page 3 of 28

Index of contents

1 SERVICE, REPAIRS AND MODIFICATIONS...................................................................................... 4

1.1 In General .......................................................................................................................... 4

1.2 Information........................................................................................................................ 4

1.3 General Maintenance and Repair Information ................................................................. 4

1.4 Service Interval .................................................................................................................. 4

............................................................................ 6

2.4 Replacing the filter ............................................................................................................ 6

2.5 Setting of Pneumatic Components.................................................................................... 7

2.5.1 Factory Settings of Parameters ........................................................................... 7

2.5.2 Pressure regulator............................................................................................... 7

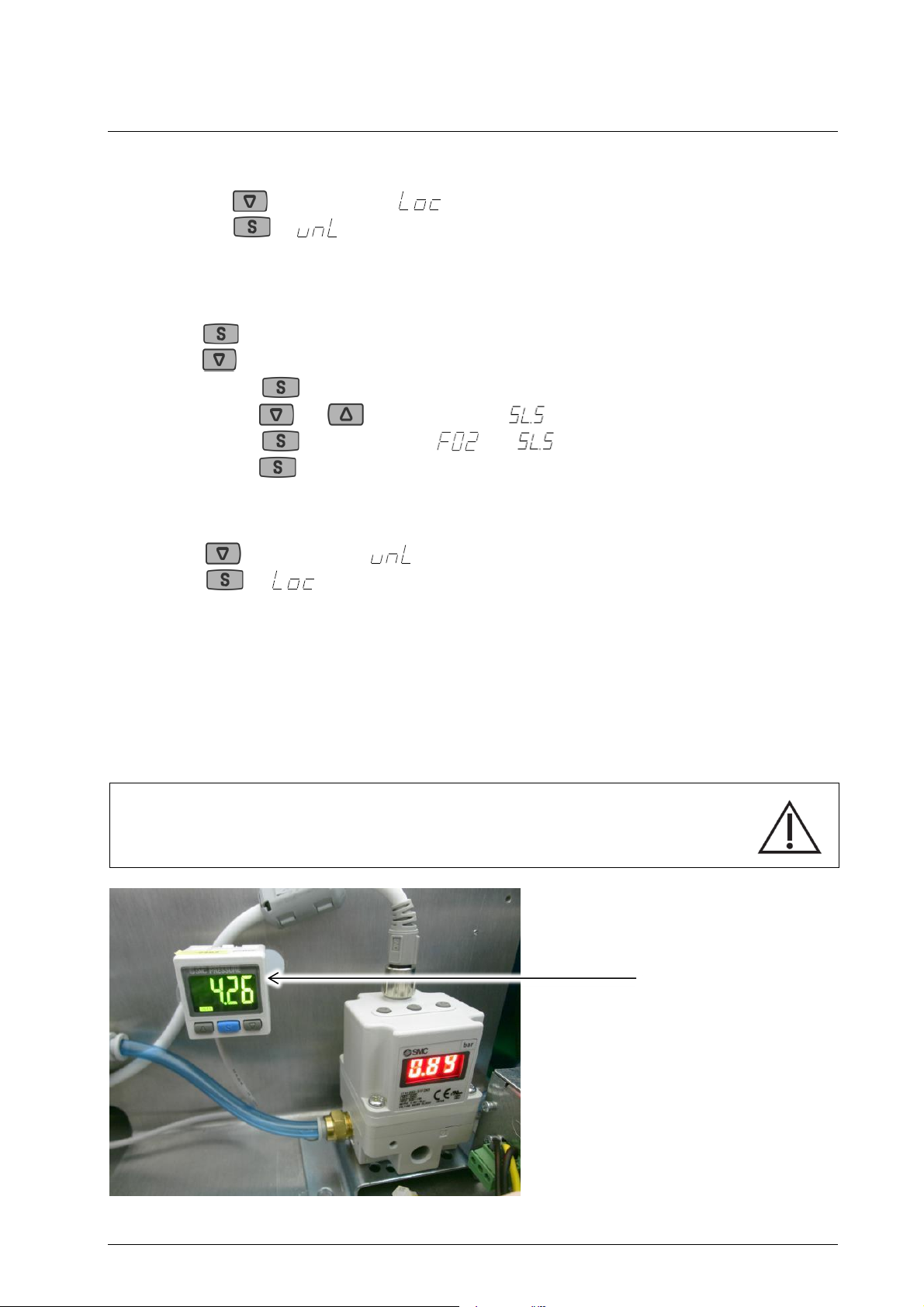

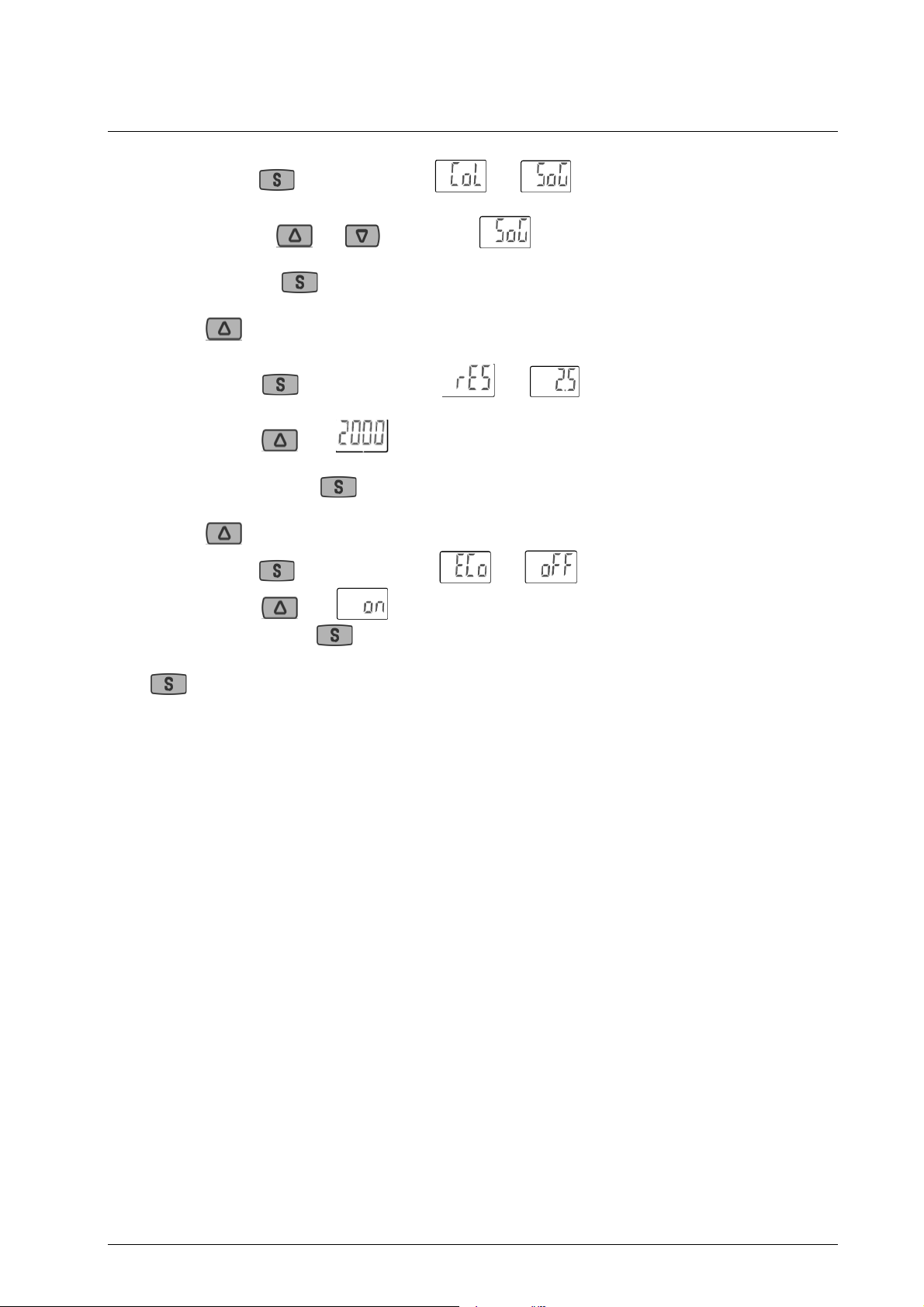

2.5.3 Pressure controller .............................................................................................. 8

3 CABINET TESTS ............................................................................................................................ 11

3.1 Check the Drawer Function ............................................................................................. 11

3.2 Check the Tube Connections ........................................................................................... 11

3.3 Check the air outlet of all nozzles (only model neo) ....................................................... 12

3.4 Check the o-rings of the nozzles...................................................................................... 12

