C-Tech HTHY-0630 PAV User manual

I

ASPHALT PRESSURE AGING VESSEL HTHY-0630 PAV

I

CONTENTS

I. Preface ............................................................................................................................................................1

II. About HTHY-0630 PAV ...................................................................................................................................4

III. Structure ..........................................................................................................................................................6

IV. Hardware .........................................................................................................................................................8

V. Device connection ..........................................................................................................................................8

VI. Software ..........................................................................................................................................................9

VII. Calibration .................................................................................................................................................... 14

VIII. Operation ...................................................................................................................................................... 14

IX. Maintenance ................................................................................................................................................ 15

-1 -

I. Preface

Safety tips

Notice for use

When using the equipment under different circumstances, the manufacturer does not assume any

responsibility for any foreseeable harm caused directly or indirectly to people, things or animals.

Without prior notice, the manufacturer has the right to make changes to the file information or

equipment.

The operator is responsible for all effective operations of the equipment before or during use.

Read the entire manual carefully before operating the equipment.

In order to use the equipment correctly, the operator needs to clearly understand the information

and restrictions in this manual.

Only trained operators are allowed to operate the equipment.

The operator must be familiar with the operation method and structure of the equipment.

The purchaser must ensure that the operator has passed the training and is familiar with all the

information and instructions in the provided documents. Even if the above preparations are made,

the operator or user must be aware of the potential risks when operating the equipment.

Use original accessories to ensure the safety, reliability and best performance of the equipment.

Any disassembly or modification of equipment (electrical, mechanical or other) without prior written

permission from the manufacturer is considered an illegal operation, and the manufacturer declares

that it will not be liable for any damage caused thereby.

Operating requirements

This equipment is a special equipment, any other purpose is considered unsuitable, the equipment

should be used away from explosion or fire hazards.

During operation, check the condition of the equipment. If it is in a dangerous situation, stop working

- 2 -

immediately and consult the manufacturer's after-sales service department. It is the customer's

responsibility to verify whether the installation or use is carried out according to the instructions.

Please contact the manufacturer when in doubt.

Operator

WARNING!

Only qualified personnel are allowed to use, transport, install, maintain, dismantle

and dispose of the equipment. This manual is specially written for qualified

operators and contains the necessary information for using the equipment.

"Qualified Operator" means a person who has been trained, has done relevant tests, is familiar with

relevant standards, restrictions and measures, is authorized by the factory safety manager, can

perform any necessary activities, and can identify and avoid any possible hazards.

The manufacturer recommends strictly abide by the instructions, procedures, recommendations and

effective work safety regulations in this manual, and even use appropriate protective equipment

(whether it is a person or a part of a machine).

Be familiar with and follow the instructions, safety warnings and dangers in this manual in order to

minimize the risks of installation, operation, management and maintenance.

Responsibilities and obligations of factory safety managers

Know the functions of this equipment, its instructions, safety protection devices, possible hazards during use,

and all the detailed information in this manual, you can obtain knowledge of these aspects by carefully reading

this manual.

Before using this equipment, properly train and educate "qualified operators", and carefully train these

personnel with regard to the protective device of the machine.

In order to operate the equipment, it is necessary to understand the current safety regulations in detail, and

arrange qualified operators for transportation, handling, installation, use, maintenance and disposal, etc.

Ensure that the safety device of the equipment is not damaged or disassembled, and check it every day.

Provide operators with appropriate personal protective equipment.

The manufacturer can explain, provide assistance and training for untrained personnel who cause damage to

things or people due to improper use, error and negligence, but does not assume all responsibilities.

-3 -

Warning and danger signs

This equipment is designed and manufactured in accordance with the current standards, so it is

equipped with well-designed mechanical and electrical safety devices to protect the operator or user

from possible injury. However, during use or in certain operating procedures, the equipment still has

potential risks. Carefully read and follow the operating procedures in the manual. At the same time,

it is recommended to use personal protective equipment and comply with the implementation of

safety regulations, which will reduce risks.

The relevant chapters of this manual contain "WARNING" and “DANGER” signs. These signs are

displayed in bold type "WARNING" and “DANGER”.

WARNING!

This symbol is used to indicate that non-compliance may damage the equipment.

DANGER!

This symbol is used to indicate a situation where non-compliance will damage the equipment or injure

people.

DESCRIPTION

Before proceeding, please refer to the relevant part of the manual.

