CAPINTEC, INC. CRC®-712MX

TABLE OF CONTENTS

PREFACE

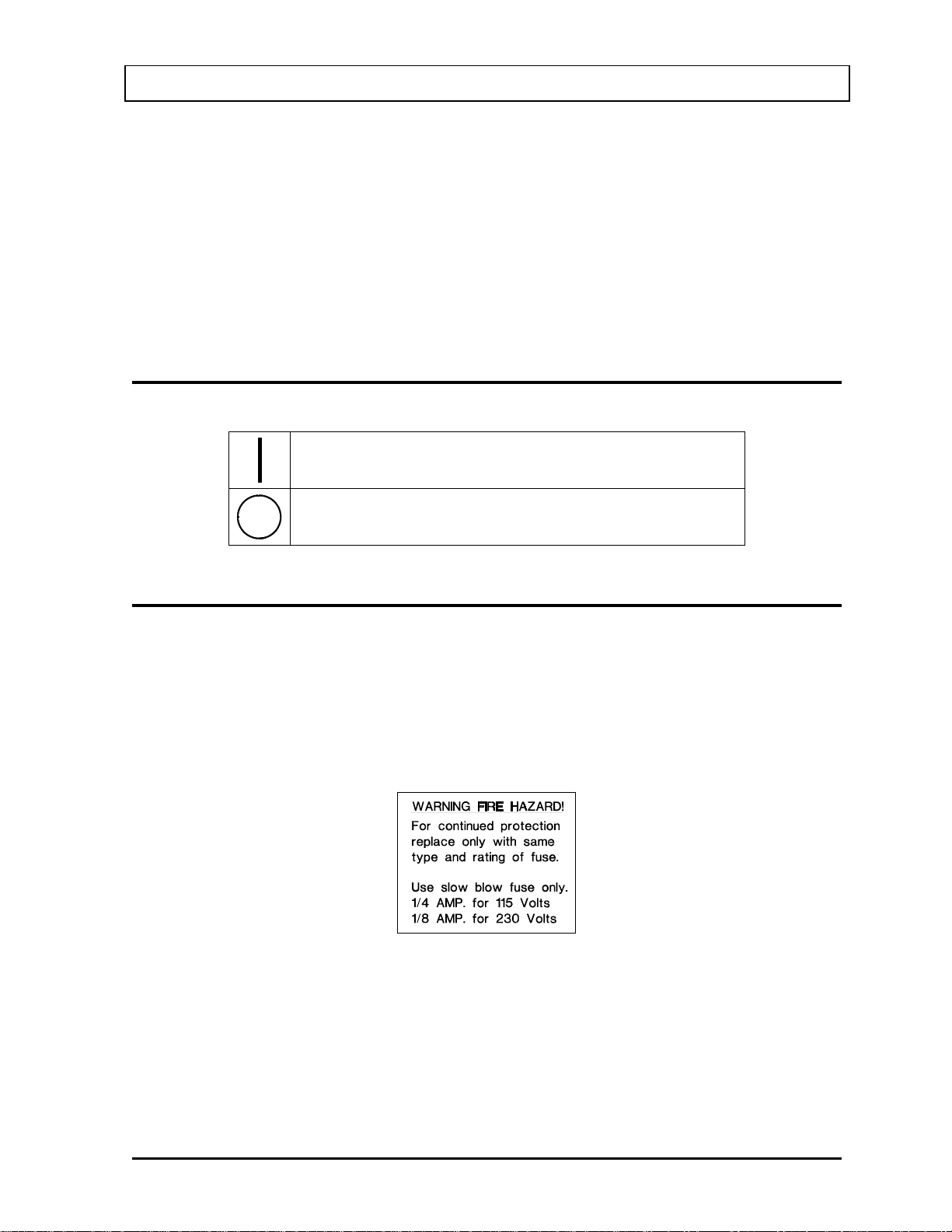

SAFETY................................................................................................................................1-1

SYMBOL DEFINITIONS....................................................................................................1-1

WARNING AND CAUTION LABELS.................................................................................1-1

CAUTIONS AND NOTES ..................................................................................................1-3

GENERAL SAFETY TIPS..................................................................................................1-4

FUNCTIONAL & TECHNICAL DESCRIPTION....................................................................2-1

FUNCTIONAL DESCRIPTION ..........................................................................................2-1

FEATURES........................................................................................................................2-1

TECHNICAL DESCRIPTION.............................................................................................2-3

Warm Up Period.............................................................................................................2-3

Environment Requirements............................................................................................2-3

Power Requirements......................................................................................................2-3

Dimensions ....................................................................................................................2-4

Performance ..................................................................................................................2-5

GENERAL OPERATING INSTRUCTIONS ..........................................................................3-1

GENERAL..........................................................................................................................3-1

PANEL DESCRIPTIONS...................................................................................................3-1

Front Panel ....................................................................................................................3-1

Back Panel.....................................................................................................................3-4

SYSTEM SETUP...................................................................................................................4-1

GENERAL..........................................................................................................................4-1

RECEIVING CONDITION EXAMINATION........................................................................4-1

UNPACKING AND INSTALLATION..................................................................................4-1

ASSEMBLY .......................................................................................................................4-2

ENVIRONMENT REQUIREMENTS ..................................................................................4-3

POWER REQUIREMENTS ...............................................................................................4-3

Readout .........................................................................................................................4-3

Printers...........................................................................................................................4-3

INITIAL TURN ON PROCEDURES...................................................................................4-4

ACCEPTANCE TESTING..................................................................................................4-4

GENERAL OPERATIONAL SETUP..................................................................................4-5

Locking the Curie or Becquerel Mode of Operation.......................................................4-5

Reassignment of a Preset Push-Button.........................................................................4-6

QUALITY ASSURANCE & ACCEPTANCE TESTING.........................................................5-1

GENERAL..........................................................................................................................5-1

ACCEPTANCE TESTING..................................................................................................5-1

Geometry Test ...............................................................................................................5-1

January 08 TABLE OF CONTENTS TOC-1