3.5 Check the flow of the nozzles (only model neo and ENDODRY™) .................................. 13

3.6 Changing air circulation filter .......................................................................................... 14

3.7 Test function of the fan ................................................................................................... 15

3.8 Check the Door(s) ............................................................................................................ 15

3.9 Check Bar Code Reader ................................................................................................... 16

3.10Check Touch Display........................................................................................................ 16

4 OPERATING SOFTWARE .............................................................................................................. 17

4.1 License settings................................................................................................................ 17

4.2 Standard settings............................................................................................................. 17

4.3 Process settings ............................................................................................................... 18

4.4 Service settings................................................................................................................ 19

4.5 Software Update.............................................................................................................. 20

2 MAINTENANCE OF THE CONTROL DRAWER ................................................................................. 5

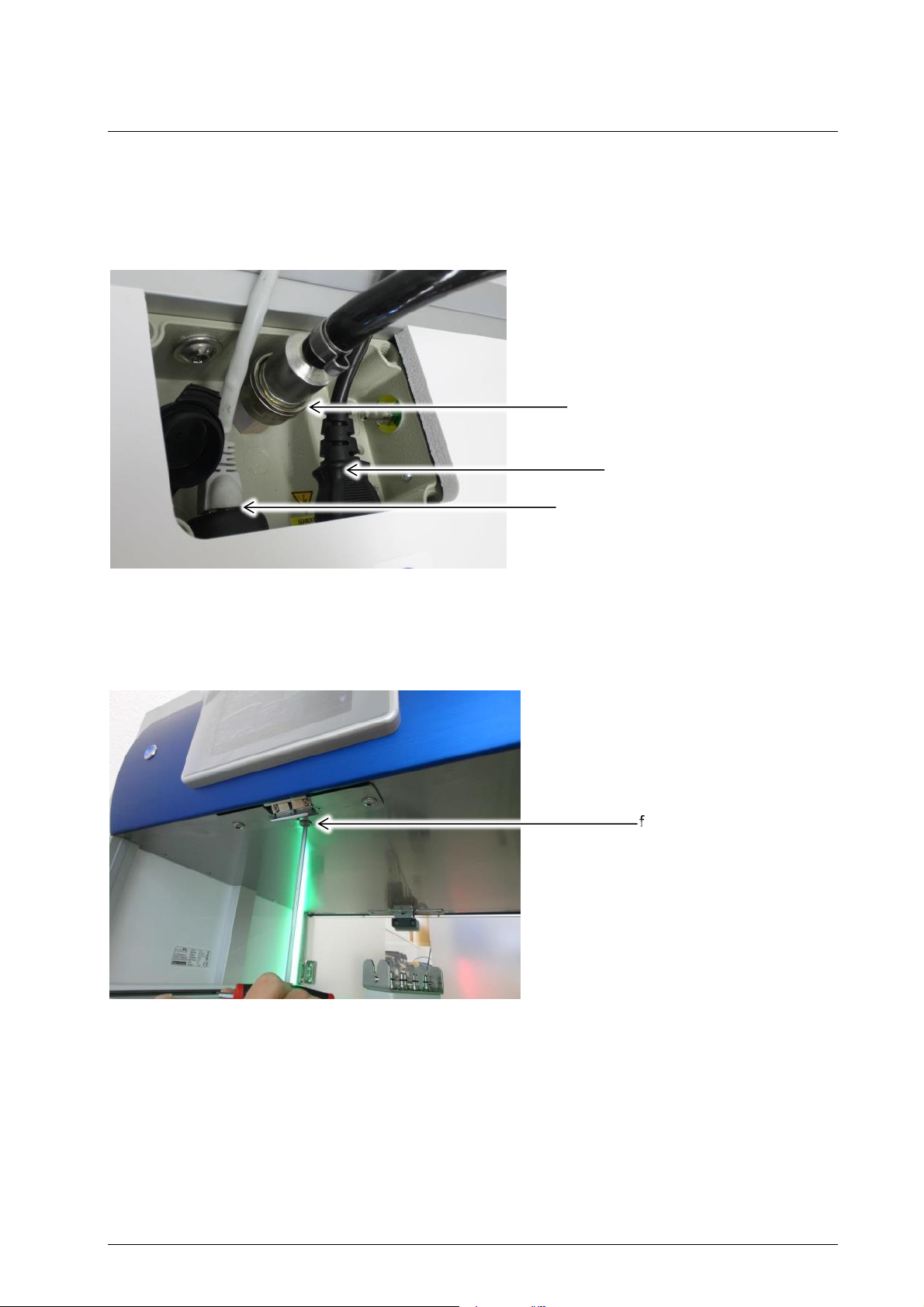

2.1 Accessible connections on the top of cabinet .............................................................. 5

2.2 Opening of the control system ....................................................................................... 5

