INTRODUCTION

READ THIS ENTIRE MANUAL BEFORE UNPACKING AND INSTALLING THIS

PRODUCT.

Dear client,

Thank you for choosing a quality product manufactured by us.

Our expert production follows the guiding principle of the strictest quality control of each

component so as to guarantee that our products will function efficiently far into the future.

The mechanical, electrical, and electronic parts were designed and manufactured to

guarantee reliability and high-quality functioning.

The use of parts that are not original could cause functioning problems or damage to the

product. Therefore, always ask for any spare parts from authorized dealers to return the

product to perfect working order and to guarantee that it will last longer.

All the machines we manufacture are made using modern technology and systems of

tested reliability. We systematically referred to the current standards and regulations for

mechanical products, specifically the UNI standards and the CEI standards for electric and

electronic equipment. The units that are described in this manual, like all our products,

are manufactured according to criteria of good practice and in strict compliance with the

European directives and related regulations.

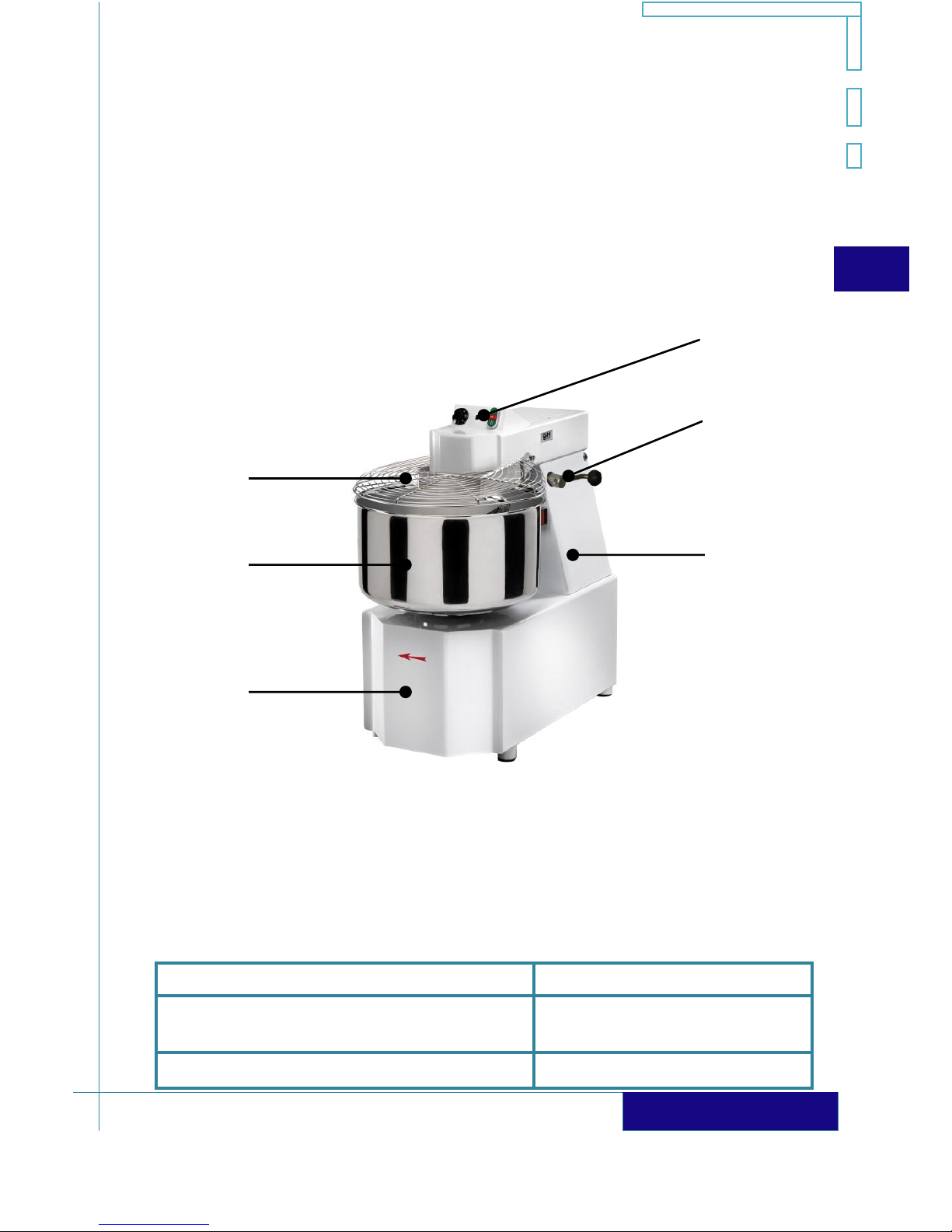

Note:

The unit that is illustrated or described could be different from your unit for

commercial or technical reasons, depending on the standards and safety

regulations in force in the different countries in Europe and in the world. The

technical specifications and dimensions, the described functioning, and any

equipment cited are not binding. The figures show a generic unit only for

illustrative purposes.

Before operating on the machine, read carefully the

technical instructions included in this manual and follow the

indications described.

Keep this manual and all the annexed literature in a readily

accessible place and known to all the users (operators and

maintenance personnel).