Dangerous area refers to the area in or near the equipment that may cause injury to people or affect

health.

Purpose of writing the operation manual

The purpose of editing this manual is to provide all operators of the equipment with all necessary

installation, use and maintenance information from production to scrapping in a comprehensive and

clear manner, which is useful for all foreseeable emergencies listed by the manufacturer.

The operator must operate the equipment by himself according to the instructions. Laboratory or site

safety managers, equipment operators and any internal and external maintenance workers must

read this manual carefully.

The manual is an integral part of the product and is related to the equipment.

This manual must be protected and placed close to the equipment for easy reference at any time.

-4 -

IMPORTANT NOTE: This manual does not replace testing and technical training of workers, but it must

be seen as a guide to perform its functions. In addition, the operator should be aware of all standards

and rules in the manual regarding the correct use of the equipment and related test performance. It

is the responsibility of the installer, laboratory or site manager to understand this manual. The

manufacturer can provide further information.

II. About HTHY-0630 PAV

Description

ASPHALT PRESSURE AGING VESSEL HTHY-0630 PAV uses high temperature and high pressure to

accelerate the aging rate of asphalt binder, thereby simulating the oxidation aging of asphalt binder

during use, and is used to evaluate the oxidation resistance of different asphalt under certain test

temperature and pressure conditions.

Features

7-inch high-definition display controller, real-time monitoring of pressure and temperature in the

chamber;

Display the temperature-time and pressure-time curves in the chamber during the working

process;

Real-time display of the temperature error time and pressure error time of the aging process (to

meet the requirements of the new specification);

Temperature and pressure linkage control to ensure no overheating during pressurization;

Record the data once every 5s, and export it as excel format data via U disk;

After the test is completed, the process data can be automatically printed;

Safety protection designs such as over-temperature, over-pressure protection, and high-pressure

relief can effectively protect experimenters working under high-temperature and high-pressure

experimental conditions;

With overload protection, fault warning and other functions, there is a buzzer sound alarm

-5 -

prompt and display the fault code at the same time;

The cabinet is made of stainless steel, treated with special technology, beautiful and generous,

easy to clean and durable.

Technical specifications

Working

temperature range

90~110℃

Temperature control

accuracy

Resolution 0.1℃, accuracy ±0.5℃

Preheating time

40min~60min

Temperature-

pressure

Real-

time display temperature and

pressure values and curve relationship

Working pressure

2.1MPa±0.1MPa

Actual pressure

control accuracy

±0.02MPa

Pressure sensor

0-3MPa

Accuracy

0.5% (±0.015 MPa)

Air supply

Cylinder compressed

air, air pressure

greater than 3MPa

Air supply connector

Equipped with high-

pressure pressure

reducing valve and converted high-

pressure air pipe matching with industrial

compressed air bottles as standard

Safety relief

Greater than 2.5Mpa

Safety valve

When the pressure in the chamber

exceeds 2.5Mpa, the safety valve

automatically releases pressure

Power supply

AC220V 50Hz

Dimensions

550X350X450 mm

Power

1.5kw

Weight

60kg

Accessories

1 high-pressure pressure reducing

valve, 1 high-pressure resistant air

inlet pipe (3m), used to connect the

equipment to the compressed air

bottle, and adjust the inlet pressure

of the air source

Sample dishes (10 pcs) and rack

-6 -

Storage, transport and moving

Storage

WARNING!

The device must be stored in its original packaging in a closed environment. The minimum temperature

for protection from atmospheric damage is -15C°, the maximum is 60°C, and the maximum humidity

is 70%.

Transport

WARNING!

In order to avoid irreversible equipment damage, move carefully, do not overturn, prevent rain, do not

stack, and avoid packaging and loaded goods from collisions and heat sources.

Moving

WARNING!

Before disposing of the package, check all machine parts such as accessories, tools, instructions.

