2

Usage for the intended purpose ..............................................................................................................4

Safety note .............................................................................................................................................4

PED (Pressure Equipment Directive)........................................................................................................5

ATEX (Atmosphère Explosible).................................................................................................................5

Note on the Declaration of Conformity / Declaration by the Manufacturer ..........................................5

Important Notes

Explanatory Notes

Scope of supply......................................................................................................................................5

Description .............................................................................................................................................6

Function .................................................................................................................................................6

Corrosion resistance...............................................................................................................................7

Sizing .....................................................................................................................................................7

NRG 16-19, NRG 16-27, NRG 16-28 .......................................................................................................7

Test chamber VKE 16-1, VKE 16-A ..........................................................................................................8

Test chamber VKE 26..............................................................................................................................8

Name plate / marking .............................................................................................................................9

Notice.....................................................................................................................................................9

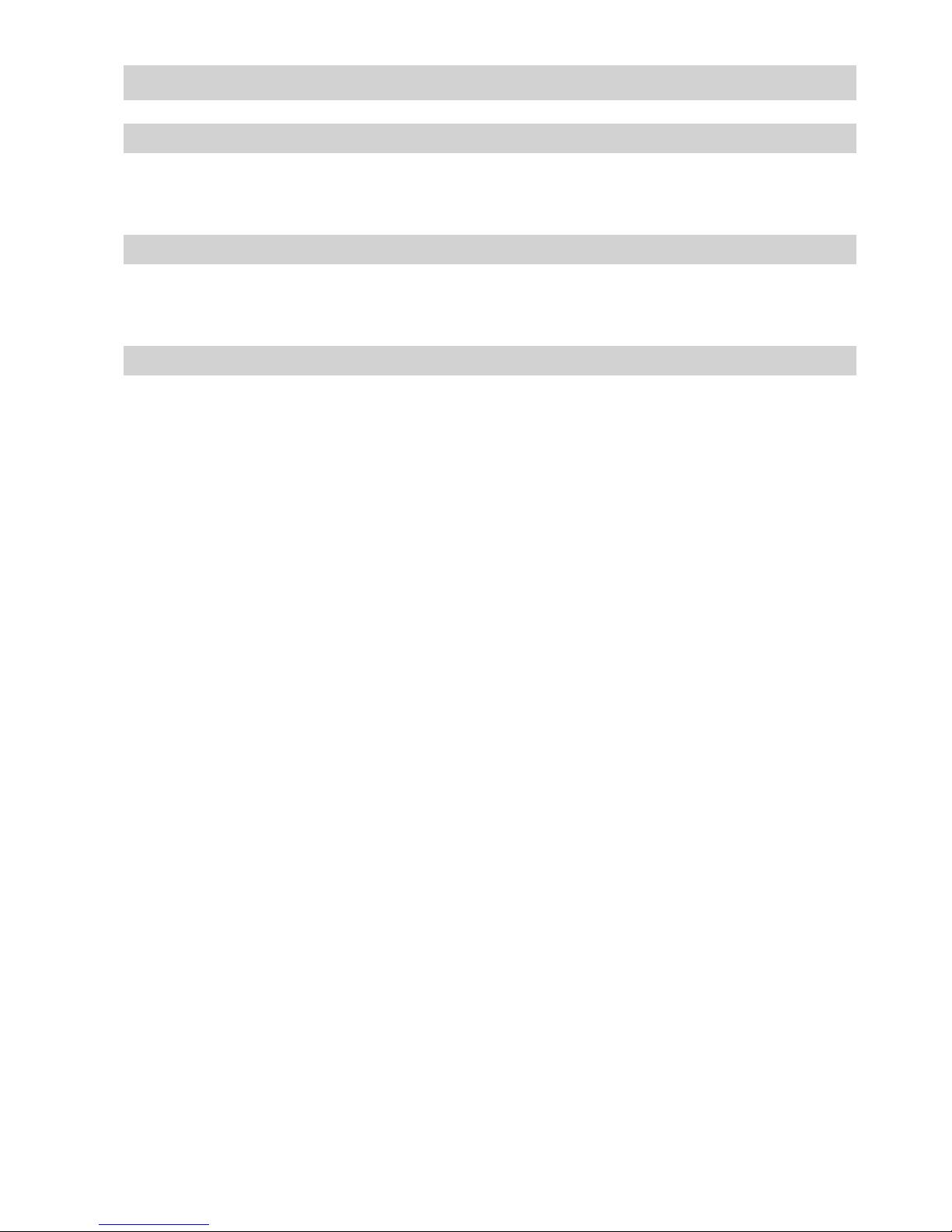

Dimensions of NRG 16-19, NRG 16-27, NRG 16-28 ..............................................................................10

