C-Tech HTHY-0709 User manual

I

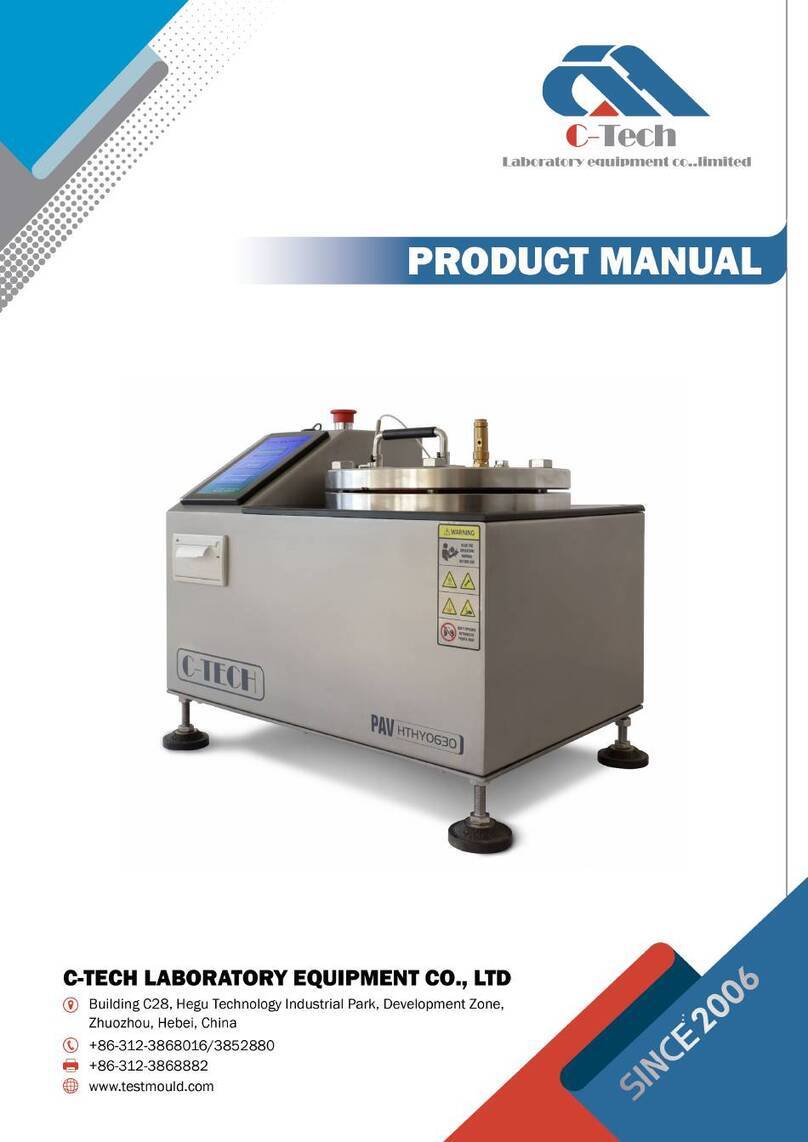

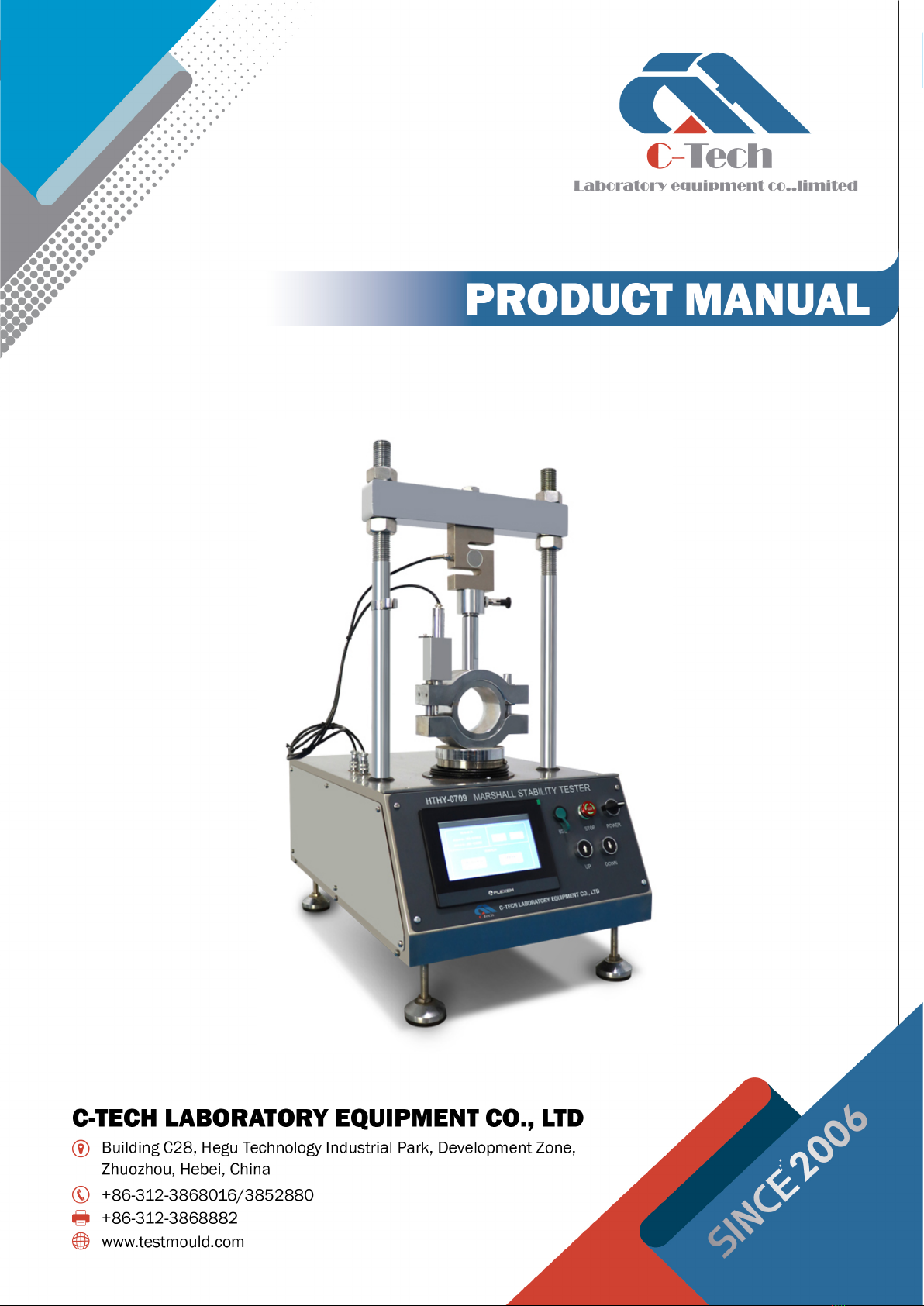

MARSHALL STABILITY TESTER HTHY-0709/0710

I

CONTENTS

I. Preface ............................................................................................................................................................1

II. Equipment Introduction ..................................................................................................................................4

III. Structure ..........................................................................................................................................................5

IV. Circuit ..............................................................................................................................................................6

V. Software ....................................................................................................................................................... 10

VI. Operation ...................................................................................................................................................... 19

VII. Maintenance and precautions .................................................................................................................... 20

VIII. Packing, storage and transportation .......................................................................................................... 20

IX. Packing list ................................................................................................................................................... 22

Appendix Description of status code and solution ............................................................................................ 23

-1 -

I. Preface

Safety tips

Notice for use

When using the equipment under different circumstances, the manufacturer does not assume any

responsibility for any foreseeable harm caused directly or indirectly to people, things or animals.

