For today’s performance

kitchens with CapKold cook-

chill production systems,Avtec

offers ventilation and utility

distribution systems (UDS)

to satisfy your customization

requirements. Avtec’s high

quality, reliable ventilation hoods

handle the CapKold cooking and heating parts of your cook-chill

operation. Avtec UDS provides

single point connections for each

utility, ease of installation and

maintenance, and permits future

line-up changes in your cook-

chill kitchen. Look to Avtec to

complement your CapKold cook-

chill kitchen operation.

Avtec

®

Chinook Hood

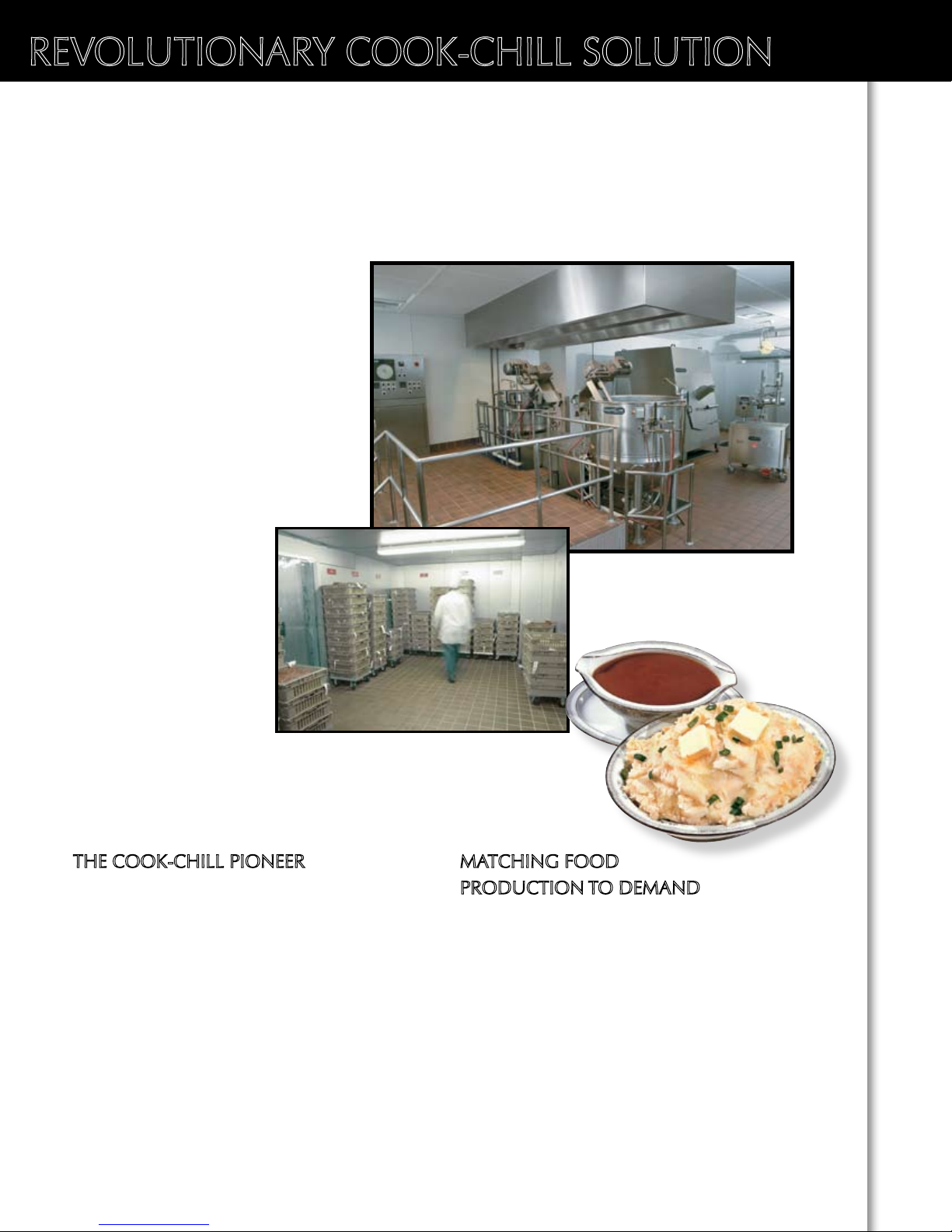

REFRIGERATED STORAGE (FOOD BANK)

Prepared foods are stored in walk-in refrigerators

(commonly referred to as a Food Bank). Temperature is maintained

just above the freezing point, to preserve the freshness, texture,

color and quality of the food. Menu items are pulled from inventory

as needed, used on site, or shipped to remote serving points.

