SAFETY

SAFETY PROCEDURES AND CONSIDERATIONS:

To ensure safe working conditions, persons operating and assisting with the operation of this machine

must ensure that they read and fully understand the instructions given within this manual and have

received sufficient raining in the use of the machine and the safety aspects to be observed.

Note: Persons under the age of 18 years must not operate the machine except during the course of

training under the supervision of a trained operator.

(A) POINTS TO NOTE BEFORE OPERATING OR ASSISTING WITH THE OPERATION OF THE

MACHINE.

(1) You have read and understand the operation and safety aspects of the machine and been

checked out by a qualified supervisor.

(2) The machine is supplied with full safe guarding. The machine shall not be operated unless the

safe guardings are in position and functional.

(3) Cutters/Blades are the correct type, suitable for the machine and working conditions, rotate

in the correct direction of cut, are sharp and correctly fitted.

(4) Correct spindle and speeds are selected for the cutter equipment and working conditions.

(5) Loose clothing is either removed or securely fastened back and jewellery removed.

(6) Adequate working space and lighting is provided.

(7) All dust extraction equipment is switched on, properly adjusted and working adequately.

(8) The machine is securely installed. (Refer to installation section of this manual).

(9) The machine should only be used for cutting wood or materials with physical and

technological characteristics similar to wood, and for which he chip or particle process is

similar.

(10) Only use tooling that complies with the specification described in the manual.

(B) DURING MACHINING

(1) Wear suitable protective clothing e.g, approved eye protection, ear protectors and dust masks.

Gloves shall be worn when handling tooling.