Without prior notice, the manufacturer has the right to make changes to the file information or

equipment.

The operator is responsible for all effective operations of the equipment before or during use.

Read the entire manual carefully before operating the equipment.

In order to use the equipment correctly, the operator needs to clearly understand the information

and restrictions in this manual. Only trained operators are allowed to operate the equipment.

The operator must be familiar with the operation method and structure of the equipment.

The purchaser must ensure that the operator has passed the training and is familiar with all the

information and instructions in the provided documents. Even if the above preparations are made,

the operator or user must be aware of the potential risks when operating the equipment.

Use original accessories to ensure the safety, reliability and best performance of the equipment.

Any disassembly or modification of equipment (electrical, mechanical or other) without prior written

permission from the manufacturer is considered an illegal operation, and the manufacturer declares

that it will not be liable for any damage caused thereby.

Operating requirements

This device is a dedicated device, and any other purpose is considered inapplicable. The equipment

should be used away from explosion or fire hazards.

During the operation, the condition of the equipment should be checked at any time. If it is in a

dangerous situation, stop working immediately and consult the manufacturer. It is the customer's

- 2 -

responsibility to verify whether the installation or use is carried out according to the instructions.

Please contact the manufacturer when in doubt.

Operator

WARNING!

Only qualified personnel are allowed to use, transport, install, maintain,

dismantle and dispose of the equipment; this manual is specially written for

qualified operators and contains the necessary information for using the

equipment.

"Qualified operators" refer to personnel who have received training, conducted relevant tests, are

familiar with relevant standards, restrictions and measures, and are authorized by the factory safety

manager to identify and avoid any possible hazards.

The manufacturer recommends that users strictly follow the instructions, procedures,

recommendations and effective work safety regulations in this manual, and even use appropriate

protective equipment. Be familiar with and follow the instructions, safety warnings and hazards in

this manual in order to minimize the risks of installation, operation, management and maintenance.

Table 1: Responsibilities and Obligations of Factory Safety Managers

To know the functions, instructions, safety protection

devices, and possible dangers of the equipment, all the

detailed information in this manual, can be obtained

by carefully reading this manual.

Before using this equipment, proper training and

education should be carried out for "qualified

operators". Regarding equipment protect

ion devices,

careful training must be carried out.

In order to operate the equipment, it is necessary to

understand the current safety regulations in detail, and

to carry out transportation, handling, installation, use,

maintenance and disposal by qualified operators.

Ensure that the safety device of the equipment is not

damaged or disassembled, and check it every day.

Provide operators with appropriate personal protection

tools.

The manufacturer can explain and provide assistance and training for damages caused by improper use, errors

and negligence to people or persons caused by untrained personnel, but does not assume all responsibilities.

Warning and danger signs

This equipment is designed and manufactured according to current specifications, so it is equipped

with well-designed mechanical and electrical safety devices to protect operators or users from

- 3 -

possible injury. However, during use or in certain operating procedures, the equipment still has

potential risks. Carefully read and follow the operating procedures in the manual. At the same time,

it is recommended to use personal protective tools and comply with the implementation of safety

regulations, which will reduce risks.

Attention

This symbol is used to indicate equipment damage due to non-compliance.

Warning

This symbol is used to indicate equipment damage or personal injury caused

by non-compliance.

Description

Before operation, please refer to the relevant part of the manual.

The relevant chapters of this manual contain "Warning" and "Danger" signs. These signs are

displayed in boldface with the words "Danger" or "Warning".

Dangerous area refers to an area in or near the equipment that may cause injury to people or affect

health.

The purpose of the manual

The purpose of editing this manual is to provide all the equipment operators with all necessary

installation, use and maintenance information from production to scrapping. All foreseeable

emergencies listed by the manufacturer are useful and can be verified during use.

The operator must operate the equipment by himself according to the instructions. Laboratory or site

safety managers, equipment operators and any internal and external maintenance workers must

carefully refer to this manual.

This manual is an integral part of the product. This manual must be protected and placed close to

the device for easy reference at any time.

Important note: This manual does not replace the technical training of test personnel, but must be

regarded as a guide to perform its functions. In addition, the operator should be aware of all

specifications and rules in the manual regarding the correct use of the equipment and related test

performance. The installer, laboratory or site manager is responsible for understanding this manual.

- 4 -

II. Equipment Introduction

Overview

The HTHY-0709 Marshall tester is used for the design of the mix ratio of the asphalt mixture or the

quality inspection of the asphalt pavement construction.

It can also be used to determine the mechanical properties of asphalt mixtures at specified

temperature and loading rate when splitting failure or in the elastic phase, for the design of asphalt

pavement structure to select the mechanical design parameters of asphalt mixtures and to evaluate

the low-temperature anti-cracking performance of asphalt mixtures. It can be used for Marshall

stability test and splitting test of asphalt mixture, and it can also be used for Marshall stability test

of modified asphalt.

The equipment adopts industrial touch screen control, simple operation, high automation, real-time

display of test process data, and can be connected to a thermal printer to print test results directly.

Features

1. It adopts industrial-grade color touch screen control and display, real-time display of test data

and test curves, and automatic storage of working parameters.

2. The load pressure can reach 100kN, which is far greater than the 50kN of the ordinary tester,

can meet the test requirements of unconventional special material specimens.

3. Using LVDT linear displacement sensor, the accuracy can reach 0.01mm in the full range of

(0~20) mm.

4. The self-developed software control system records the test process data throughout the whole

process (interval 20ms), and can export all the data from the USB disk for subsequent in-depth

analysis and research by scientific research users such as universities, research institutes and

so on.

5. The test speed, lifting speed and idling speed of the loading motor are steplessly adjustable,

which provides convenience for users to do scientific research experiments.

6. It can complete the outdoor road test indoors.

- 5 -

7. It has a USB communication port, which can be connected to a thermal printer to print the test

results. For special needs, the network remote communication function can be extended.

