4

Safety Information

Safety

• Check your unit upon arrival, ensuring no damage

or lost parts occurred, during transit. Contact the

carrier’s agent, reporting any loss or damage.

Operating

Lifting Cycle • Do NOT lift an unsafe or unbalanced load.

• Do NOT use a lifter labeled with an

“Out of Service” tag.

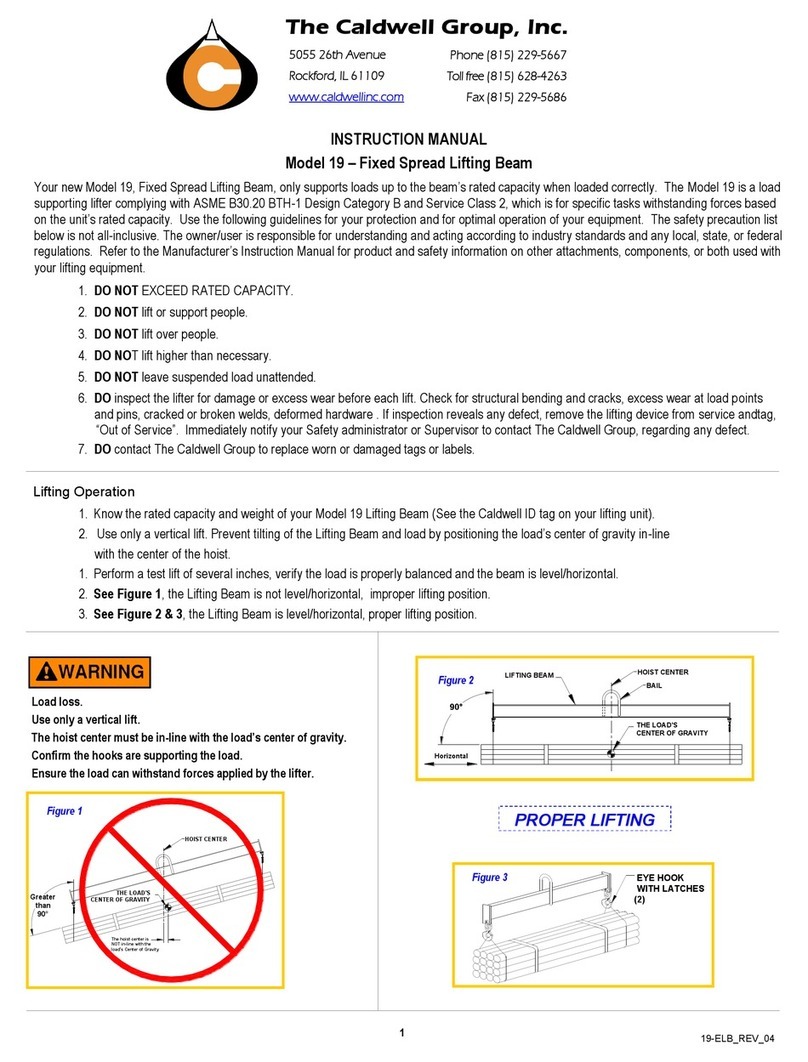

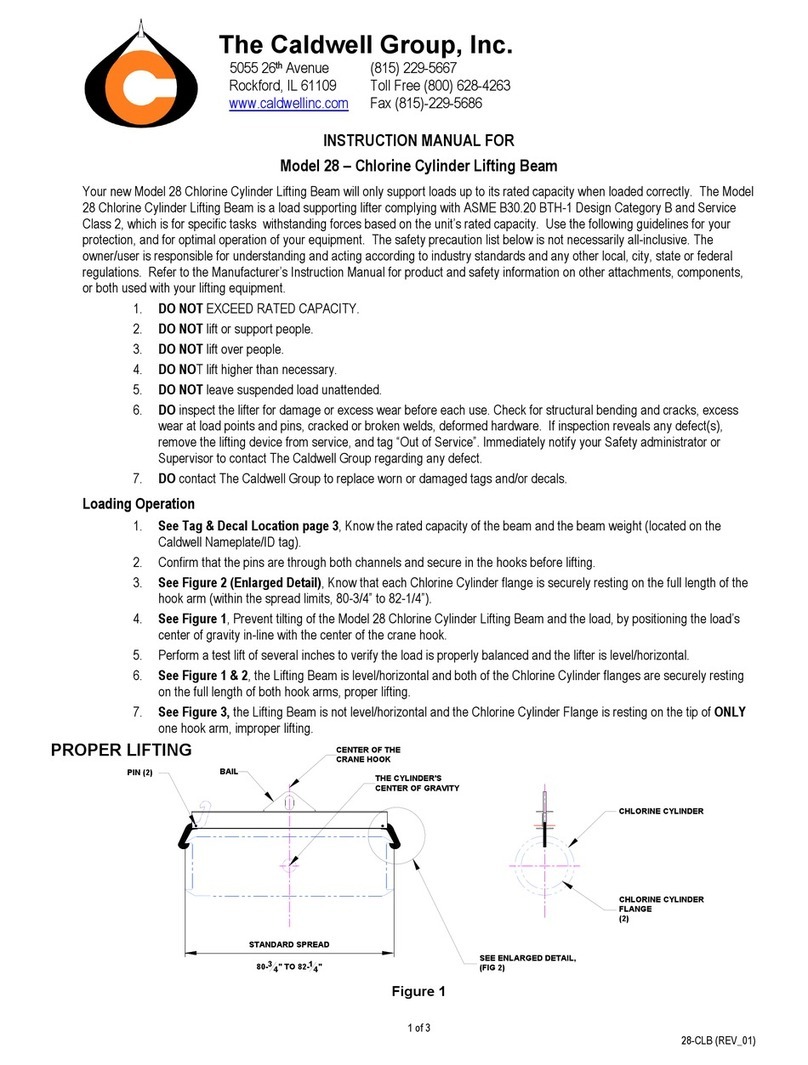

• Use ONLY a vertical lift.

• Lifting at angles less than or greater than 90

degrees voids your warranty.

• Start lifting a loaded or unloaded lifter slowly

and gently.

• Raise, lower, or transport the loaded or

unloaded lifter ONLY over specified areas.

• Inspect the load, making sure nothing can fall

from the load or lifter, during loading, lifting, or

transporting cycle—Remove any debris or loose

objects.

• Inspect the lifter, verifying all equipment

adjustments are secure and correct for the

load size and weight.

• Verify each operator is qualified or certified in

proper lifting and rigging techniques, refer to

ASME B30.9 Slings, B30.10 Hooks, and B30.26

Rigging Hardware.

• Request each operator to demonstrate proper

lifting techniques, using the Triangle Beam.

• Verify the travel path is clear.

• Barricade people from swing zones, fall zones,

and crush zones.

• Confirm the weight of the load does NOT exceed

your Triangle Beam’s rated capacity.

• Confirm the combined load and lifter weight

does NOT exceed the hoist’s rated capacity.

Receiving

• Read and understand this manual before

operating, inspecting, maintaining , or servicing

your Triangle Beam.

• Allow only qualified persons to install, operate,

inspect, and maintain your Triangle Beam.

• Confirm the Triangle Beam is

assembled correctly;

-adjustments correct for the load size and weight,

-and all components are securely fastened.

• Perform a test lift before initial use.

• Verify all lifting devices are free from twists,

kinks, or any damages.

• Validate the lifter is correctly, completely seated

in the hoist.

• Confirm the load’s center of gravity is aligned

with the hoist center —before lifting or transport-

ing the loaded lifter.

• Ensure the load can withstand forces applied by

the lifter.

• Make sure the load is secure, preventing the

load from shifting, during the lift.

• Do NOT lift loads over people.

• Do NOT lift people.

• Prohibit any person from riding on the load or

the lifter.

• Obey stop signals from anyone.

• Lift or transport only properly balanced loads.

• Confirm the lifter, loaded or unloaded, is ready

for the hoisting or transporting cycle.

• Verify the transport area is clear of people and

any physical obstructions before the lifting and

transporting cycles begin.

• Accelerate and decelerate all loads slowly and

smoothly.

Before

Operating

Operating