III. Structure

Appearance

Figure 1

Emergency stop

USB port

Aging chamber

Controller

Printer

-7 -

Aging chamber

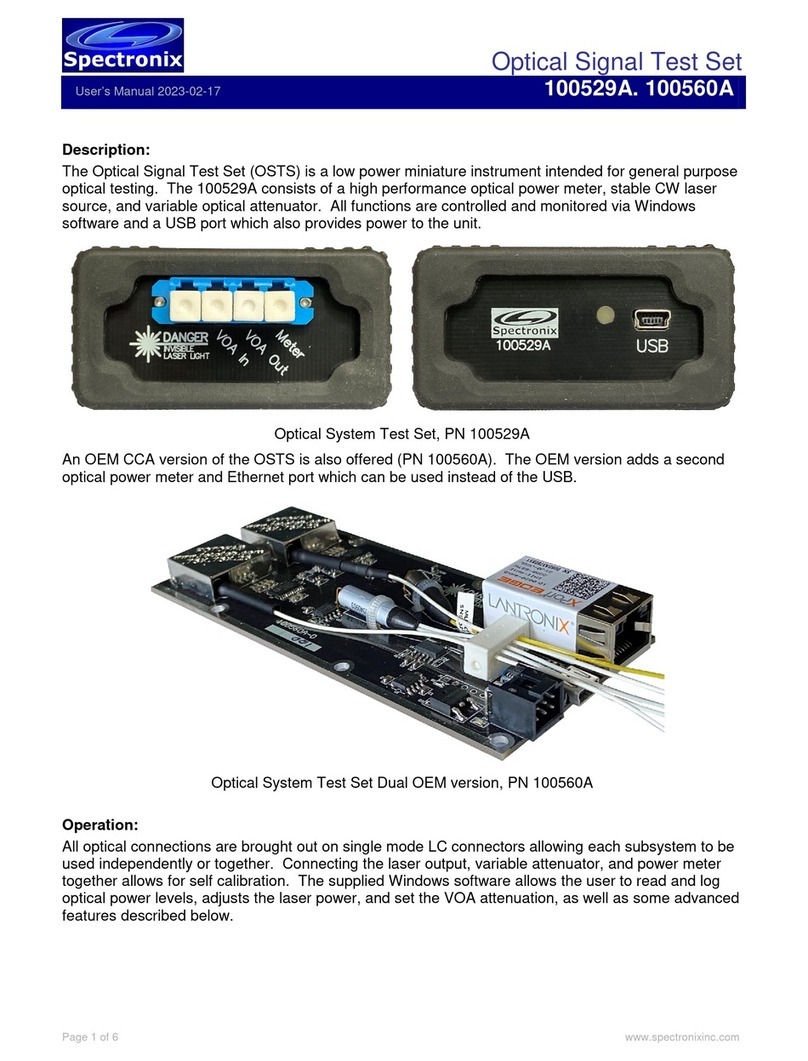

Figure 2

The structure of the aging chamber is shown in Figure 2, which mainly provides a high temperature

and high pressure environment for the rapid aging of asphalt samples. The maximum heating

temperature is 110°C and the maximum pressure is 2.4MPa. When the pressure is higher than

2.4MPa, the pressure relief valve is opened to prevent excessive pressure in the aging chamber.

When closing the cover of the aging chamber, the sealing ring needs to be installed, and the cover

of the aging chamber should be pressed tightly with bolts to prevent air leakage during the test and

affect the test results.

WARNING!

For safe use, it is forbidden to open the temperature and pressure calibration port when the aging

chamber is under pressure!

Figure 3

Sealing ring

Cover

Sample dishes

Temperature

sensor

Temperature and pressure

calibration port

Pressure relief

valve

Handle

-8 -

Rack

Figure 4

As shown in Figure 4, the rack is mainly used for placing sample dishes during pressure aging, and

a maximum of 10 sample dishes can be placed in one test.

In order to prevent scalding the skin, it is necessary to wear high-temperature protective gloves when

operating, and use a special tool (shown in the right picture) to remove it.

