4

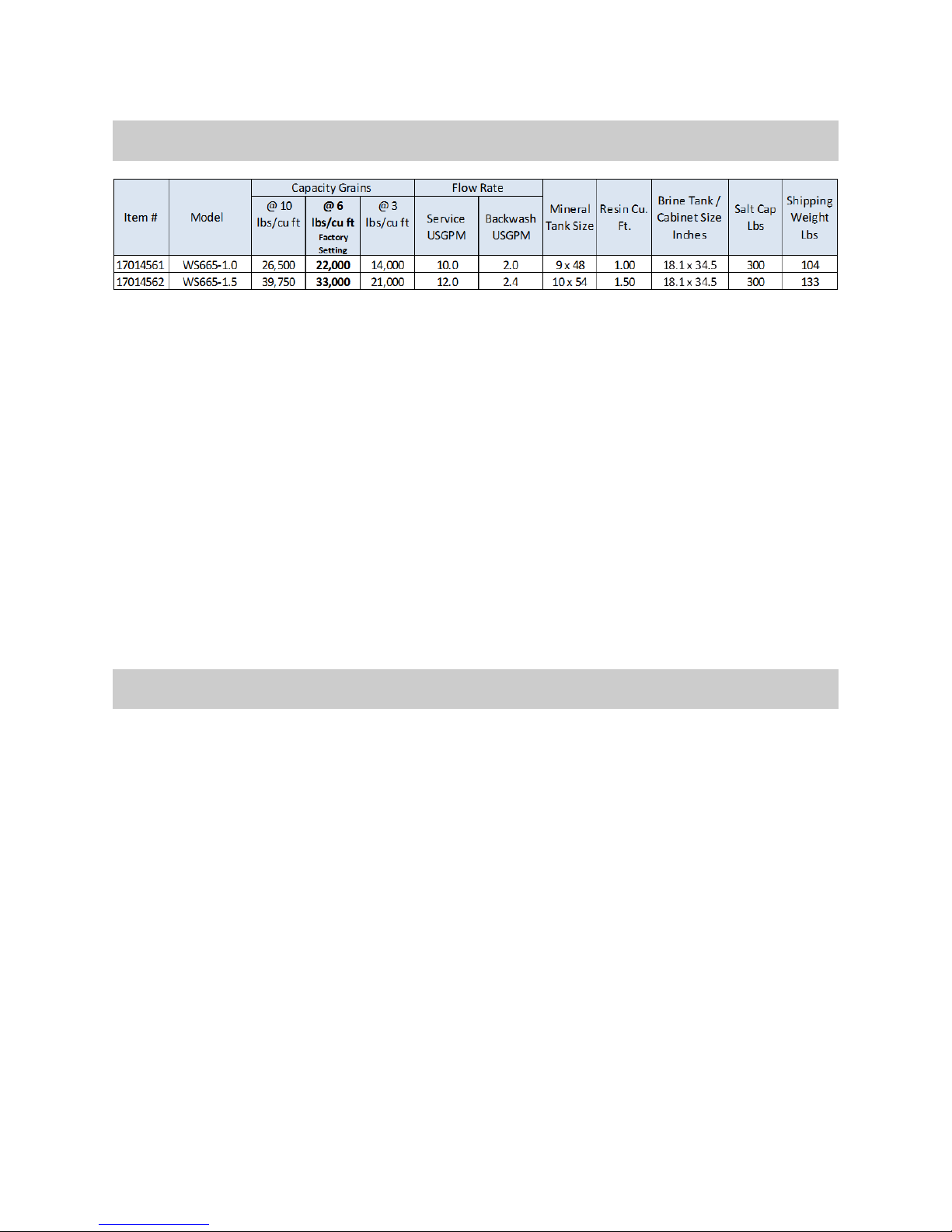

Specifications

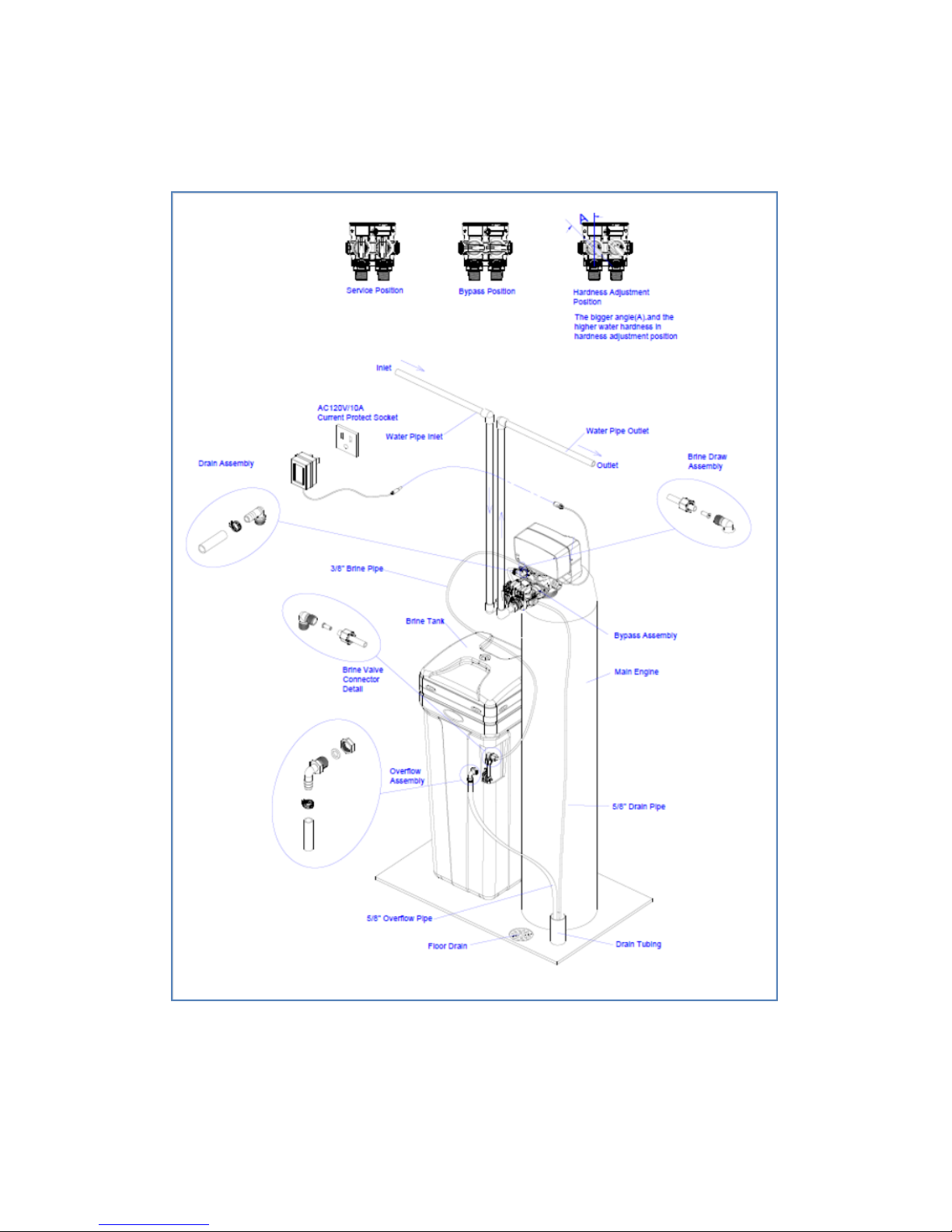

Before Starting Installation

Tools, Pipe, and Fittings, Other Materials

Pliers

Screwdriver

Teflon tape

Razor knife

Two adjustable wrenches

Additional tools may be required if modifi-

cation to home plumbing is required.

Plastic inlet and outlet fittings are included

with the softener. To maintain full valve

flow, 3/4” or 1” pipes to and from the sof-

tener fittings are recommended. You

should maintain the same, or larger, pipe

size as the water supply pipe, up to the

softener inlet and outlet.

Use copper, brass, or PEX pipe and fittings.

Some codes may also allow PVC plastic

pipe.

ALWAYS install the included bypass valve,

or 3 shut-off valves. Bypass valves let you

turn off water to the softener for repairs if

needed, but still have water in the house

pipes.

5/8” OD drain line is needed for the valve

drain. A 10’ length of hose is included.

with some models.

A length of 5/8” OD drain line tubing is

needed for the brine tank over flow fitting

(optional).

Nugget or pellet water softener salt is

needed to fill the cabinet or brine tank.

Water Temperature = Min 39°F / Max 100°F

Operating Pressure = Min 35 PSI / Max 125 PSI

Voltage = 110 volts standard

Units contain 8% Super Capacity Ion Exchange Resin

At the stated service flow rates, the pressure drop through

these devices will not exceed 15 psig.