8. It has the functions of overload protection, equipment failure warning, etc., with a buzzer to alarm,

and at the same time display the fault code to show the cause of the fault.

9. The base box is made of stainless steel, which is beautiful, easy to clean and durable.

Technical specification

Maximum load

48kN / 95kN

Stability measurement range

0~48kN / 0~95kN

Stability measurement error

≤±0.1kN

Flow value measurement range

0~20mm.

Flow value measurement error

≤±0.05mm

Ascent speed of press

0~50mm/min adjustable

Communication port

Equipped with serial port output and networking port

Working voltage

AC220±10%V, 50Hz

Power consumption

1500W

Working environment temperature

0℃~60℃

Dimensions (mm)

760×510×1000 (length×width×height)

Weight

120kg

III. Structure

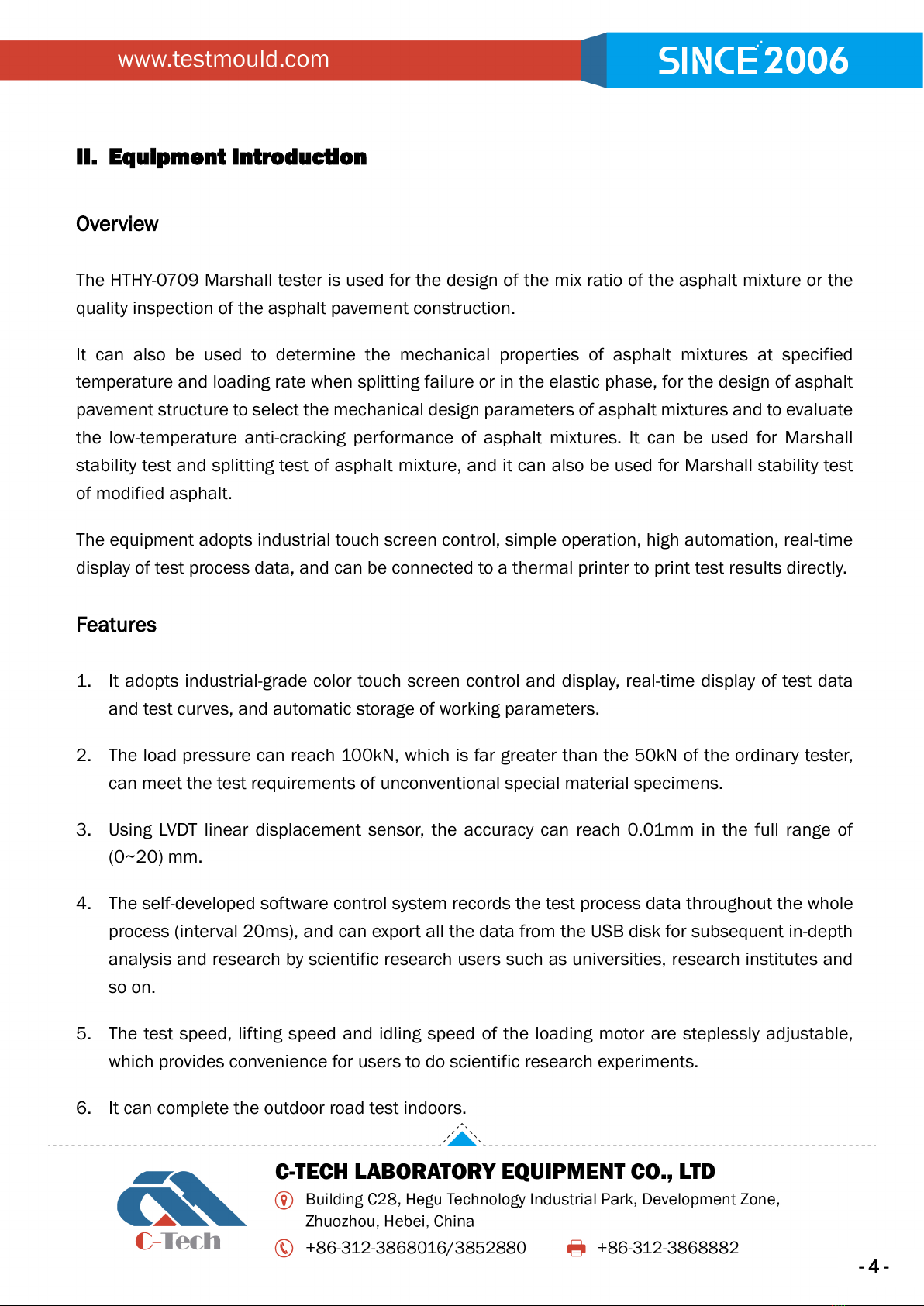

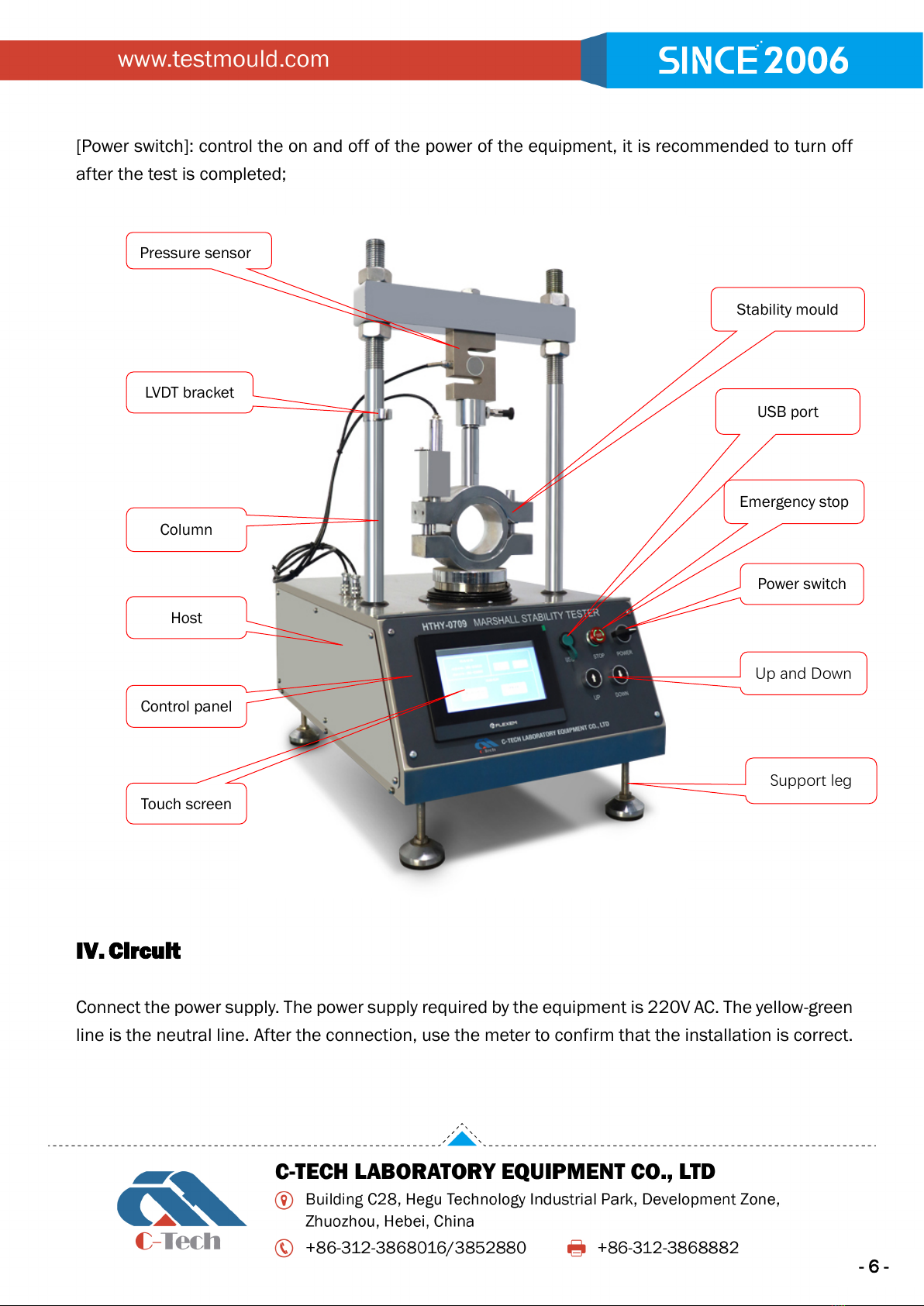

[Touch screen]: Realize human-computer interaction through the screen and perform various

operations on the device;

[UP]: Control the press to rise, after pressing the button, the press rises;

[Down]: Control the press to descend, after pressing the button, the press will descend;

[USB port]: Connect to the USB port of the touch screen, which can be used to export the data list;

[Emergency stop]: In an emergency, press the emergency stop and the press will stop;

- 6 -

[Power switch]: control the on and off of the power of the equipment, it is recommended to turn off

after the test is completed;

IV. Circuit

Connect the power supply. The power supply required by the equipment is 220V AC. The yellow-green

line is the neutral line. After the connection, use the meter to confirm that the installation is correct.

Pressure sensor

LVDT bracket

Column

Host

Control panel

Stability mould

Touch screen

Support leg

USB port

Emergency stop

Power switch

Up and Down

- 7 -

WARNING!

The equipment shell must be reliably grounded, and it is strictly forbidden to

turn on the equipment before the equipment shell is reliably grounded!