IV. Hardware

Figure 5

V. Device connection

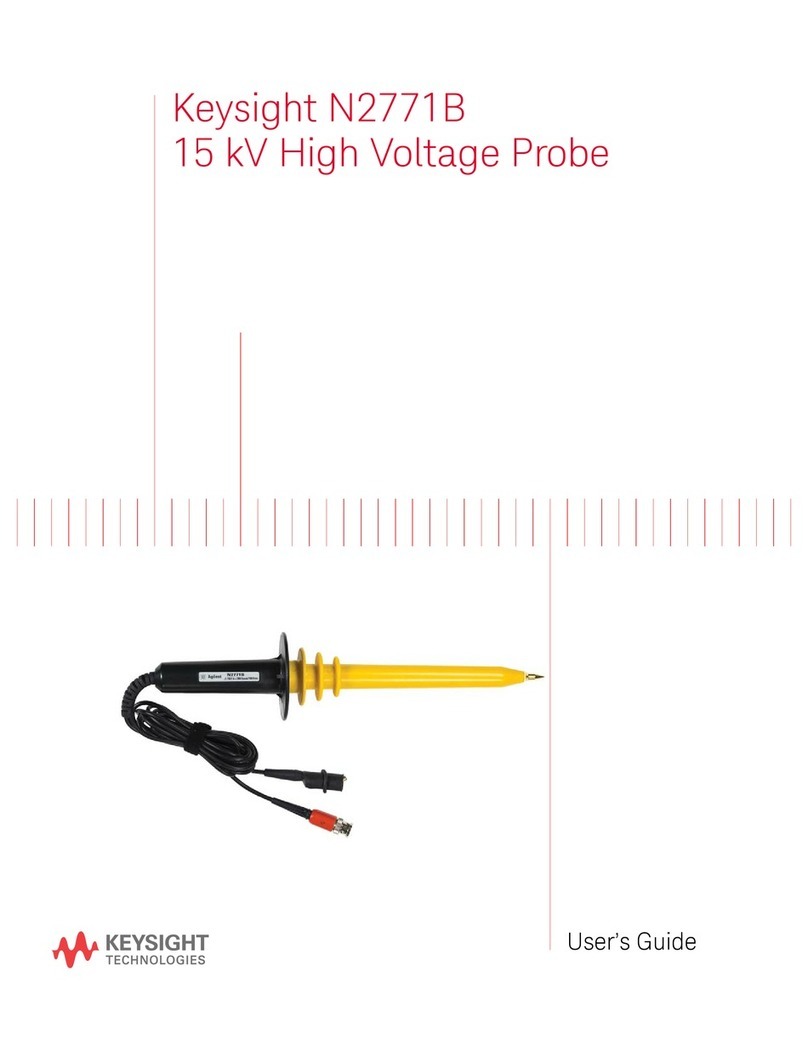

Figure 6

Pressure regulator

Connection device

side

Connect tank

side

-9 -

Figure 7

When the equipment is installed, the pressure reducing valve assembly shown in Figure 6 needs to

be connected between the equipment and the air storage tank. Adjust the air pressure entering the

device through the pressure adjustment handle, so that it can be between 3Mpa and 4Mpa.

VI. Software

Main interface

Figure 8 Main interface

Temperature sensor

High pressure air pipe

Power connector

-10 -

Turn on the device and enter the main interface, as shown in Figure 8.

[Parameter Settings]: Click to enter the parameter setting interface, as shown in Figure 9.

[Start Test]: Click to enter the start test interface, as shown in Figure 10.

[Device Debugging]: Click to enter the device debugging interface.

Parameter setting interface

Figure 9 Parameter setting interface

[Aging time]: Used to set the pressure aging time, unit: min.

[Aging temperature]: It is used to set the temperature of the aging chamber during pressure aging,

unit: ℃.

[Aging pressure]: It is used to set the pressure of the pressure aging chamber during the test, unit:

MPa.

[Pressure correction coefficient]: It is the ratio of the actual pressure in the aging chamber to the

measured value of the pressure sensor.

-11 -

[Temperature correction coefficient]: It is the ratio between the actual temperature of the aging

chamber and the measured value of the temperature sensor.

Other parameters have been set when the equipment leaves the factory. For the accuracy of the

temperature during the test, it is not recommended to adjust. If adjustment is required, please

contact the after-sales personnel and operate under the guidance of the after-sales personnel.

[Parameters download]: After setting the relevant parameters, click this button to download the

parameters to the control card.

[Return]: Click this button to return to the main interface.

PAV Pressure Aging Process Interface

Figure 10 PAV aging process interface

The PAV aging process interface is shown in Figure 10.

[Temperature]: Display the current actual temperature of the aging chamber in °C.

[Pressure]: Display the current actual pressure of the aging chamber in MPa.

-12 -

[Aging time]: The duration of the aging test.

[Overtemperature]: The accumulative time when the temperature exceeds the set temperature limit.

[Undertemperature]: The accumulative time when the temperature is lower than the set temperature

limit.

[Overpressure]: The accumulative time when the pressure exceeds the set pressure limit.

