4Quick Start Installation Guide

807119US v1.04 11.22 G5 BCS Quick Start Guide

Quick Start Installation Guide

807119US v1.04 11.22 G5 BCS Quick Start Guide

5

SECTION 2: IMPORTANT SAFETY INSTRUCTIONS

Safety

This appliance is not intended for use by children under 8 years or persons

(including children under 8 years) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning the use of the appliance by a

person responsible for their safety. Children should be supervised to ensure

that they do not play with the appliance.

Ventilation

Keep ventilation openings, in the appliance enclosure or in the built-in

structure, clear of obstruction.

Do not use mechanical devices or other means to accelerate the defrosting

process, other than those recommended by the manufacturer.

Do not store explosive substances such as aerosol cans with a flammable

propellant in this appliance.

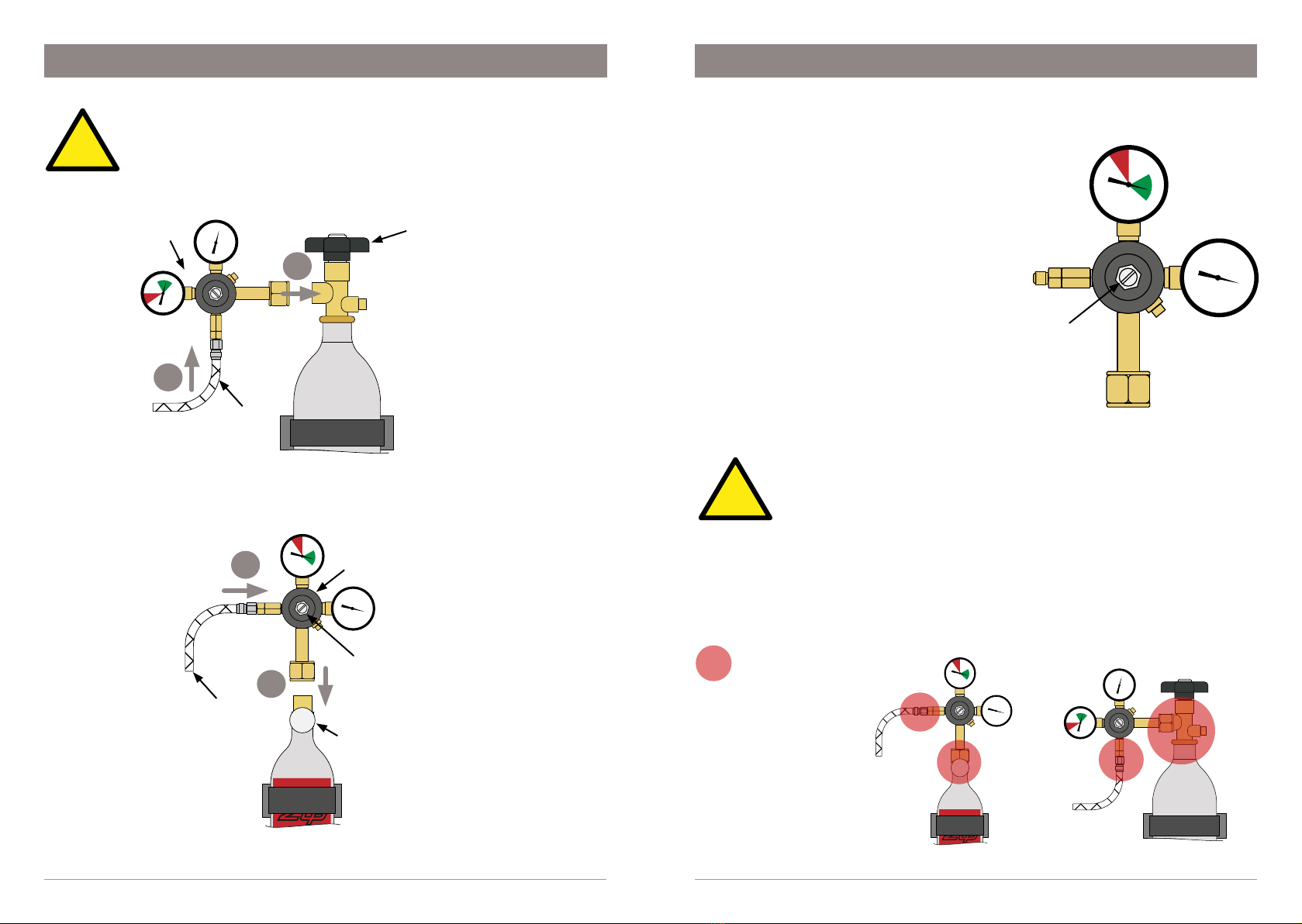

CO2

• Keep out of reach of children.

• Use according to MSDS (material safety data sheet).

• Pressurized container. Contains gas under pressure,may

explode if heated.

• Protect from sunlight.

• Do not expose to temperatures exceeding 122ºF, (50ºC).

• Do not expose to naked flame or any incandescent material.

