10|Page

Step 9: The unit is now ready for water ow. When all plumbing connecons have been

completed, slowly turn on the water supply and check for leaks. Make sure the by-pass valves

are funconing properly and that the water is owing through the unit. The most common leak

is from the o-ring not making a proper seal on the unit. For new installaons, review steps 6 and

7. For older systems drain the unit, remove the o-ring, dry it and reapply silicon grease. Reinstall

the o-ring ensuring that it is properly sealed against the unit and check again for leaks.

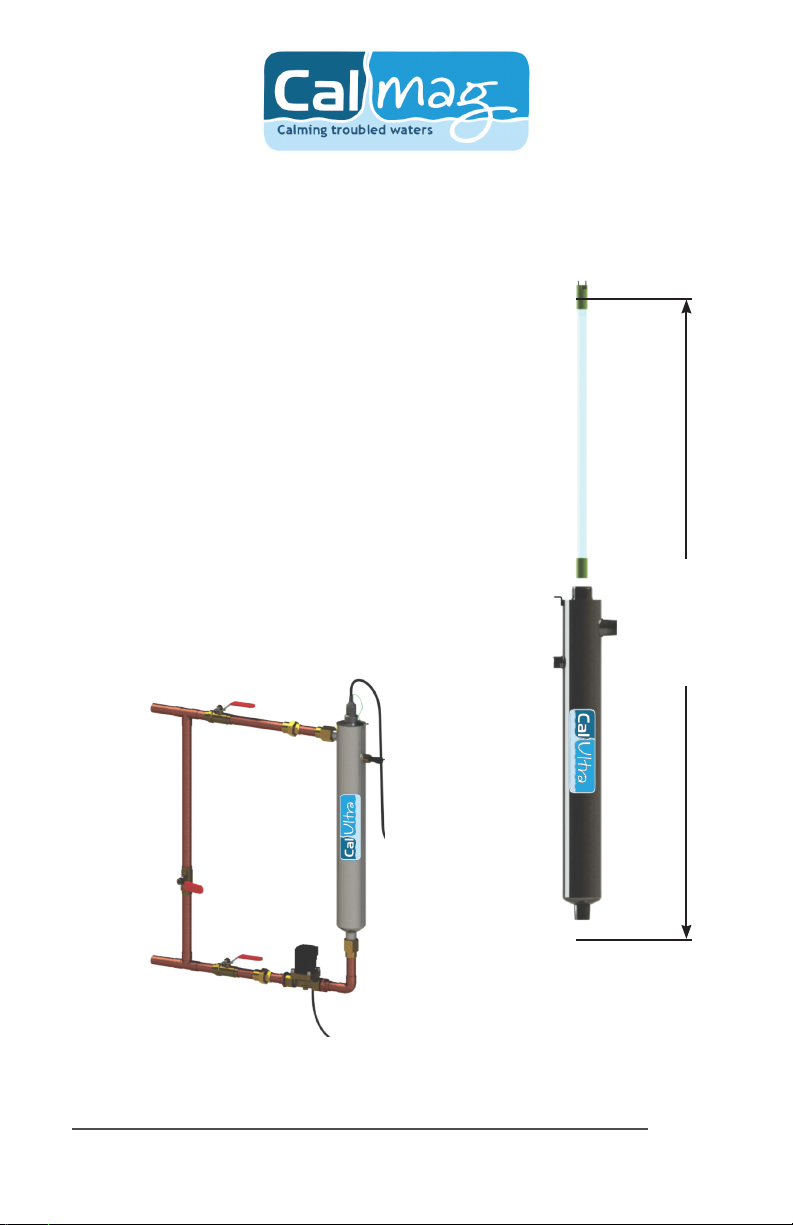

Step 10: Mount the controller (if required) to the wall so it is above or beside the reactor to

ensure that no moisture can deposit on any of the connecons (see Figure 1). Always mount the

controller vercally. For sensor systems, insert the sensor connector into the IEP port located on

the right side of the controller (Figure 6). For the sensor to be recognized by the controller, the

controller power must be plugged in last. Do not plug the controller power cord in before the

last step.

ON PRE-BUILT UNITS STEPS 11 - 14 HAVE BEEN PRE-ASSEMBLED

Step 11: Always hold UV lamps by their ceramic ends, not by the lamp quartz. Remove the lamp

from its packaging. Again, the use of coon gloves is recommended. Remove the lamp key from

the lamp’s connector and set it aside for the next step. Be careful to not touch the key’s exposed

contacts. Insert the UV lamp into the reactor, being careful not to drop it.

Figure 7a. Standard Output UV

Lamp Connecon

Step 12: Install the lamp key into the controller. The key always comes packaged with the lamp

and sits on the connector. With the key removed from the lamp, orient it so the label is upright

and facing you. The key will plug into the lamp key port on the right side of the controller (Figure

8).

Step 13: Plug the lamp connector into the lamp. Note the keying for proper alignment (see

Figure 7). Insert the lamp connector into the gland nut and turn the connector approximately ¼

turn to lock the connector to the gland nut as in Figure 9.