[Underpressure]: The accumulative time when the pressure is lower than the set pressure limit.

[Preheat]: Start and stop of aging chamber temperature control. After clicking, the word changes to

“heating” in red, to indicate that the temperature is being controlled, click the button again to stop.

[Pressurize]: Start and stop of aging chamber pressurization. After clicking, the "Pressurize" changes

to “Pressurizing” in red, to indicate that it is pressurizing, click the button again to stop.

[Depressurize]: Start and stop of aging chamber depressurization. After clicking, the " Depressurize"

changes to “Depressurizing” in red, to indicate that it is depressurizing, click the button again to stop.

[Graph]: Click this button, the temperature, pressure, and heating power trend curve will be displayed

on the interface, and the relevant data will be displayed at the same time.

[Print]: Click to print the test result.

[Return]: Click to return to the main menu.

Graph interface

The graph interface is shown in Figure 11. This interface displays aging time, aging chamber

temperature and pressure in real time, and simultaneously displays temperature-time and pressure-

time curves.

The temperature display range (℃) can set the display range of the temperature on the left vertical

axis in the coordinate system.

The pressure display range (kPa) can set the display range of the pressure on the right vertical axis

in the coordinate system.

-13 -

[Data List]: Click this button to enter the test data list interface, as shown in Figure 12.

[Return]: Return to the start test interface.

Figure 11 Graph interface

Data list interface

This interface displays the temperature and pressure values during the entire test process. Data is

recorded every 5 seconds. The entire process data can be exported to a USB flash drive.

[Export to U disk]: Insert the U disk into the USB port and click this button to import the process data

of the current test to the U disk.

[Graph]: Click this button to return to the data curve interface.

[Return]: Return to the start test interface.

-14 -

Figure 12 Data list interface

VII. Calibration

Temperature calibration

Aging chamber temperature calibration method: When the pressure of the aging chamber is

atmospheric pressure, open the threaded plug of the temperature calibration port on the aging

chamber cover (Figure 13), and insert the standard temperature sensor into the aging chamber for

temperature calibration.

Pressure calibration

Aging chamber pressure calibration method: open

the aging chamber cover, connect the standard

pressure sensor to the interface shown in Figure 10

(same as the temperature calibration port), and

then calibrate the pressure.

Figure 13

VIII. Operation

Temperature and pressure

calibration port

-15 -

WARNING!

Be careful not to crush your fingers when opening or closing the aging chamber cover!

WARNING!

Wear high temperature resistant gloves during operation to prevent burns!

1. Turn on the power and turn on the panel power switch.

2. Open the control software and set the relevant test parameters on the parameter setting

interface (as shown in Figure 8).

3. Click the "Preheat" button on the "PAV aging process" interface, and when the temperature

reaches the preheating temperature, prepare the sample according to the specification

requirements and put it into the sample dishes.

4. After reaching the preheating temperature, open the aging chamber, quickly take out the rack,

and place the sample dishes on the rack in turn.

5. Put the sample dishes and the rack into the aging chamber together, close the cover of the aging

chamber, and lock it with bolts.

6. Click the "Preheat" button on the "PAV aging process" interface. After the temperature reaches

the set preheating temperature, open the air supply to supply the air pressure of

2.1MPa±0.1MPa. Click the "Start Aging" button to maintain the temperature and air pressure in

the aging chamber for 20h±10min.

7. After the set aging time is reached, the air will be exhausted automatically, the pressure in the

aging chamber will quickly decrease to the same as the external pressure, and close the ball

valve of the air supply.

8. Open the aging chamber, take out the rack and sample dishes, and close the cover of the aging

chamber.

9. Turn off the power switch and cut off the power supply of the device.

IX. Maintenance

Equipment inspection

-16 -

All maintenance operations, inspections and controls must be performed by qualified personnel who

know the equipment and its construction. All operations are only possible when the device is turned

off and disconnected from the power source.

Only original spare parts may be used for this device, the manufacturer will not be held liable for any

damages and the warranty period will automatically be voided if non-original spare parts are used.

Daily inspection

Check the sealing ring of the aging chamber for permanent extrusion deformation, damage and aging,

and replace it in time if there are any of the above conditions.

Periodic inspection

Check the equipment regularly for air leaks.

Regularly (six months) replace the sealing ring of the aging chamber.

-17 -

Table of contents

Other C-Tech Test Equipment manuals