Figure 4-1 Circuit part

- 8 -

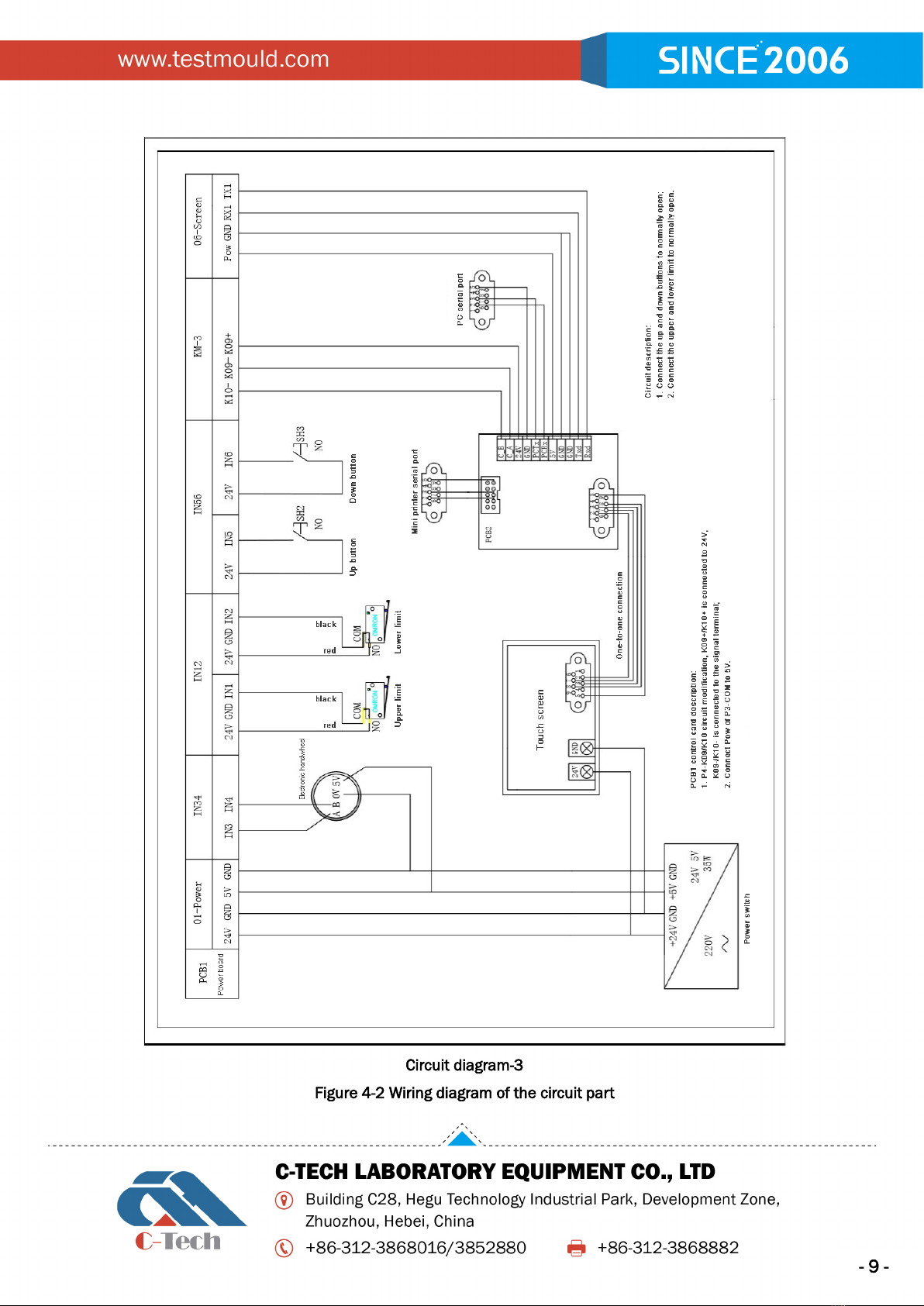

Diagram 1

Diagram 2

- 9 -

Circuit diagram-3

Figure 4-2 Wiring diagram of the circuit part

- 10 -

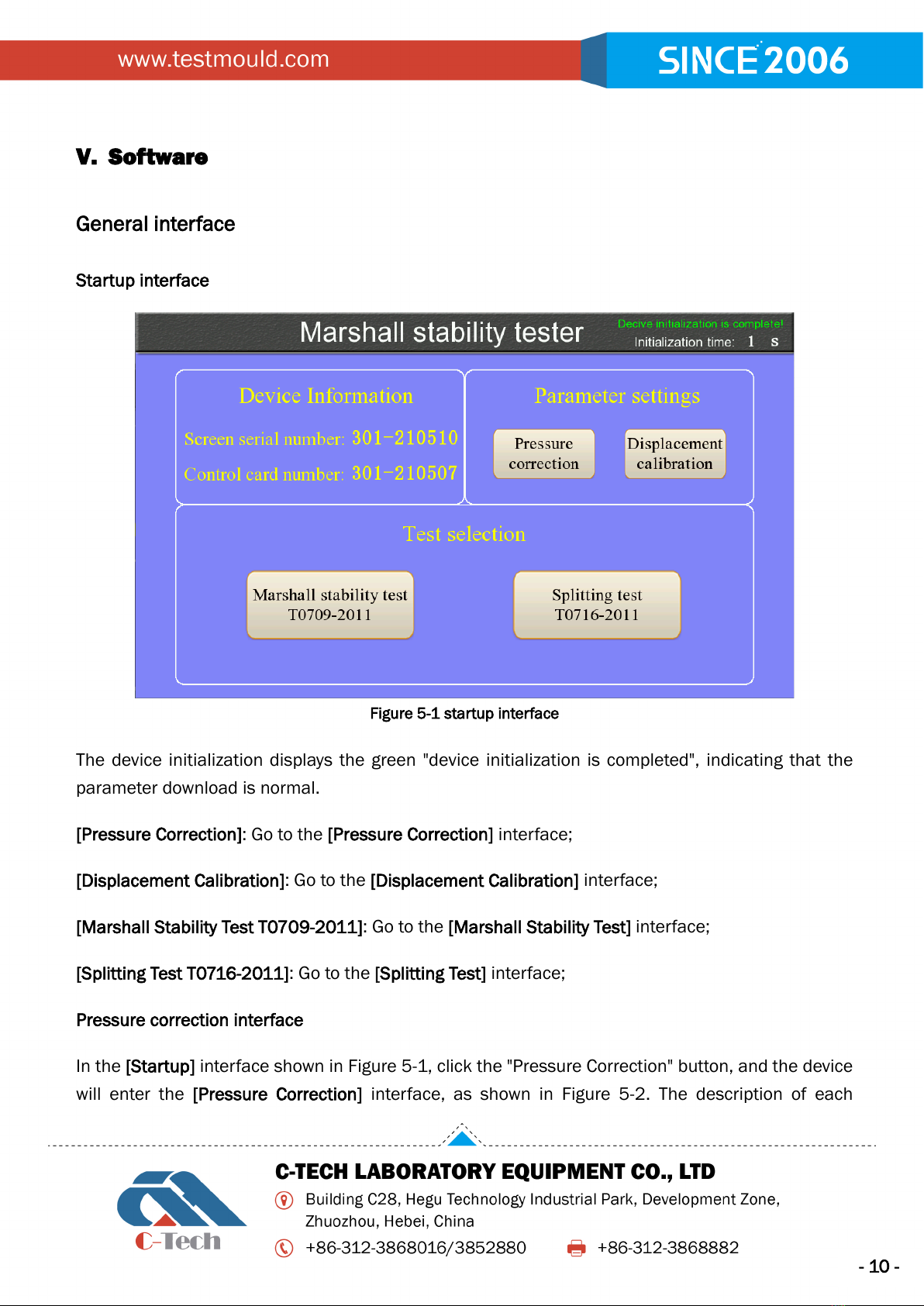

V. Software

General interface

Startup interface

Figure 5-1 startup interface

The device initialization displays the green "device initialization is completed", indicating that the

parameter download is normal.

[Pressure Correction]: Go to the [Pressure Correction] interface;

[Displacement Calibration]: Go to the [Displacement Calibration] interface;

[Marshall Stability Test T0709-2011]: Go to the [Marshall Stability Test] interface;

[Splitting Test T0716-2011]: Go to the [Splitting Test] interface;

