Advanced Graphic Data Manager Table of contents

4

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Safety information for table version (option) . . . . . . 5

1.5 IT security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.7 Notes on safety conventions and icons . . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 7

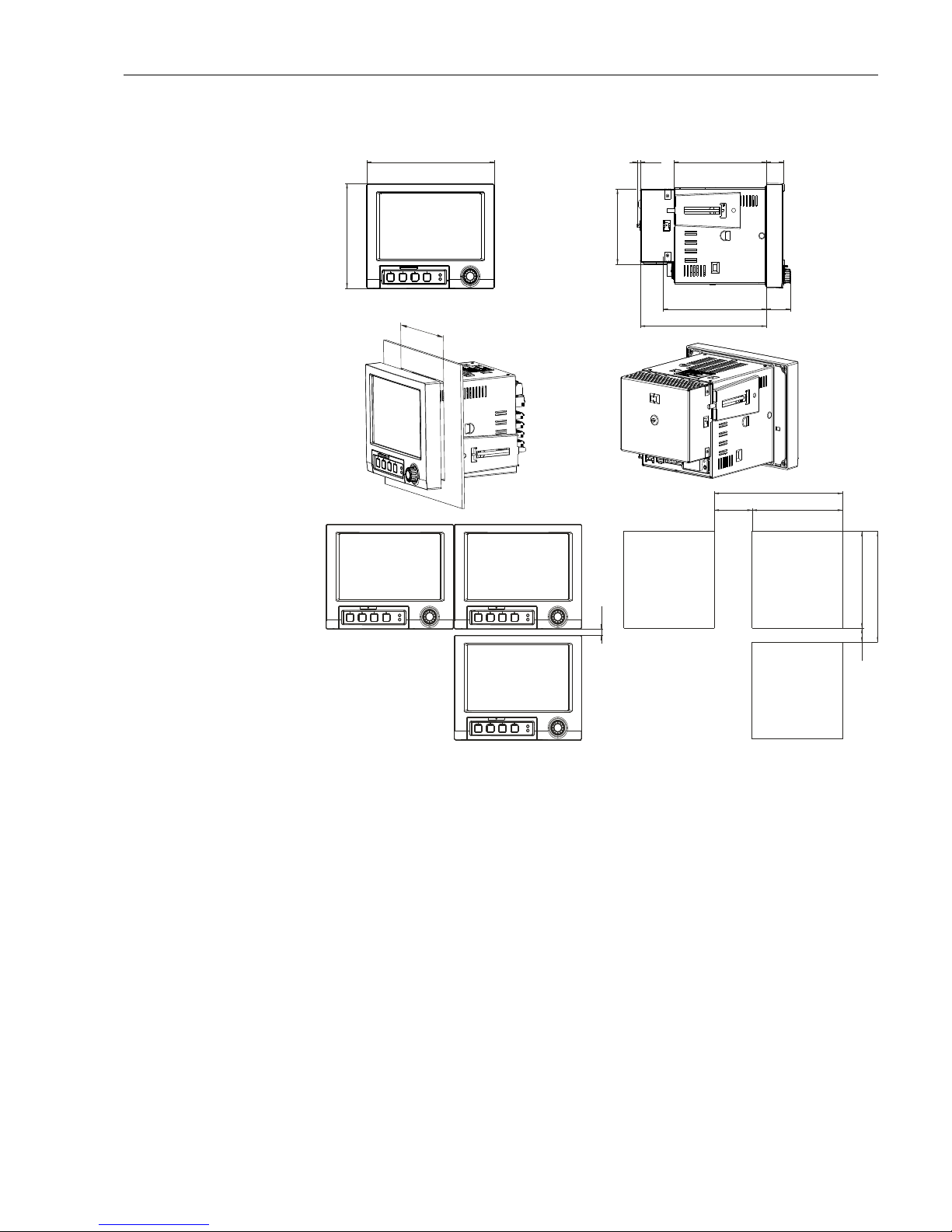

3 Installation . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Incoming acceptance, transport, storage . . . . . . . . . 8

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . 10

4 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Interface connection . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . 22

5 Operation . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Quick operating guide . . . . . . . . . . . . . . . . . . . . . 22

5.2 Display and operating elements . . . . . . . . . . . . . . . 23

5.3 Entering text and numbers . . . . . . . . . . . . . . . . . . 25

5.4 Overview of the symbols used . . . . . . . . . . . . . . . 25

5.5 Confirming error messages . . . . . . . . . . . . . . . . . . 26

5.6 Communication; installing the PC software . . . . . . 27

6 Commissioning and use during operation

31

6.1 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Switching on the device . . . . . . . . . . . . . . . . . . . . 31

6.3 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4 The Setup screen (in the main menu) . . . . . . . . . . 37

6.5 Use during operation - the "Extras" menu . . . . . . . 83

6.6 Use during operation - the main menu . . . . . . . . . 97

6.7 Settings for the mathematics channels, Formula editor

107

6.8 Meeting the requirements of 21 CFR 11 . . . . . . . 113

6.9 Measured value storage . . . . . . . . . . . . . . . . . . . 114

6.10 Data analysis and visualization using PC analysis

software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7 Maintenance . . . . . . . . . . . . . . . . . . . 117

7.1 Software update via the PC software supplied . . . 117

8 Accessories . . . . . . . . . . . . . . . . . . . . 119

8.1 Device-specific accessories . . . . . . . . . . . . . . . . . 119

9 Troubleshooting. . . . . . . . . . . . . . . . . 121

9.1 Diagnose/simulation in the main menu . . . . . . . . 121

9.2 Troubleshooting instructions . . . . . . . . . . . . . . . . 121

9.3 System error messages . . . . . . . . . . . . . . . . . . . . 122

9.4 Errors and warnings . . . . . . . . . . . . . . . . . . . . . . 122

9.5 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

9.6 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

9.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

9.8 Software history . . . . . . . . . . . . . . . . . . . . . . . . . 128

10 Technical data . . . . . . . . . . . . . . . . . . 130

10.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

10.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

10.3 Power supply / terminal diagram . . . . . . . . . . . . 134

10.4 Connection data interface, communication, operation .

135

10.5 Performance characteristics . . . . . . . . . . . . . . . . . 137

10.6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

10.7 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

10.8 Mechanical construction . . . . . . . . . . . . . . . . . . . 138

10.9 Human interface . . . . . . . . . . . . . . . . . . . . . . . . . 141

10.10 Certificates and approvals . . . . . . . . . . . . . . . . . . 145

10.11 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10.12 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147