Scope :

USER MANUAL

TNBCD Ex d Component Certified Enclosure

Date:

01.09.2022

Ver.:

3

QA Code:

5

Checked by:

E.T.

Approved by:

S.Gr.

Page:

4 of 8

Document no. :

13406

The passing on and copying of this document and the use or communication of its contents are forbidden without express authority.

Offenders are liable to payment of damages. All rights are reserved in the event of the registration of a patent .

•IEC/EN 60079-17 (Explosive atmospheres - Part 17: Electrical installations inspection

and maintenance)

•IEC/EN 60079-31 (Explosive atmospheres - Part 31: Equipment dust ignition

protection by enclosure "t")

•Decrees, orders, laws, directives, circulars, applications, standards, state of art and

other documentation relating to its installation site

It is forbidden to change anything without the prior written consent of Bartec

Technor unless the enclosure undergoes a full Equipment certification at a Notified

Body/Certifying Body.

We cannot accept any responsibility for failure to observe these regulations:

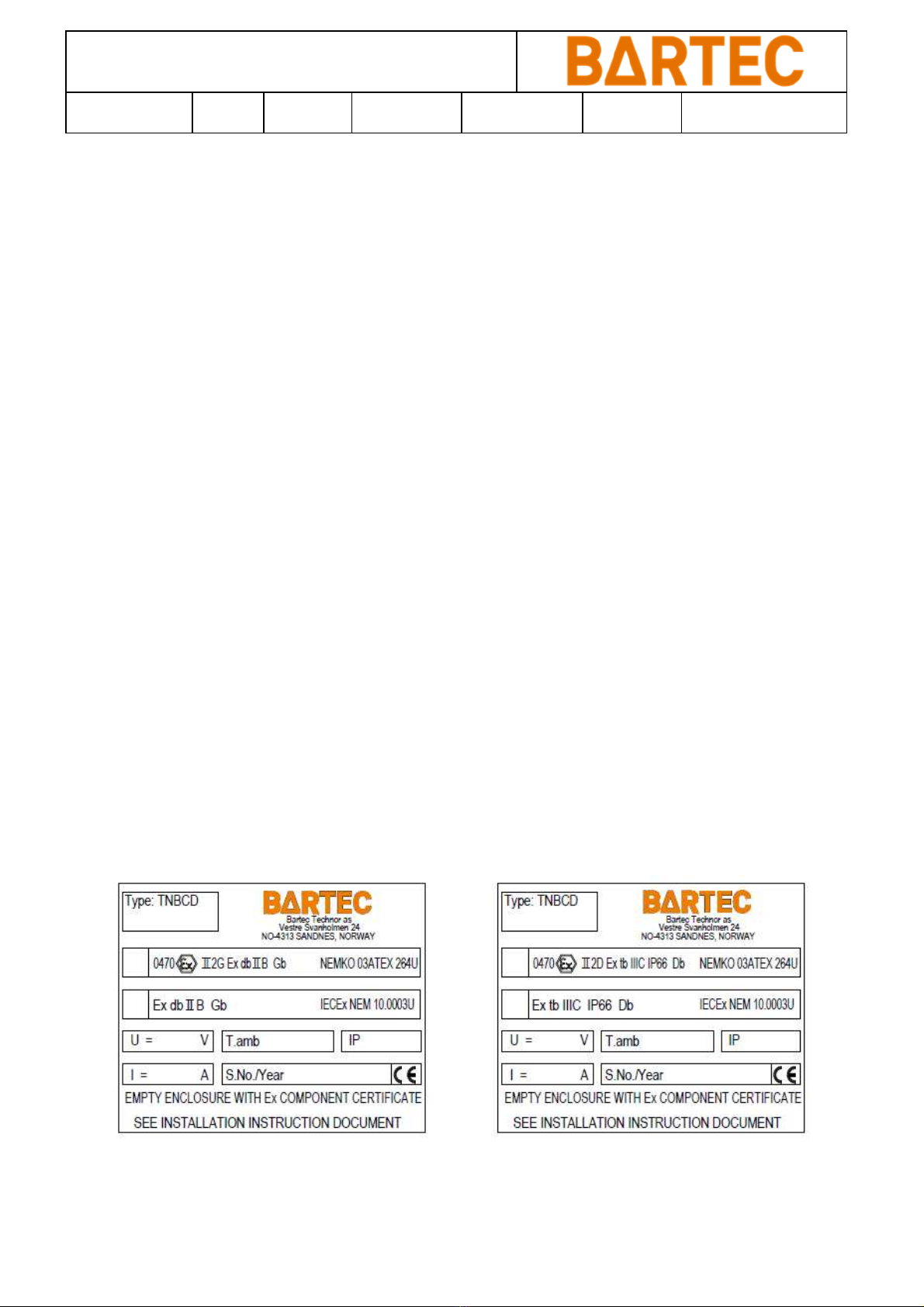

•Make sure of the compatibility between the information on the nameplate, the

explosive atmosphere present, the area of use and ambient temperatures on surfaces

•Any damage on the device can cause the explosion-proof protection to become

ineffective

•The installation of the enclosure must be done in the state of the art in the technical

domains and only by qualified, competent and empowered personnel

•A defective or abnormal use as well as the noncompliance with the instructions of the

present document exclude any clause of guarantee and do not engage our

responsibility

•The use of the device in case of excessive deposits of dusts superior at 50mm

according to EN / IEC 60079-31 is not authorized

•Liability for manufacturer traceability is ensured only at the first known delivery

destination (serial number specified on the certification label)

•It is also required to observe the regulations of the country of use

•The doors of the TNBCD enclosures are relatively heavy, to avoid sagging of the

doors, potentially making the door not align with the flange of the enclosure, the doors

shall be closed and secured during any moving and shifting of the enclosures. It is

also strongly advisable to close and secure the doors when the daily working shift is

over

•The flame paths of the doors and of the flanges of the enclosures must be well

protected whilst work is performed and ongoing inside the enclosures

Transport, storage

•Check it the product has been damaged during transport. If any damage is observed,

do the statutory reserves to the carrier

•Do not put damaged products into service

Open In a covered location, clean (without contact with

external substances) and closed with temperature a

constant humidity (-40°C < T < +70°C). Shielded from

important temperature variations

2 years and more with regular inspection (cleanliness

and mechanical damage)