• Do not pierce or burn, even after use. Avoid shock.

• High concentration of gas may cause asphyxiation.

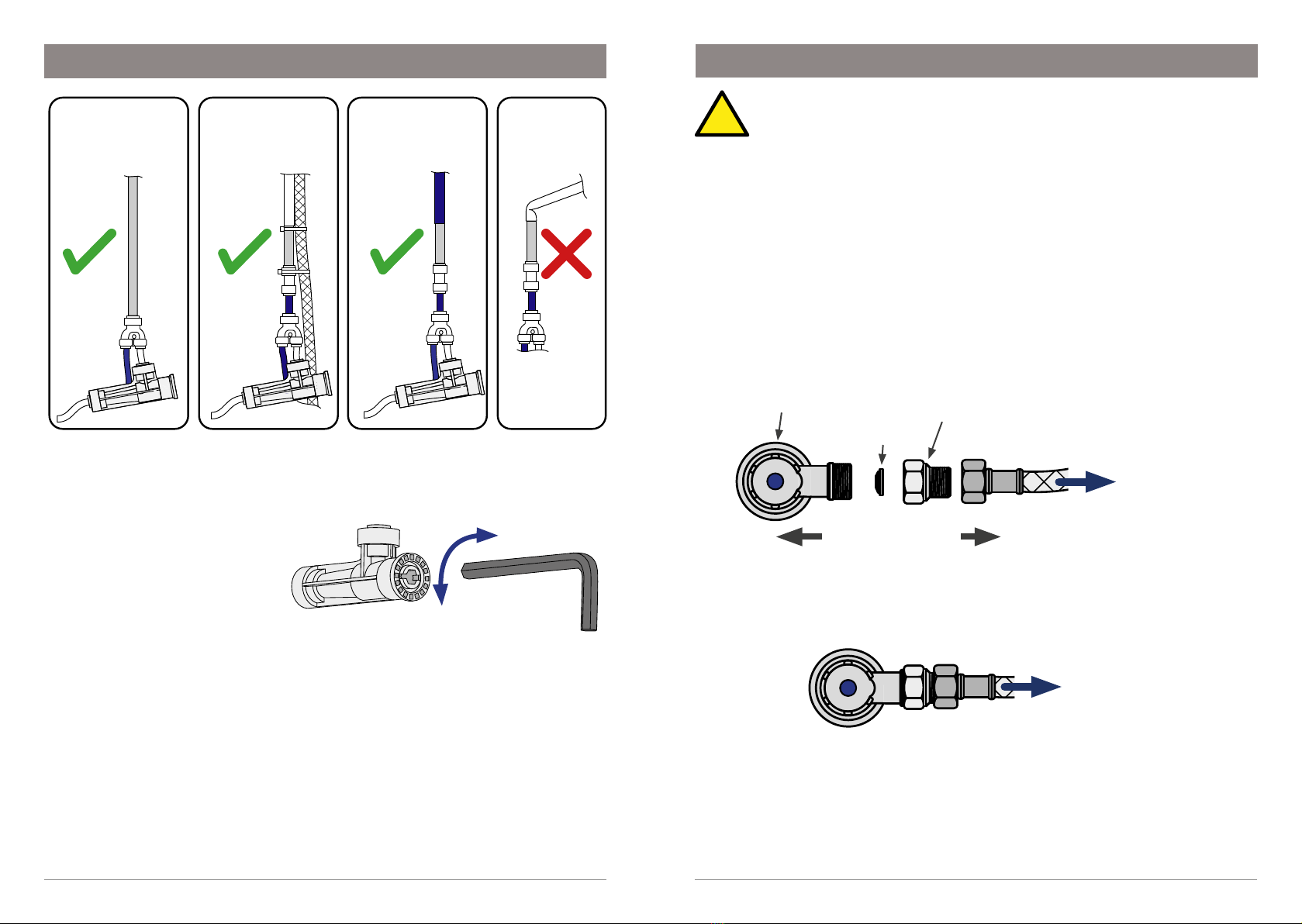

Compliance

All Plumbing and Electrical connections must comply with local,

state and federal codes.

All Plumbing and Electrical connections must be made in accordance with local

regulations.

Ensure the electrical power supply at the installation site is suitable for your

HydroTap.

HydroTap models are rated for the following installations:

• Commercial - 220-240VAC 50/60Hz or 230VAC 60Hz

• Residential (120V) - 110-120VAC 50/60Hz

SECTION 2: IMPORTANT SAFETY INSTRUCTIONS

• Use only in an upright position.

• The cylinder must be used with the supplied pressure regulator.

• Store in a location with a volume no less than 65 cubic yards (50 cubic

meters) for each 5 lb, (2.27kg) cylinder.

• If more than 1 gas cylinder containing COis present within the same

location, the recommended ventilated area should be in proportion to

the number of gas cylinders stored in that location. A ventilated area is a

non-enclosed area which could include the kitchen, living room etc.

• Refer to the gas cylinder and MSDS for a complete list of warnings

(www.na.zipwater.com).