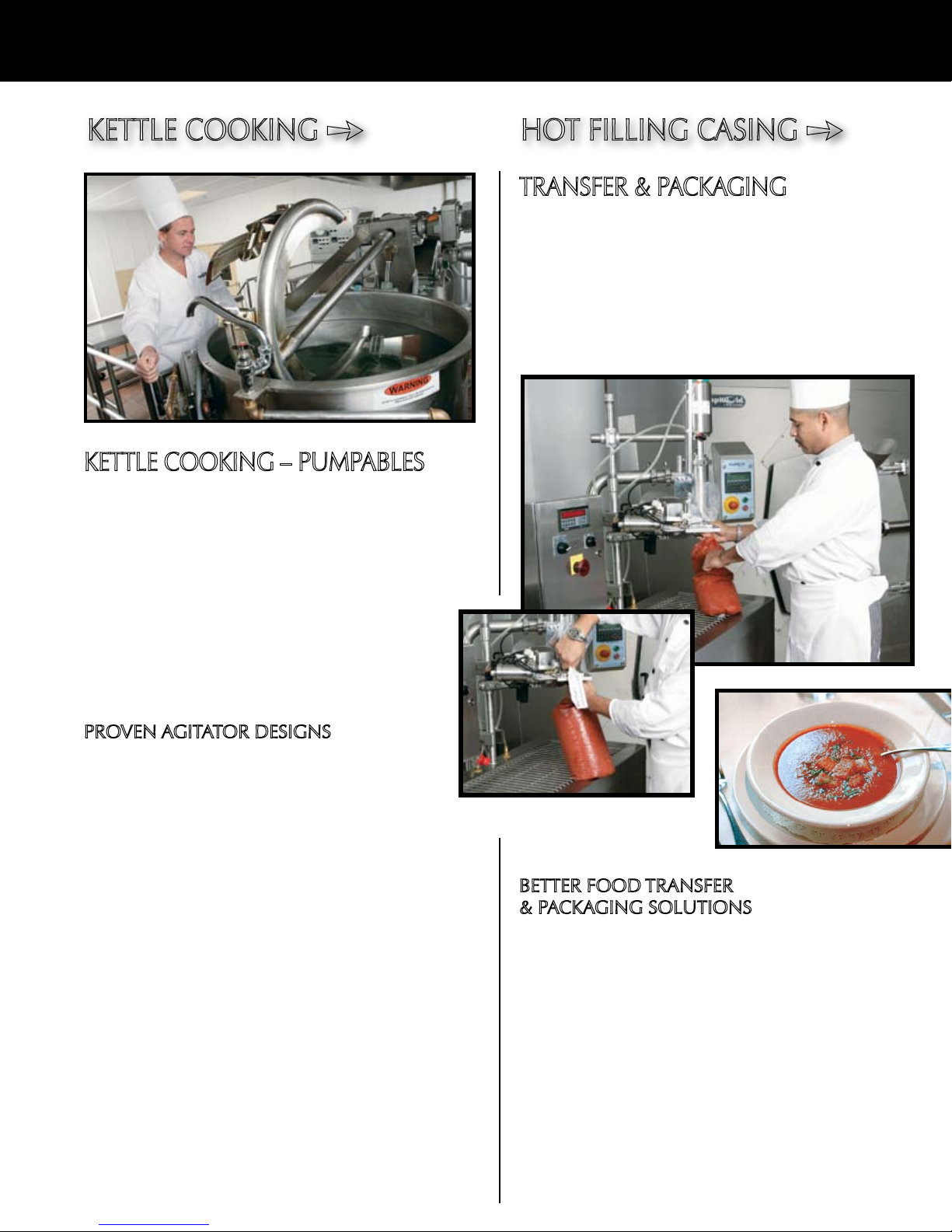

HEATING & SERVING

CapKold items can be quickly heated to safe serving

temperatures right in the casing, placed in steam table pans, or

individually portioned. Groen offers a line of steam equipment that

is perfect for rethermalizing food.

CapKold foods are ideal for pre-plating as part of a tray

makeup and delivery system. They can be used in combination

with freshly prepared foods and foods which have been blast-

chilled. Randell offers a line of blast chillers as well as standard and

customized hot and cold food tables for serving applications.