Changing salt settings from factory setting may require

changing injector sizes to achieve stated capacities.

The manufacturer reserves the right to make product im-

provements which may deviate from the specifications and

descriptions stated herein, without obligation to change

previously manufactured products or to note the change.

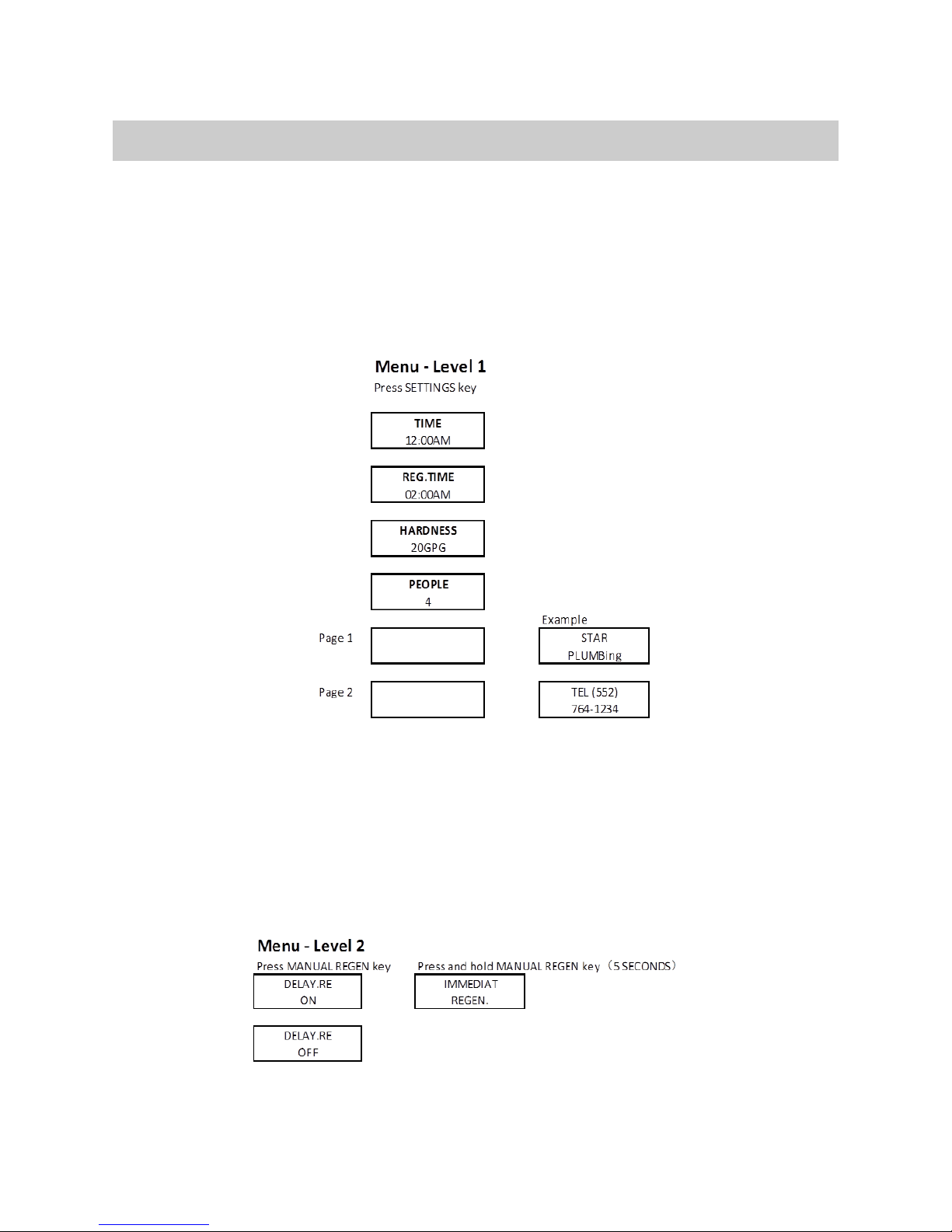

How Your Water Conditioner Works

The principle behind water softening is simple chemistry. A water softener contains resin

beads which hold electrically charged ions. When hard water passes through the softener,

calcium and magnesium ions are attracted to the charged resin beads. It's the resulting re-

moval of calcium and magnesium ions that produces soft water.

This system is controlled with simple, user-friendly electronics displayed on a LCD screen.

The main page displays the current time and the remaining gallons in meter mode or the

remaining days in calendar clock mode.