Tripod Installation Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. General .........................................................................1

2. Specifications ..............................................................2

3. Tools List (for tripod, mast and crossarm) ...............3

4. Tripod Components.....................................................3

5. Tripod Installation........................................................4

5.1 Tripod Base...............................................................................................4

5.2 Mast ..........................................................................................................5

5.3 Installing the Guy Kit ...............................................................................9

5.3.1 Guy Duckbill Anchor Kits ............................................................11

5.3.2 Lowering Mast after Attaching Guy Wires...................................13

5.4 Staking the Tripod Feet ..........................................................................14

5.5 Tripod Grounding ...................................................................................15

5.6 Crossarm Attachment .............................................................................17

5.7 Enclosure Attachment.............................................................................17

5.7.1 Enclosure Mounting to Tripod Mast.............................................17

5.7.2 Enclosure Mounting to Tripod Leg...............................................18

6. Mounting Brackets ....................................................20

6.1 CM210 Crossarm Mounting Kit.............................................................20

6.2 CM216 Mast Mounting Kit ....................................................................21

6.3 CM220 Right Angle Mounting Kit.........................................................22

6.4 CM225 Pyranometer Mounting Stand....................................................23

6.5 CM230 Adjustable Angle Mounting Kit ................................................24

6.6 CM235 Magnetic Mounting Stand .........................................................25

6.7 RM Young Gill Radiation Shields..........................................................26

Appendix

A. Tripod Tote Bag....................................................... A-1

Figures

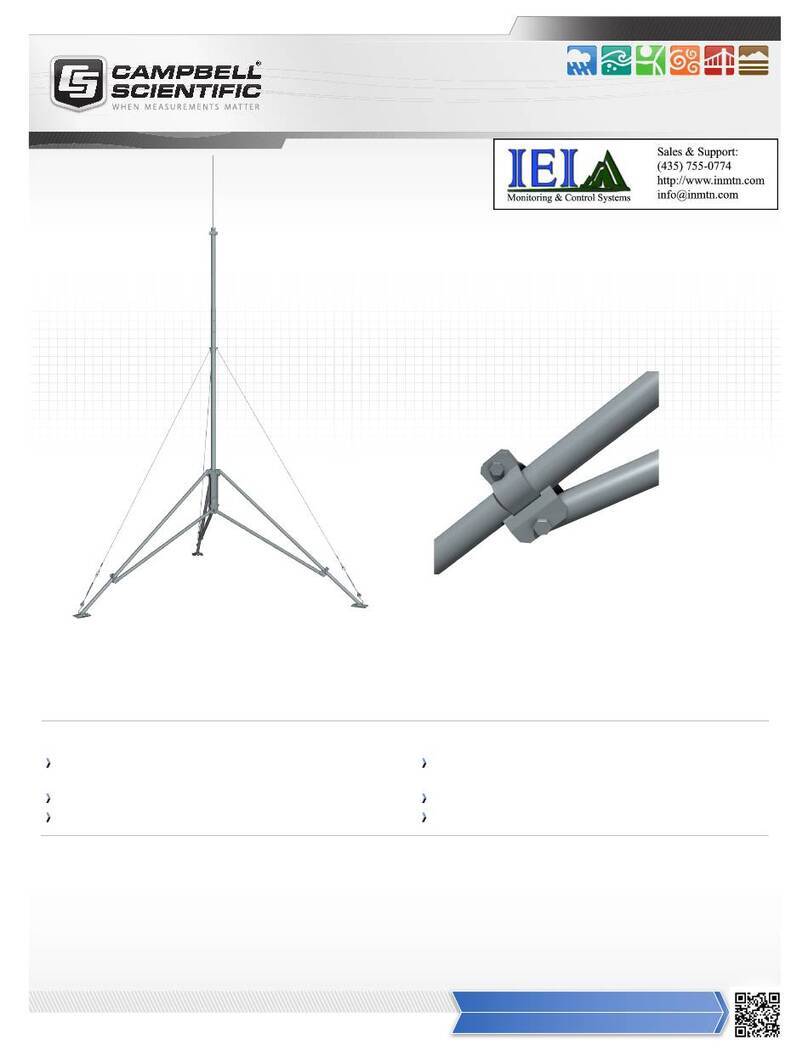

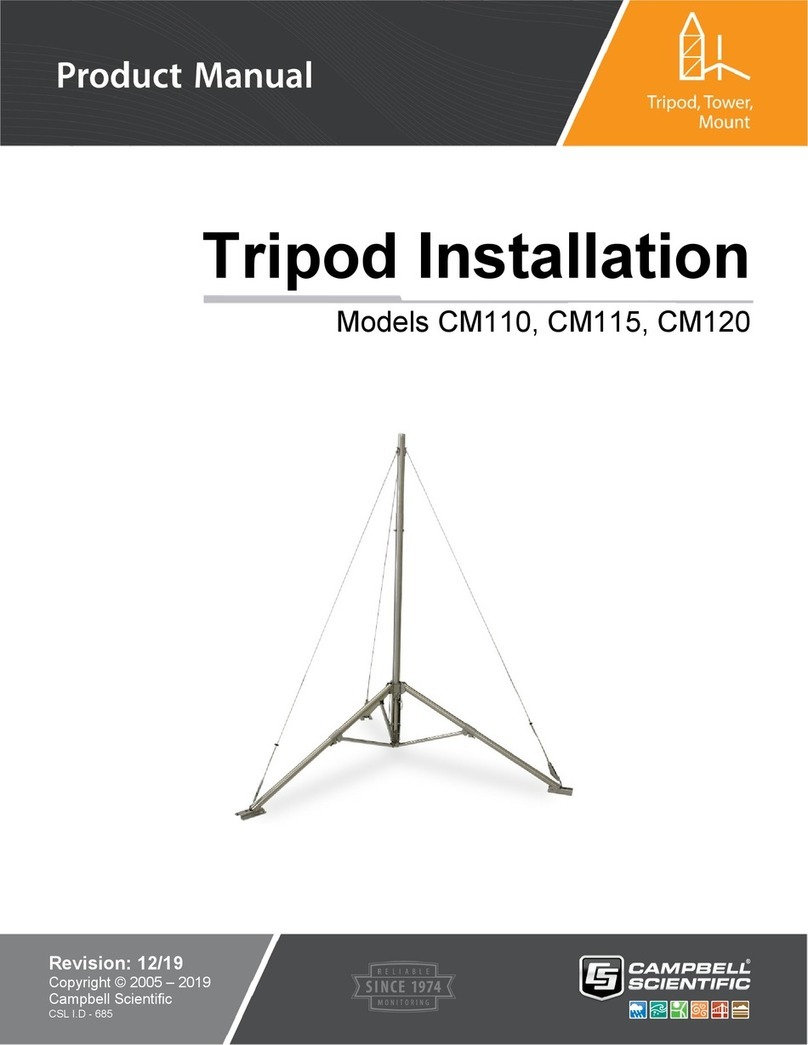

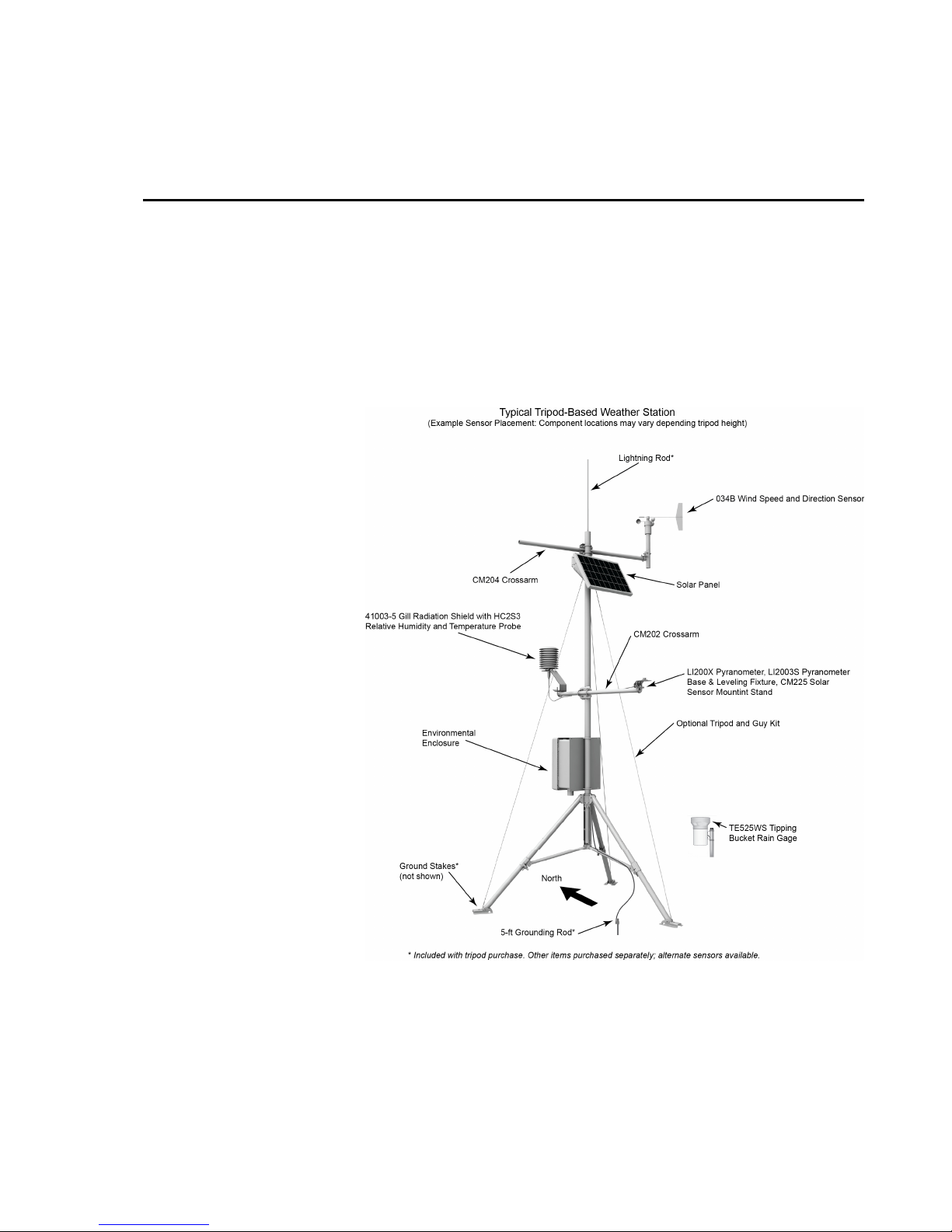

1-1. Typical tripod-based weather station.......................................................1

2-1. 60-degree guy angle ................................................................................3

4-1. Tripod components..................................................................................4

5-1. Tripod leg, slide collar components ........................................................5

i