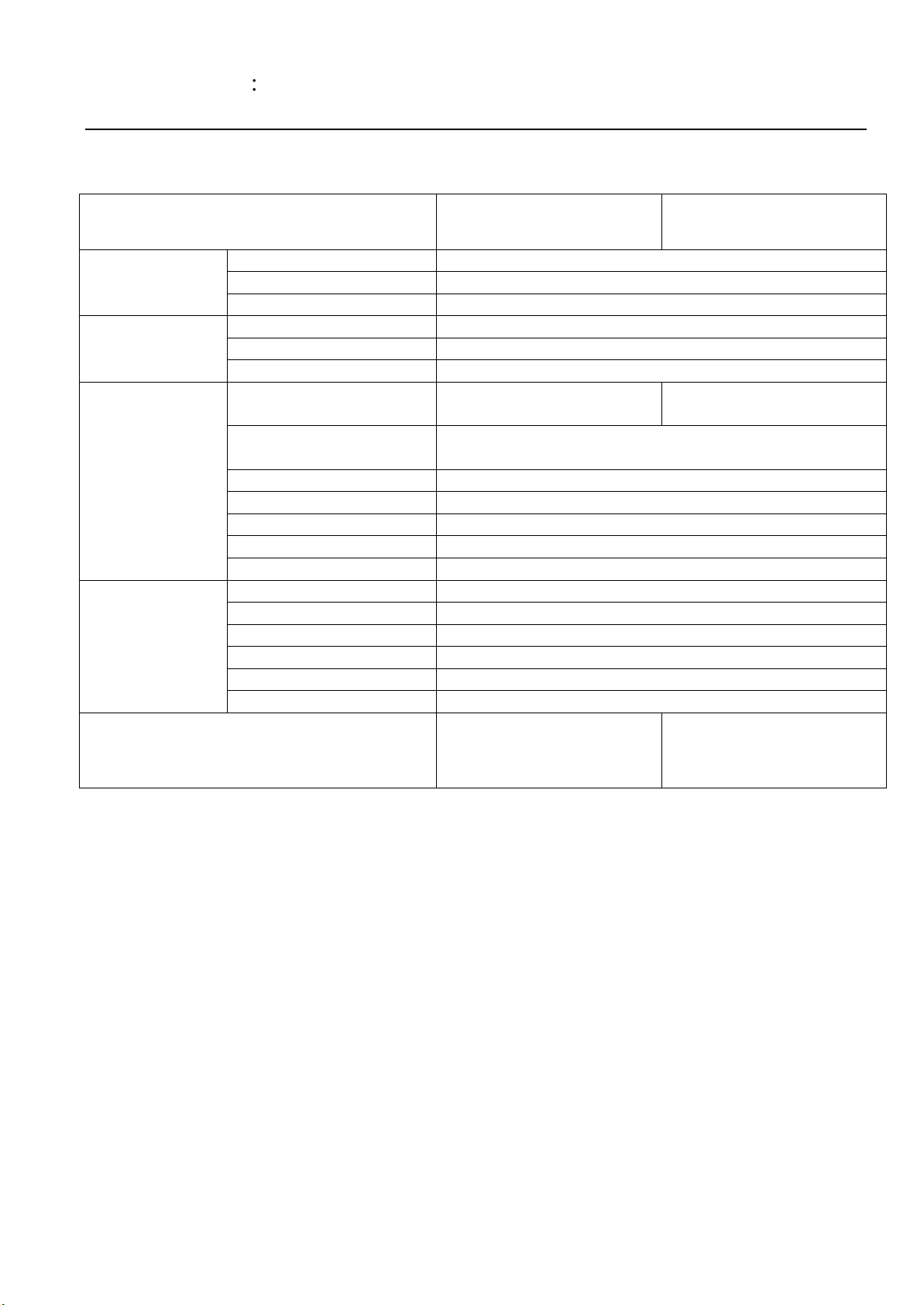

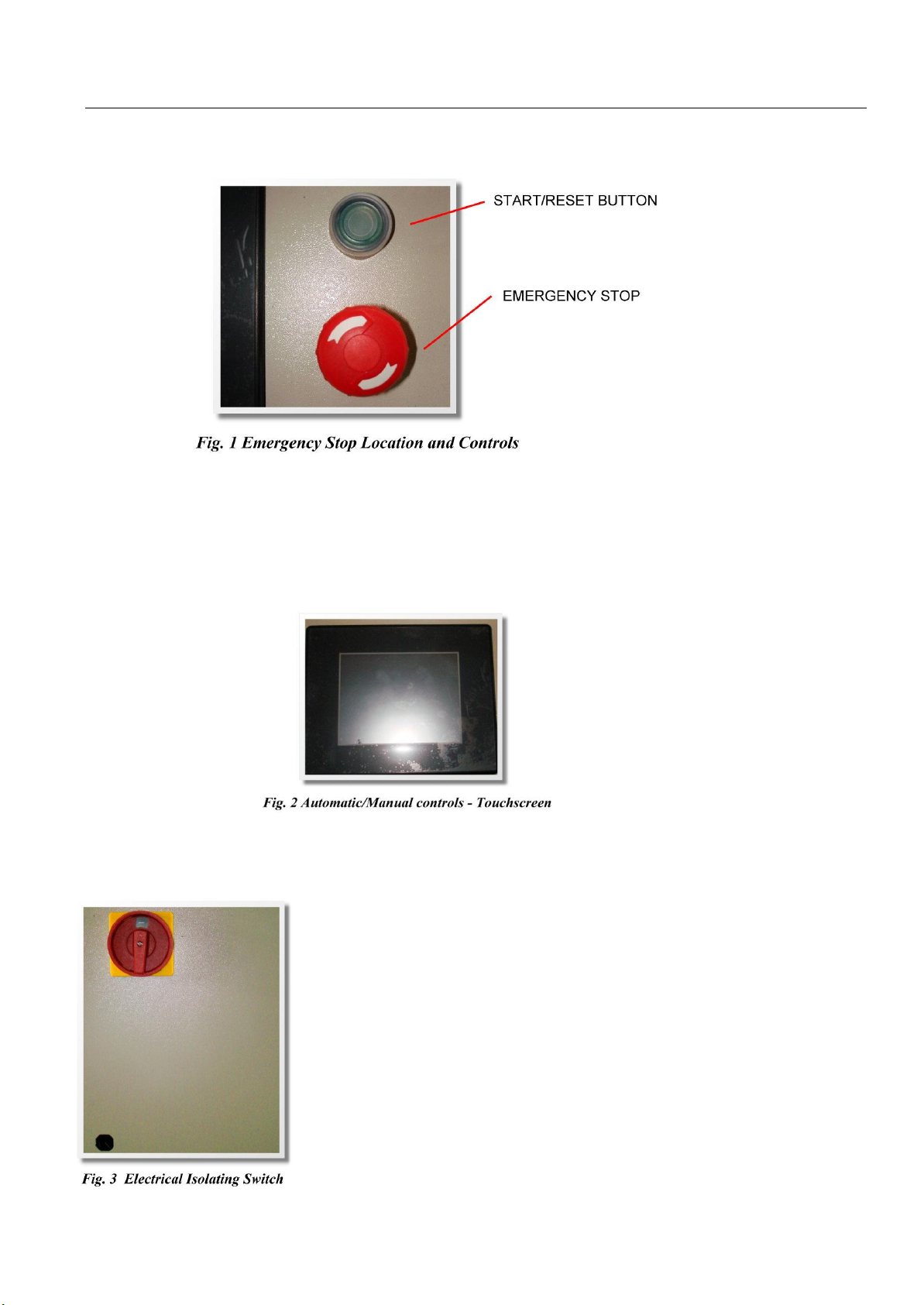

(2) Stop the machine using the emergency stop or at the mains isolator before making adjustments,

cleaning or carrying out maintenance.

(3) Keep the floor area around the machine clean and free from wood refuse. Do not allow the

floor around the machine to become slippery.

(4) Stop the machine and report immediately to a person in authority any actual or potential

malfunction or operator hazard. Do not attempt to repair or rectify the machine unless

qualified to do so.

(5) The operator must visually observe the operation of the machine on a regular basis while the

machine is turned on.

(6) Never by-pass interlocks.

WARNING:

Failure to observe correct operating procedures prior to and during operation this machine can result in

severe injury.

DO NOT attempt to operate the machine while under the influence of anything that can reduce your

alertness.

This manual describes the machine in current produce on.

We reserve the right to change the specifications without notice.