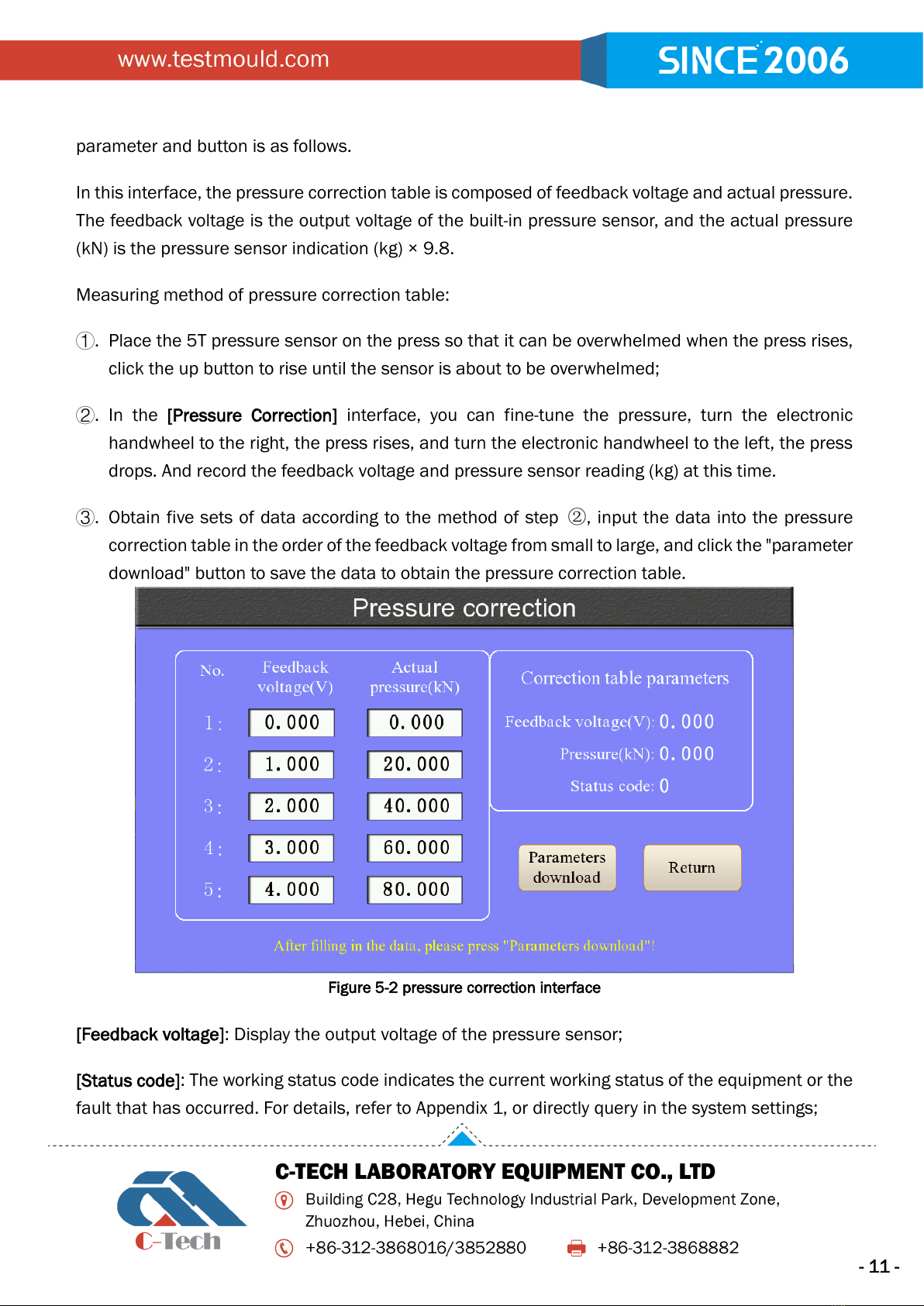

Pressure correction interface

In the [Startup] interface shown in Figure 5-1, click the "Pressure Correction" button, and the device

will enter the [Pressure Correction] interface, as shown in Figure 5-2. The description of each

- 11 -

parameter and button is as follows.

In this interface, the pressure correction table is composed of feedback voltage and actual pressure.

The feedback voltage is the output voltage of the built-in pressure sensor, and the actual pressure

(kN) is the pressure sensor indication (kg) × 9.8.

Measuring method of pressure correction table:

①.Place the 5T pressure sensor on the press so that it can be overwhelmed when the press rises,

click the up button to rise until the sensor is about to be overwhelmed;

②.In the [Pressure Correction] interface, you can fine-tune the pressure, turn the electronic

handwheel to the right, the press rises, and turn the electronic handwheel to the left, the press

drops. And record the feedback voltage and pressure sensor reading (kg) at this time.

③.Obtain five sets of data according to the method of step ②, input the data into the pressure

correction table in the order of the feedback voltage from small to large, and click the "parameter

download" button to save the data to obtain the pressure correction table.

Figure 5-2 pressure correction interface

[Feedback voltage]: Display the output voltage of the pressure sensor;

[Status code]: The working status code indicates the current working status of the equipment or the

fault that has occurred. For details, refer to Appendix 1, or directly query in the system settings;

- 12 -

[Parameter download]: Click this button to transfer the set parameters to the control card. After

changing the parameters, you must perform this operation to make the parameters take effect;

[Return]: Click this button to return to the [Startup] interface.

WARNING!

1. This interface is mainly used for maintenance and testing by engineers,

and does not require users to master it.

2. The user is not allowed to enter and modify the parameters at will,

otherwise the pressure will be inaccurate, which will affect the accuracy of

the test results!

Displacement calibration interface

In the [Startup] interface shown in Figure 5-1, click the "Displacement Calibration" button, and the

device will enter the [Displacement Calibration] interface, as shown in Figure 5-3. The description of

each parameter and button is as follows.

Figure 5-3 displacement calibration interface

[Voltage]: The output voltage of the displacement sensor;

[Displacement]: The current displacement of the displacement sensor;

- 13 -

[Status Code]: The working status code indicates the current working status of the device or the fault

that has occurred. For details, refer to Appendix 1, or directly query in the system settings;

[Parameter download]: Click this button to transfer the set parameters to the control card. After

changing the parameters, you must perform this operation to make the parameters take effect;

[Return]: Click this button to return to the [Startup] interface.

WARNING!

1. This interface is mainly used for maintenance and testing by engineers,

and does not require users to master it.

2. The user is not allowed to enter and modify the parameters at will,

otherwise the displacement will be inaccurate, which will affect the accuracy

of the test results!

Marshall Stability Test interface

In the [Startup] interface shown in Figure 5-1, click the "Marshall Stability Test" button, the device

enters the [Marshall Stability Test] interface; click the "Splitting Test" button, the device enters the

[Splitting Test] interface;

Since the functions and settings are roughly the same in each test, they both include two parts:

[System Settings] and [Data Processing]. The difference is the test process, test calculation method

and test results. So take the Marshall stability test as an example to explain the operation method

of the instrument software.

[Marshall Stability Test]interface is shown in Figure 5-4. In this interface, the upper right side is the

"load-deformation curve" of the test, the lower right side is the test result, and the left side is the test

function buttons and setting buttons. The description of each parameter and button is as follows.

[Start test]: After clicking this button, the font turns red, and the Marshall stability test starts;

[System Settings]: After clicking this button, enter the "System Settings" interface;

[Save]: After clicking this button, enter the "Data Processing" interface;

[Print]: Click this button to start printing.

- 14 -

Figure 5-4 Marshall stability test interface

System settings

In the [Test] interface shown in Figure 5-4, click the "System Settings" button to enter [System

Settings]. "System Settings" includes "Parameter Settings", "Parameter Save", "Signal Test", "Status

Code Description" and other interfaces.

Click the green or red button at the top of the interface to select the operation to be performed:

(1) Click the "Save Parameters" button to enter the [Save Parameters]interface to save and restore

parameters;

(2) Click the "Signal Testing" button to enter the [Signal Testing] interface, which is used for engineers

to debug and can view various parameters and instrument tests;

(3) Click the "Parameter Settings" button to enter the [Parameter Settings] interface to set various

parameters;

(4) Click the "Status Code Description" button to enter the [Status Code Description] interface to view

the equipment fault code and troubleshooting methods;

- 15 -

(5) Click the "Exit" button to exit the "System Settings" and return to the "Test" interface.