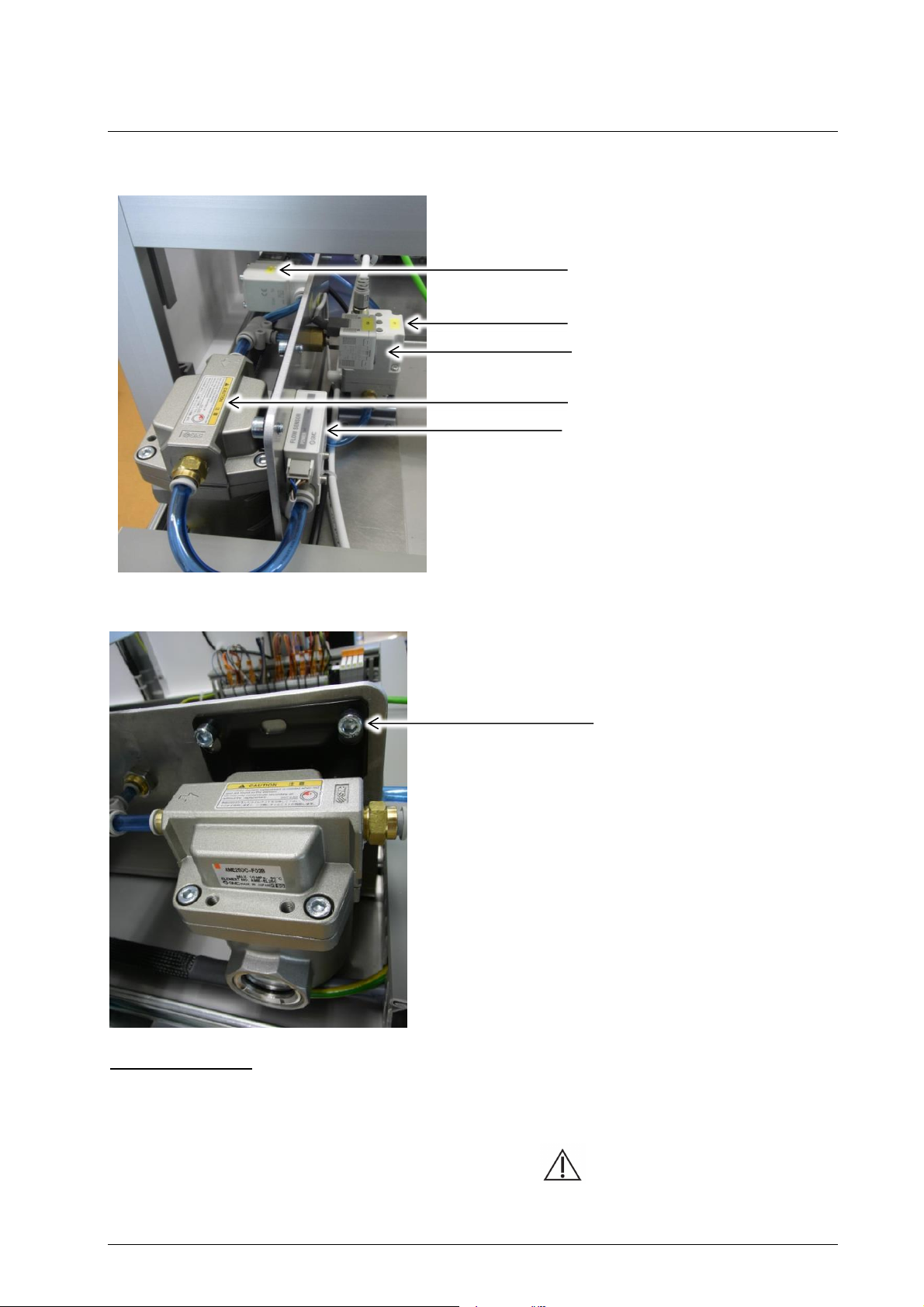

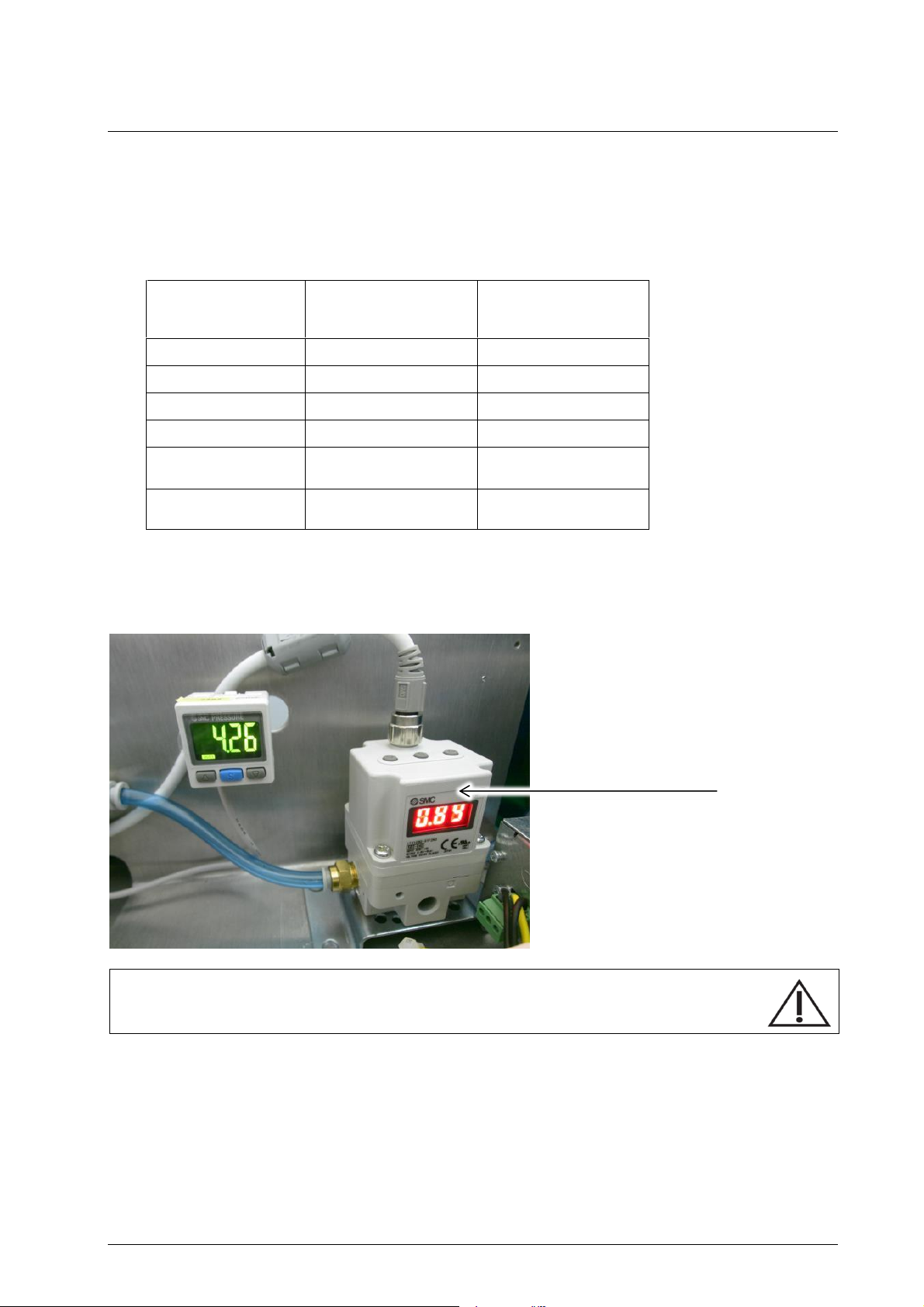

2.3 Construction of the Pneumatic Module

5 TECHNICAL DATA ........................................................................................................................ 25

6 CHECKLIST FOR MAINTENANCE OF THE CABINET...................................................................... 27

7 TECHNICAL SERVICE INFORMATION .......................................................................................... 28

ENDODRY™ and endoSTORE™are used interchangeably and are referred to as cabinet in this manual.

For service or service-related questions, contact Cantel Technical Supportoryour

local Cantel Distributor.