032-0204-EN Rev 4 -iii

Chapter 1 - Preinstallation

General Information ............................................................................................ 1-1

Certified Component ...................................................................................................1-1

Environmental Factors ................................................................................................1-1

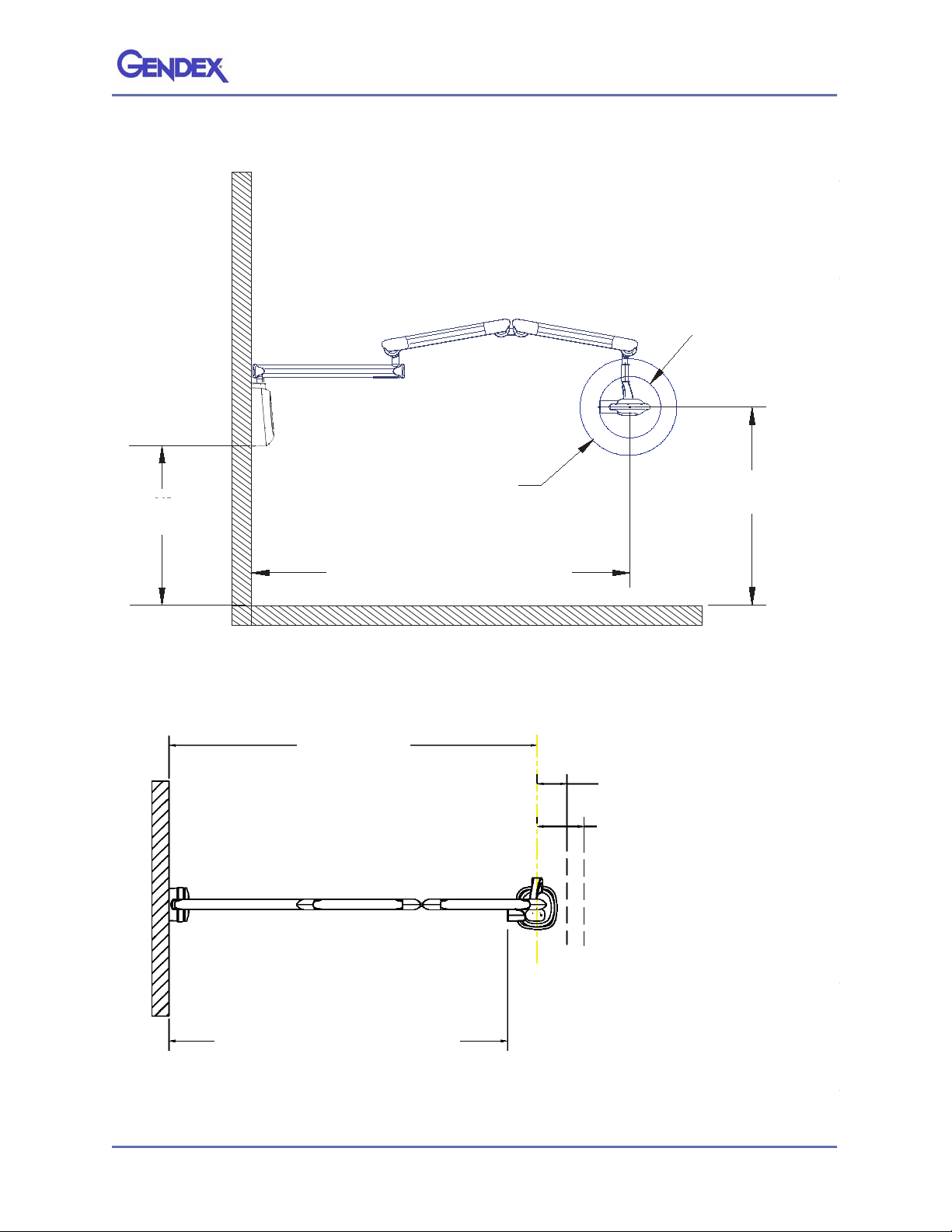

Reach and Coverage ...................................................................................................1-1

Electrical Power Requirements ....................................................................................1-6

Wall Support Considerations ......................................................................................1-7

Additional Kits Available .............................................................................................1-8

Chapter 2 - Installation

Install Master Control Touch Panel ...................................................................... 2-1

Install Master Control .......................................................................................... 2-4