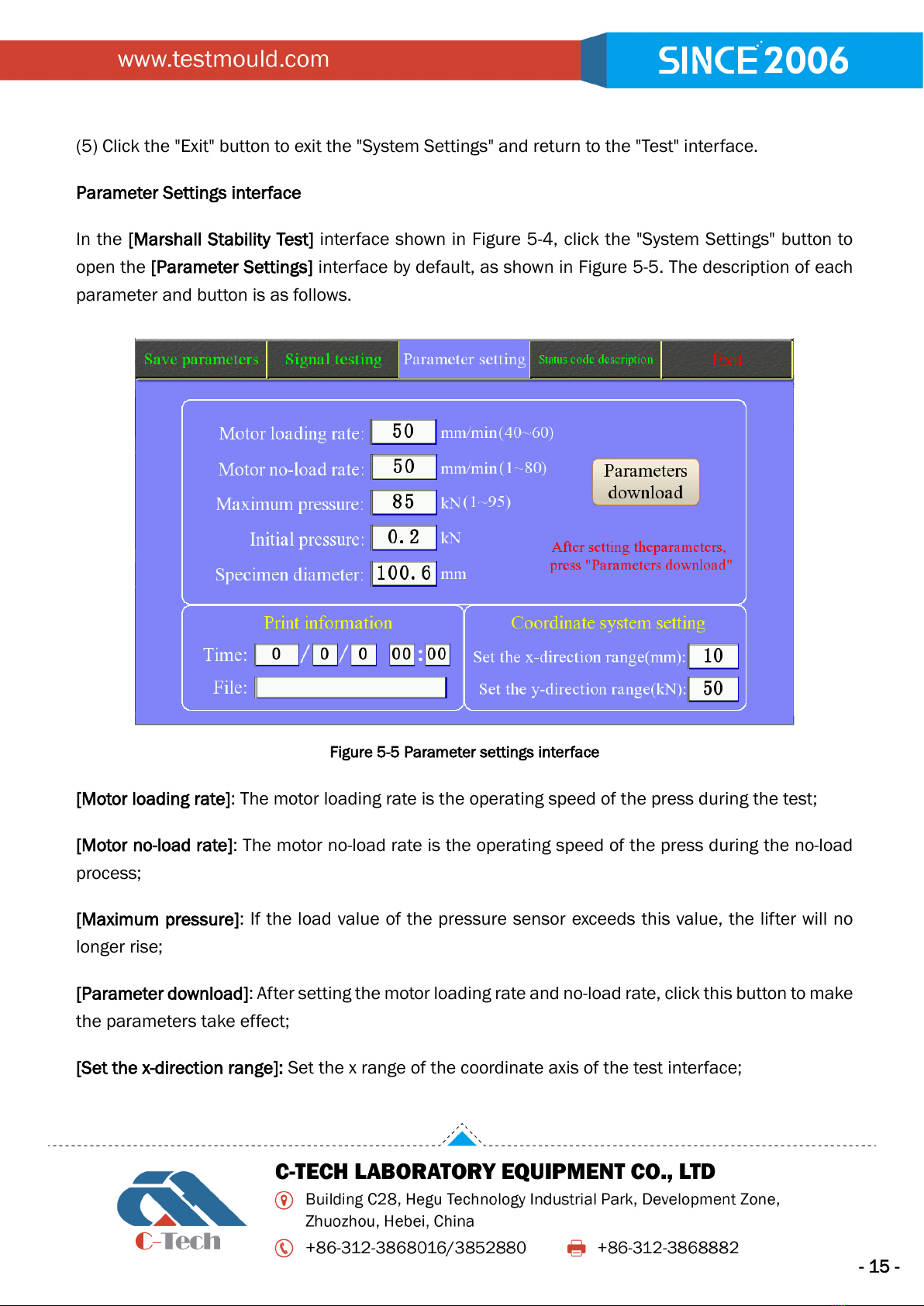

Parameter Settings interface

In the [Marshall Stability Test] interface shown in Figure 5-4, click the "System Settings" button to

open the [Parameter Settings] interface by default, as shown in Figure 5-5. The description of each

parameter and button is as follows.

Figure 5-5 Parameter settings interface

[Motor loading rate]: The motor loading rate is the operating speed of the press during the test;

[Motor no-load rate]: The motor no-load rate is the operating speed of the press during the no-load

process;

[Maximum pressure]: If the load value of the pressure sensor exceeds this value, the lifter will no

longer rise;

[Parameter download]: After setting the motor loading rate and no-load rate, click this button to make

the parameters take effect;

[Set the x-direction range]: Set the x range of the coordinate axis of the test interface;

- 16 -

[Set the y-direction range]: Set the y range of the coordinate axis of the test interface.