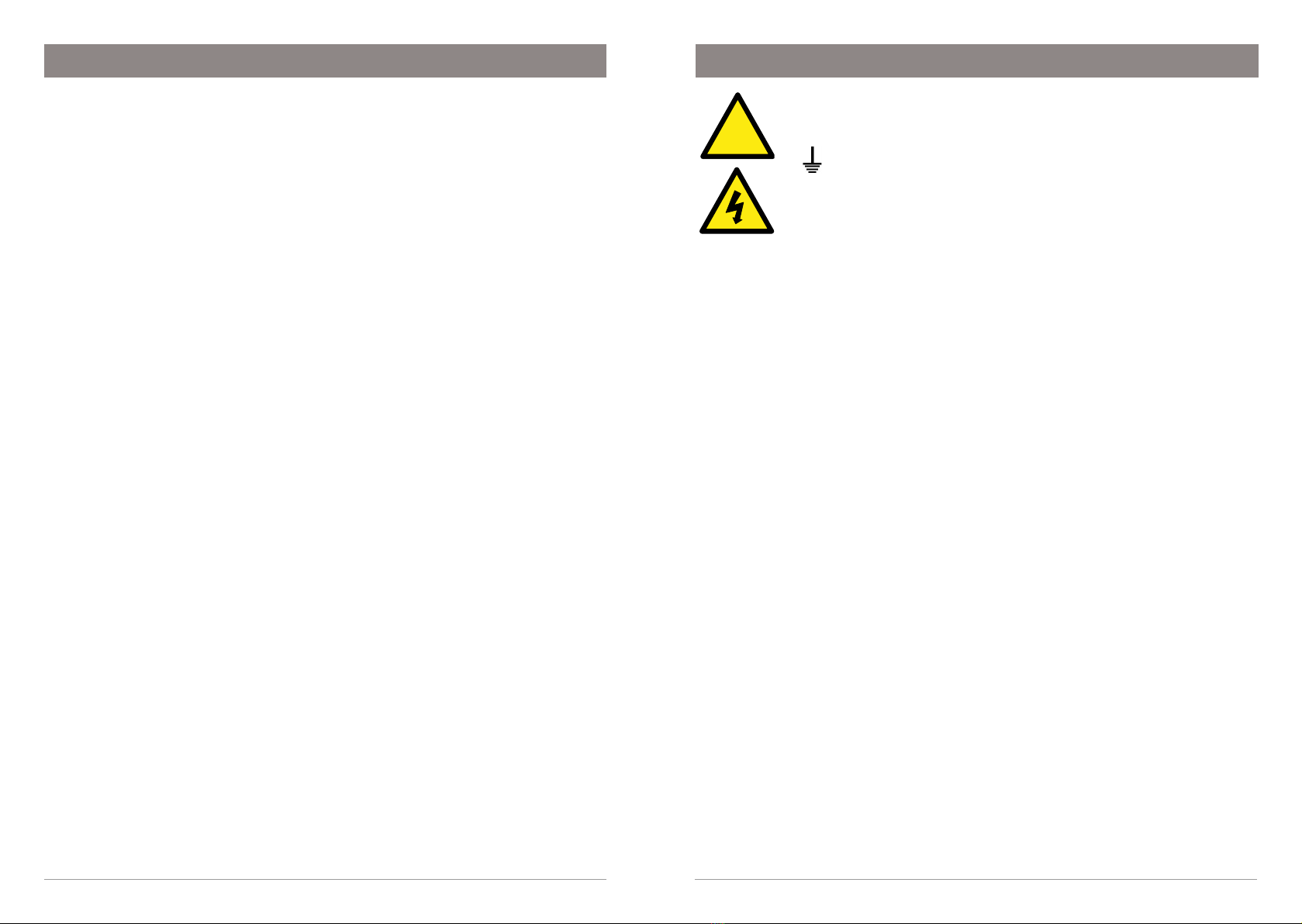

Qualifications

To avoid hazards, all installation procedures must be carried out by a

suitably qualified tradesperson. The power cable and power outlet must be

in a safe visible position for connection.

Venting

Sometimes steam and / or boiling water droplets may discharge through a

vent outlet on the tap. If not using the font, ensure the tap body is located

so the tap outlet safely dispenses into the sink bowl.

Lifting

Take care when lifting. The Command Center may exceed safe lifting

limits. If you feel this is beyond your personal capabilities, please seek

assistance with the lift. The weight of the Command Center is marked on

the packaging. Do not lift the Command Center by the front cover or any of

its connections.

Airflow

The ambient operating temperatures, when installed in a cabinet, must

be between 41 - 95ºF, (5 - 35ºC) . The system will operate satisfactorily

only with proper air ventilation. Air gaps of 2”,(50mm) on each side, and

8”,(200mm) above must be provided. See section 6 for correct ventilation

details.

Altitude

Water boils at varying temperatures at different altitudes. The HydroTap

adjusts for this during startup calibration and will recalibrate itself on a

regular basis.