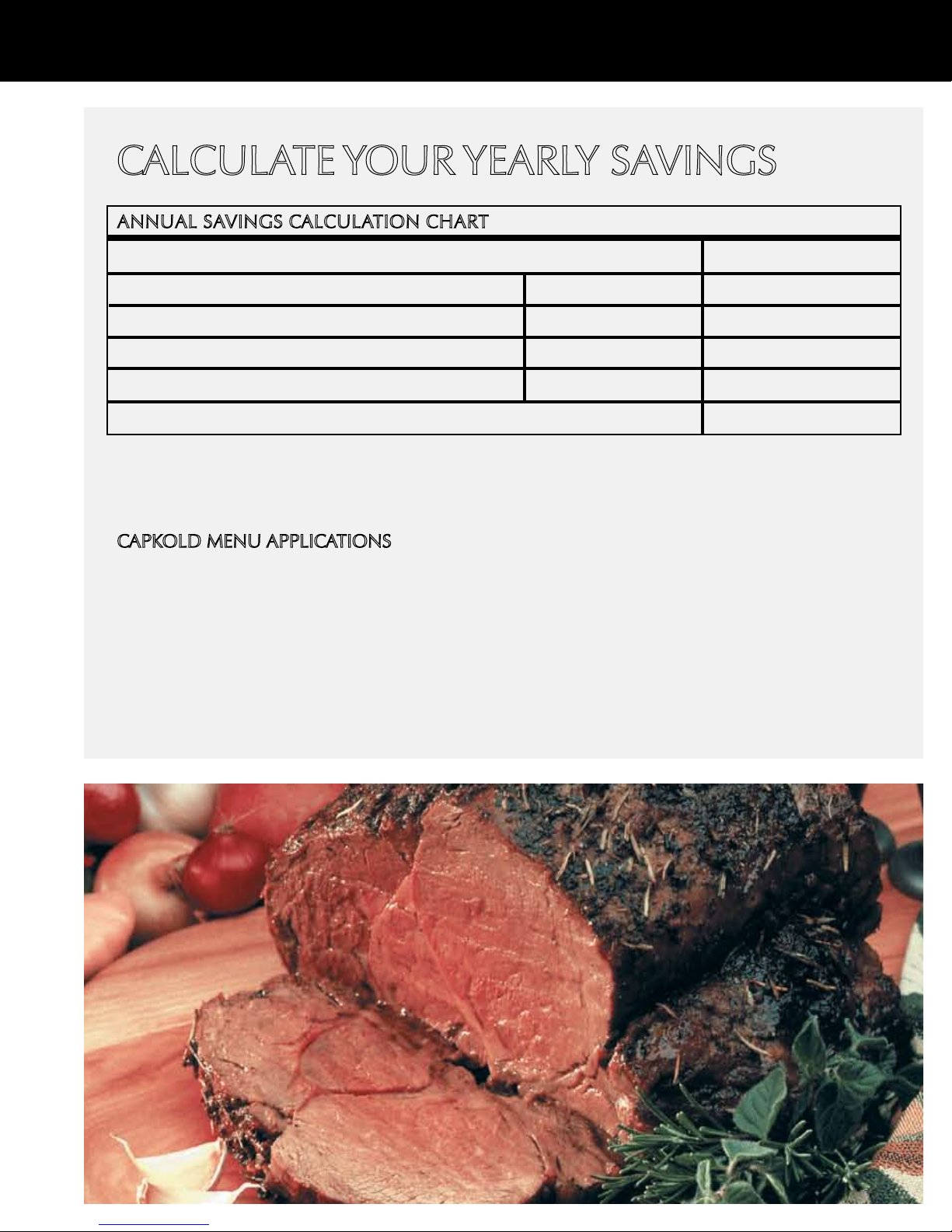

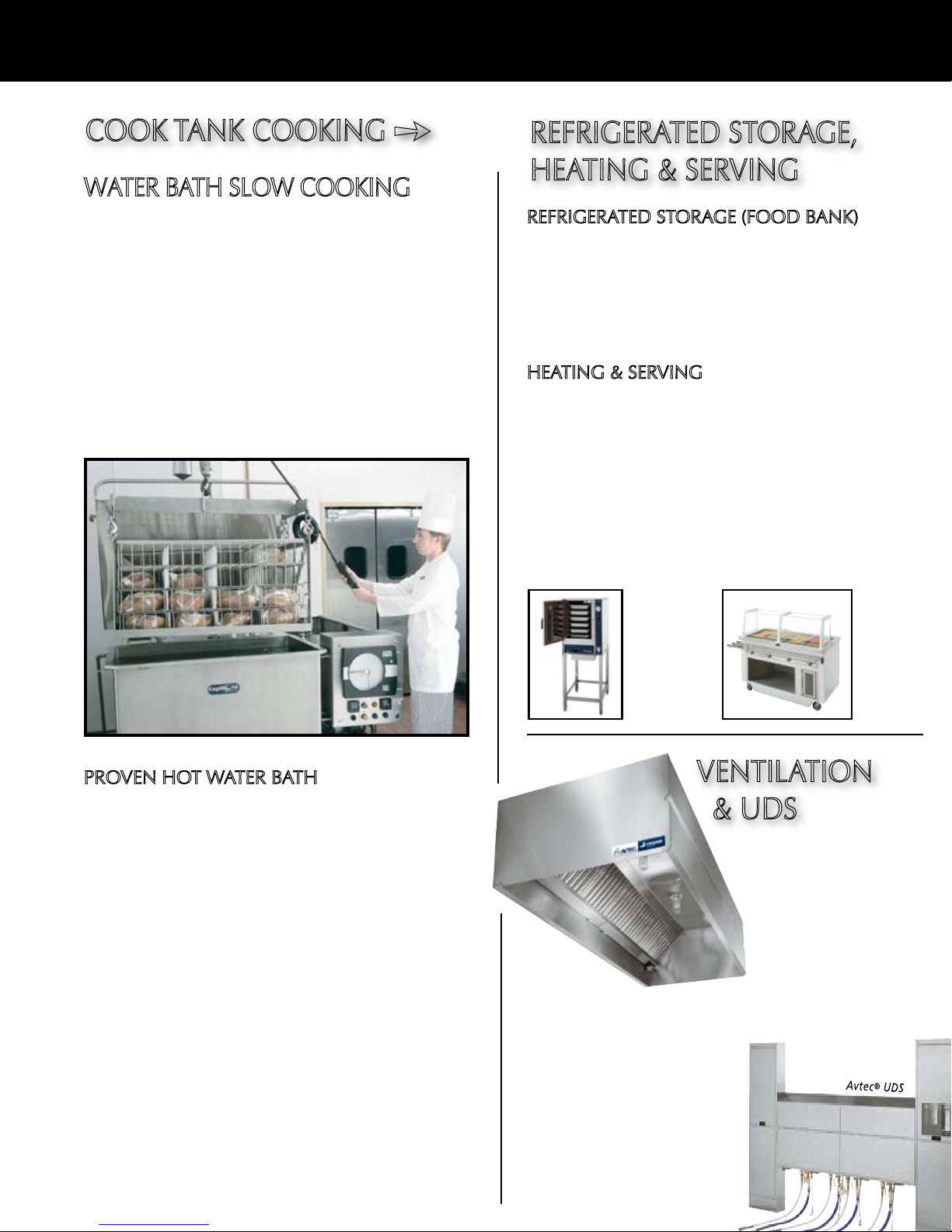

WATER BATH SLOW COOKING

Whole-meat products, such as roasts and turkey breasts,

and many prepared foods such as rice, vegetables and meatloaf,

can be slow-cooked in a WaterJet or a Cook Tank. Both use

circulating hot water to cook products, vacuum packaged in plastic

casings. At the end of the cooking cycle, the units automatically

drain and then circulate cold water for rapid chilling, without the

product ever leaving the tank.

Water bath slow cooking can be done overnight,

unattended. An integral control system monitors both cooking

and chilling and provides a time/temperature production record

for HACCP and quality assurance.

PROVEN HOT WATER BATH

CapKold pioneered hot water bath, low temperature

cooking of meats and prepared foods in vacuum-sealed plastic

casings. CapKold Cook Tanks are capable of preparing hundreds

of pounds of perfect rare roast beef and more.

• CapKold Cook Tanks are available with 500-, 1000- and

2000-pound nominal.

• Dual purpose Tumble Chiller/Cook Tanks and WaterJets

are designed for smaller operators and kitchens.

• A powerful water circulation pump provides uniform

cooking and cooling.

• A baffled bottom steam jacket provides fast and

efficient heating with direct steam.

• Integrated control systems allow overnight,

unattended cooking, cooling and documentation.

COOK TANK COOKING ➙REFRIGERATED STORAGE,

HEATING & SERVING

Loading and unloading food product with a push of a button

VENTILATION

& UDS

Groen steamers

are an excellent

way to reheat

food in casings

or steam pans

Randell RanServe

hot food tables

have integral

heaters and are

NSF listed

COOK-CHILL PRODUCTION SYSTEMS AT A GLANCE