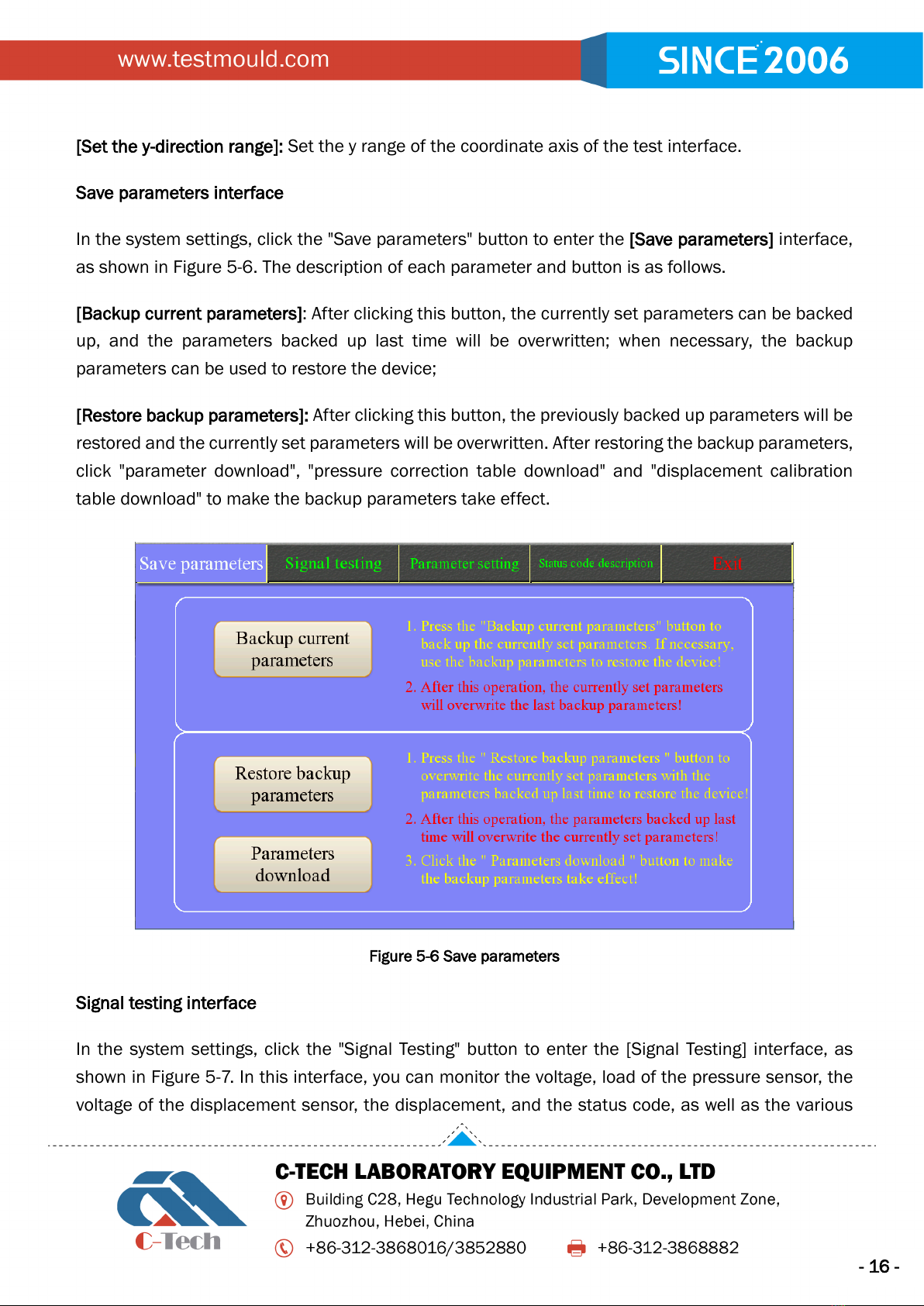

Save parameters interface

In the system settings, click the "Save parameters" button to enter the [Save parameters] interface,

as shown in Figure 5-6. The description of each parameter and button is as follows.

[Backup current parameters]: After clicking this button, the currently set parameters can be backed

up, and the parameters backed up last time will be overwritten; when necessary, the backup

parameters can be used to restore the device;

[Restore backup parameters]: After clicking this button, the previously backed up parameters will be

restored and the currently set parameters will be overwritten. After restoring the backup parameters,

click "parameter download", "pressure correction table download" and "displacement calibration

table download" to make the backup parameters take effect.

Figure 5-6 Save parameters

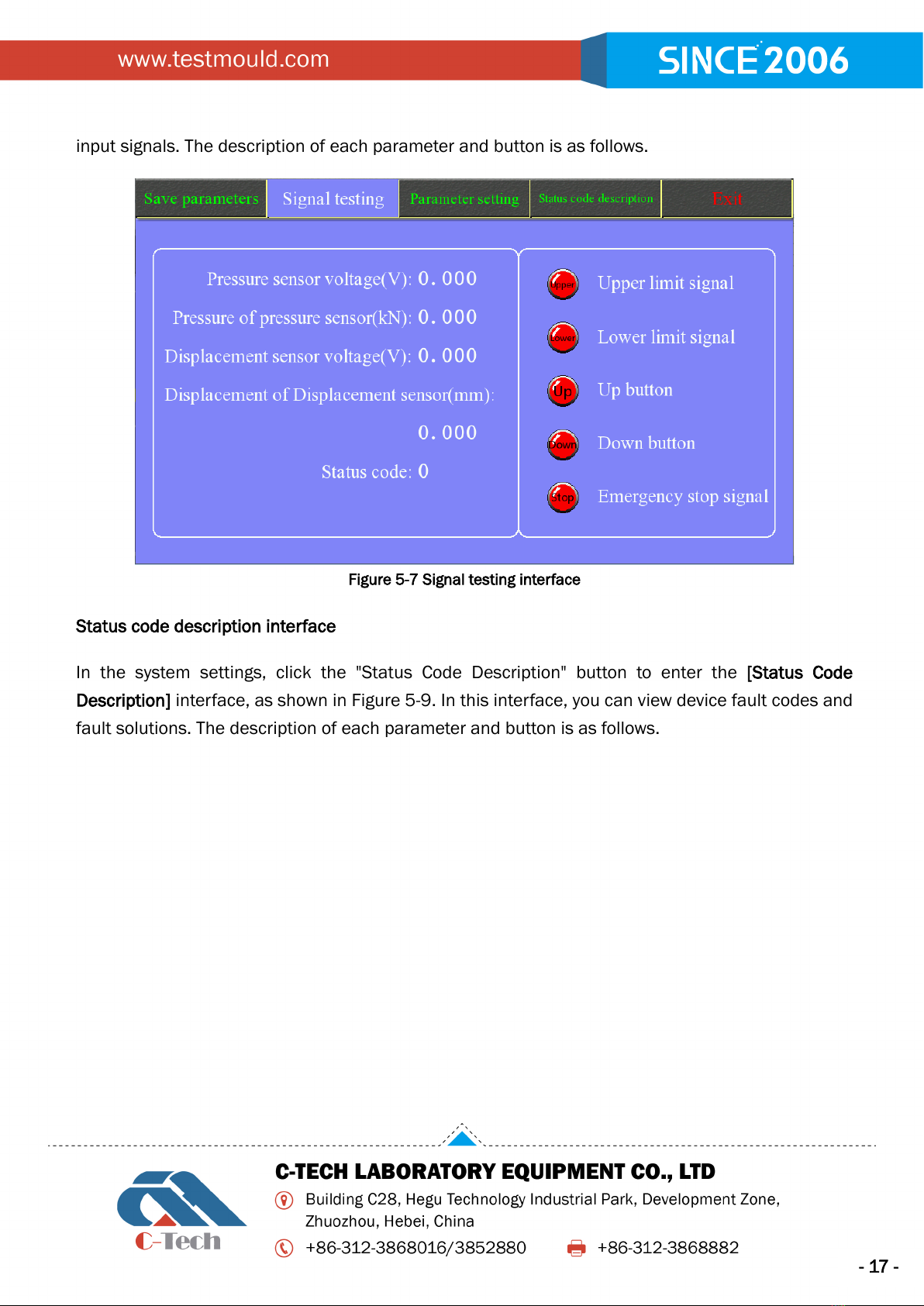

Signal testing interface

In the system settings, click the "Signal Testing" button to enter the [Signal Testing] interface, as

shown in Figure 5-7. In this interface, you can monitor the voltage, load of the pressure sensor, the

voltage of the displacement sensor, the displacement, and the status code, as well as the various

- 17 -

input signals. The description of each parameter and button is as follows.

Figure 5-7 Signal testing interface

Status code description interface

In the system settings, click the "Status Code Description" button to enter the [Status Code

Description] interface, as shown in Figure 5-9. In this interface, you can view device fault codes and

fault solutions. The description of each parameter and button is as follows.

- 18 -

Figure 5-9 Status code description interface

Data processing

The description of each parameter and button is as follows.

[Status remainder]: Indicates the status and progress of data opening or saving;

[File name]: Set the file name of the storage content;

[File Path]: Display the location of the saved or opened file.

[Open]: Click this button, select the location of the saved file, and open it, and check whether the

data has been opened according to the status reminder;

[Save]: Click this button to save the test data to the selected location, and check whether the storage

is complete according to the status reminder;

This manual suits for next models

1

Table of contents

Other C-Tech Test Equipment manuals