the ram retaining plate with the four

screws removed in Step 6.

10. Hand–cycle the machine to the rest position

(top dead center).

11. All parts removed for conversion, and any

unused parts of the kit, should be retained and

stored.

2.2. Kit No. 692613-1 Inst ll tion

(Figure 3)

This kit, in addition to Kit 690675–2, is required ONLY

for side feed applicators that receive strip terminals in

a vertical position.

1. Lay out the machine frame for holes as shown

in Figure 3.

2. Drill two size “G” holes, and thread with 5/16–18

UNC–2B tap.

3. Assemble the reel support as shown and install

on the machine with the two screws supplied in the

kit.

3. INSTALLATION OF THE APPLICATOR FEED CAM

it is NECESSARY for all miniature quick–change

applicators, when used in an AMP–O–LECTRIC

machine, to be equipped with the CORRECT feed

cam as listed on the applicator parts list (log) supplied

with the applicator. CHECK the feed cam, and if

necessary, replace it as described in the applicator

instructions supplied with the applicator. Retain all

parts that are removed.

NOTE

i

NOTE

i

CAUTION

!