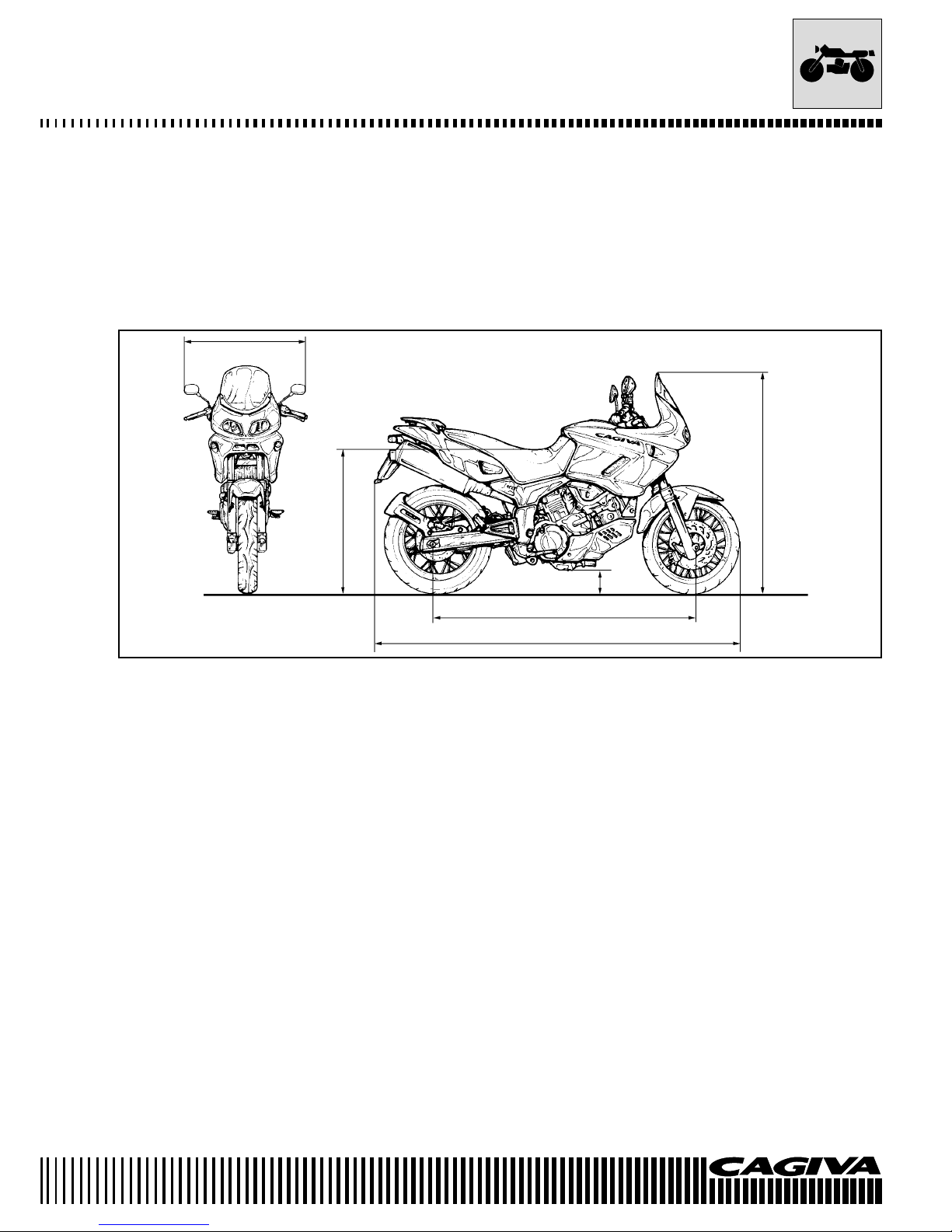

A.4

GENERAL INFORMATION

FRAME

Type ........................................................................................... Rectangular and square box section tubular framework

in highly resistant steel with box-type strengthening

supports at the fork fulcrum attachment.

FRONT SUSPENSION

Type ........................................................................................... Conventional advanced pivot hydraulic telescopic fork

with45mmdiametertubes.Telescopicmovement150mm.

Steering angle ............................................................................ 32° (left and right)

Steering head angle ................................................................... 25°

Trail ............................................................................................ 110 mm

REAR SUSPENSION

Type ............................................................................................Single hydraulic shock absorber progressively damped

with external pre-load adjustment of the spring and

extensionofthehydraulicbrakingeffect.Wheeltravel160mm.

WHEELS AND BRAKES

Front brake................................................................................. Twin disc

Rear brake ................................................................................. Single disc

Front tyre.................................................................................... Metzeler ME Z4 C – 110/80 – 18”

Rear tyre .................................................................................... Metzeler ME Z4 – 150/70 – 17”

ELECTRICAL SYSTEM

Transistorised electronic ignition

Ignition phase............................................................................. 3° before T.D.C. at 1300 rpm

Spark plugs ................................................................................ NGK CR8EK or DENSO U24ETR

Battery........................................................................................ 12v 10Ah

Generator ................................................................................... Three phase AC generator

Fuses ......................................................................................... 30/30/15/15/15/10/10A

Headlight unit ............................................................................. Main beam: condenser halogen bulb H1 12v-55w

Dipped beam: polyellipsoidal bulb H3 12v-55w

Sidelight ..................................................................................... 12v 5w

Direction indicators..................................................................... 12v 10w

Number plate light ...................................................................... 12v 5w

Brake/tail light............................................................................. 12v 21/5w

INSTRUMENT PANEL

Instrument bulb .......................................................................... 12V 1.2W

Warning lights ............................................................................ 12V 2W

FUEL/OIL/COOLANT/FORK OIL CAPACITY

Fuel tank ..................................................................................... 20 L

Engine oil: oil change .................................................................. 3100 ml

oil change with filter ................................................ 3300 ml

overhaul .................................................................. 3600 ml

Engine coolant ............................................................................ 2000 ml

Fork oil (each tube) ..................................................................... 680 ml