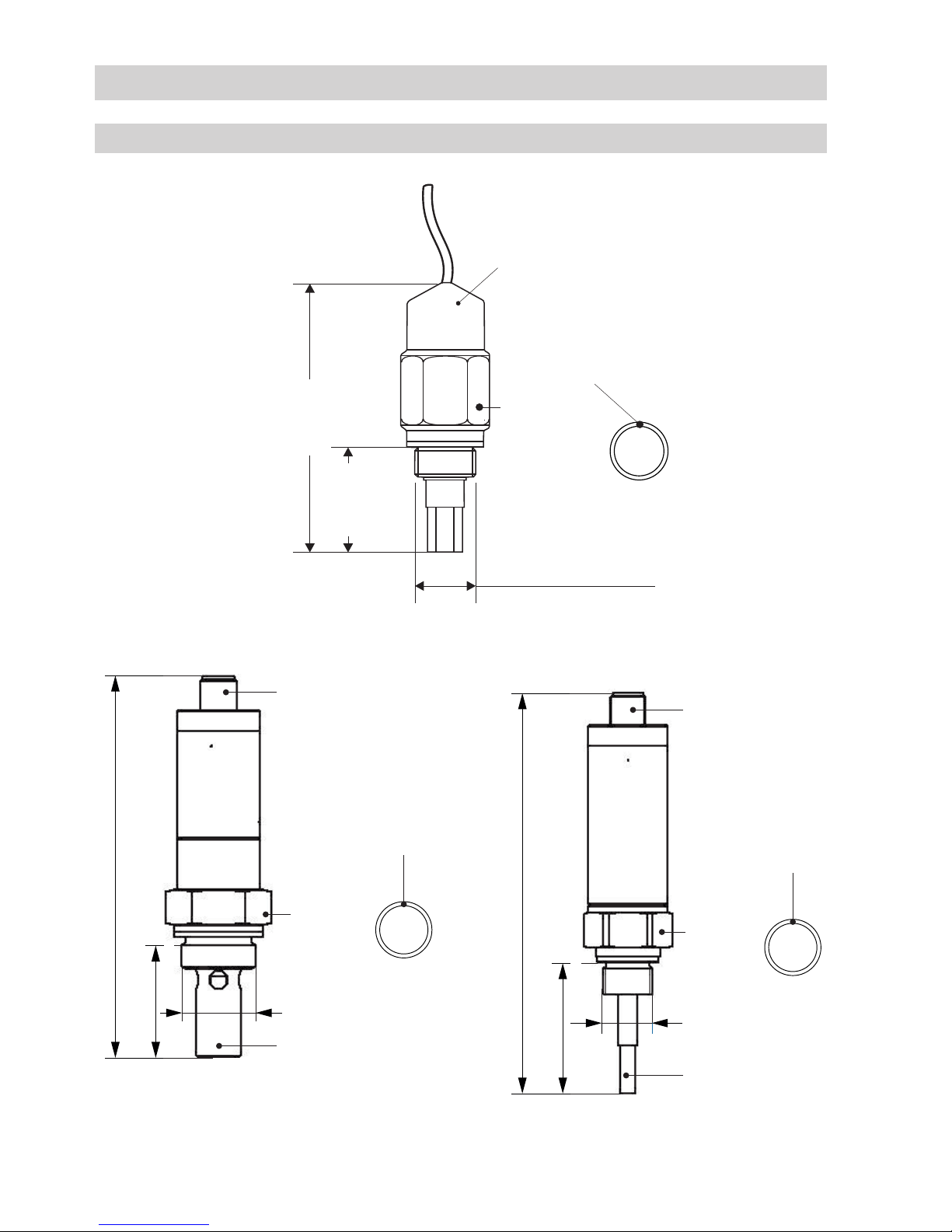

Dimensions of test chamber VKE 16-1 .................................................................................................11

Dimensions of test chamber VKE 16 A ..................................................................................................12

Dimensions of test chamber VKE 26 .....................................................................................................13

Dimensions of NRG 16-28 for Rhombusline steam traps.......................................................................13

Technical Data

VKE 16-1, VKE 16-A, VKE 26 – Danger ..................................................................................................14

VKE 16-1, VKE 16-A..............................................................................................................................14

VKE 16-1, VKE 16 A Design with flanged ends.......................................................................................14

VKE 16-1 Design with screwed socket ends .........................................................................................14

VKE 16-1 Design with socket-weld ends...............................................................................................15

VKE 16-1 Design with butt-weld ends...................................................................................................15

Heat treatment of welds........................................................................................................................15

VKE 26..................................................................................................................................................15

NRG 16-19, NRG 16-27, NRG 16-28 .....................................................................................................16

Tools.....................................................................................................................................................16

Examples of installation NRG 16-19, NRG 16-27, NRG 16-28 ...............................................................17

Installation

Contents

Page