Mount to Single Wood Wall Stud .................................................................................2-5

Mount to Wood Wall Studs (16-inch Center) ................................................................2-6

Mount to a Solid Wall ..................................................................................................2-8

Mount in a Pass-through Box or Cabinet System .........................................................2-9

Mount to Wall with Steel Studs .................................................................................2-10

Final Steps to Install Master Control .................................................................. 2-11

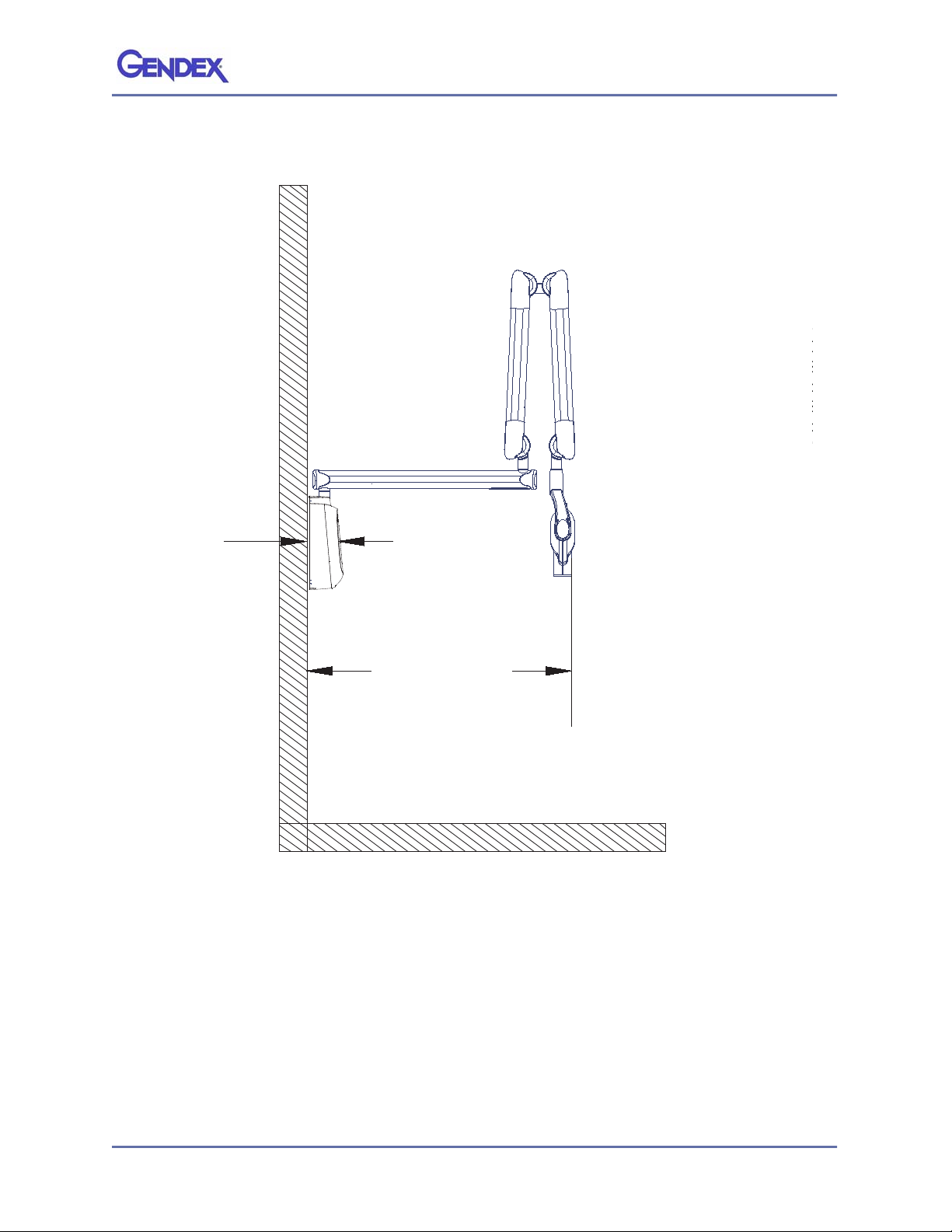

Install Horizontal Arm ....................................................................................... 2-12

Install Articulated Arm & Tubehead Assembly ................................................... 2-15

Connect Cabling and Wires ................................................................................ 2-18

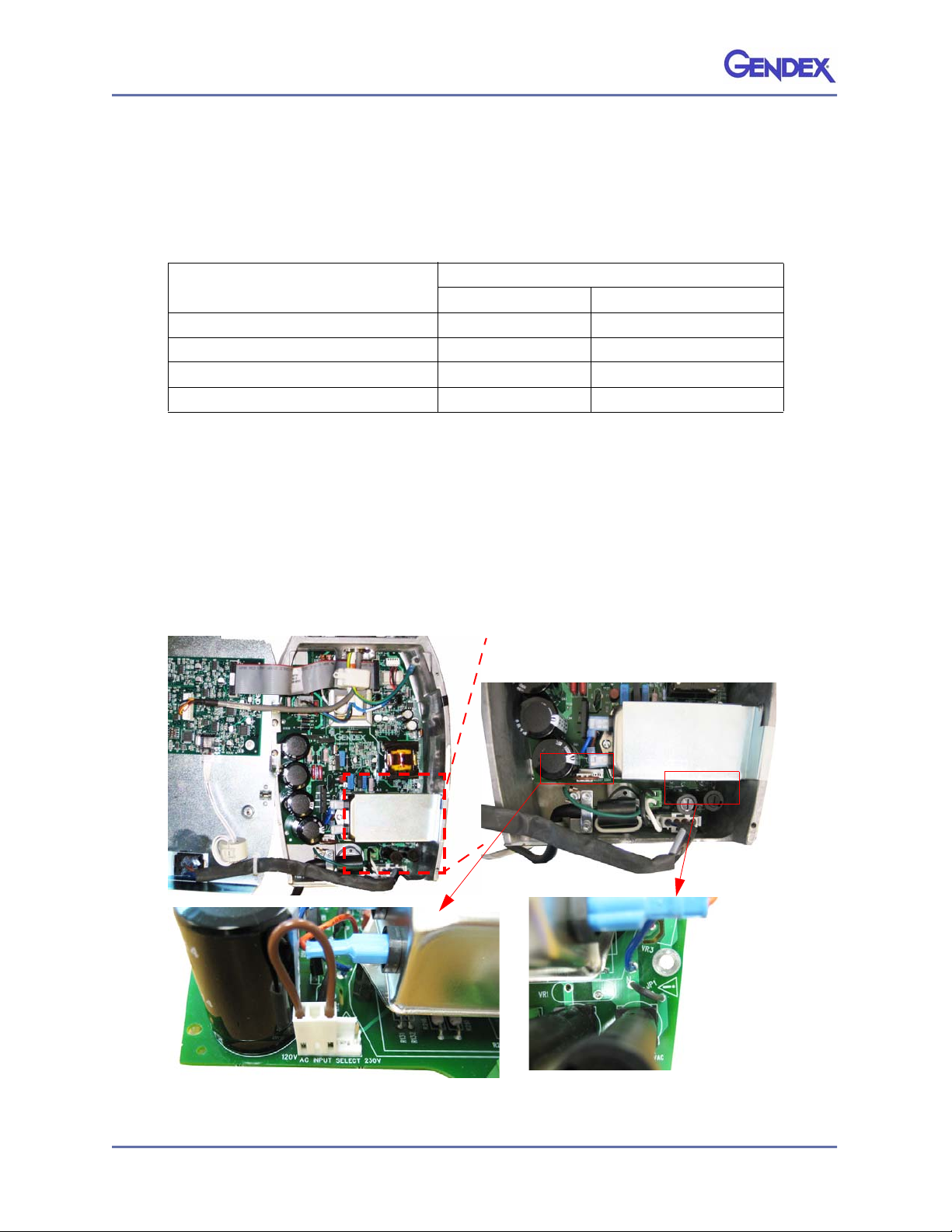

Electrical Power Connection .............................................................................. 2-23

Complete the Installation .................................................................................. 2-26

Local Touch Panel .....................................................................................................2-26

Remote Touch Panel .................................................................................................2-28

Articulated Arm Vertical Drift Adjustment .......................................................... 2-30

Chapter 3 - System Checks

Electrical Calibration Checks ............................................................................... 3-1

Configure Exposure Settings ............................................................................... 3-2

Final System Checks ........................................................................................... 3-3

Table of Contents