Capricorn CEP 2000 User manual

OPERATING INSTRUCTIONS FOR THE

CAPRICORN BENCH TOP CENTRIFUGE

MODEL NO. CEP 2000

FOR OTHER LANGUAGES, PLEASE VISIT OUR WEBSITE

CES INSTRUCTIONS SONT PRÉSENTES DANS D'AUTRES

LANGUES SUR NOTRE EMPLACEMENT DE WEB

DIESE ANWEISUNGEN SIND IN ANDEREN SPRACHEN IN

UNSERER WEB SITE VORHANDEN

ESTAS INSTRUCCIONES ESTÁN PRESENTES EN OTRAS

IDIOMAS EN NUESTRO WEB SITE

www.capricorn-labs.co.uk

30 0

1218

24 6

15

921

27 3

WARNING

THIS EQUIPMENT

MUST BE EARTHED

FUSE

Knurled

Nut

Observation

Window

Speed

Control

Knob

IEC

Power Inlet

Catch

Neon Indicators

Timer

Knob

CAPRICORN BENCH TOP CENTRIFUGE

MODEL NO. CEP 2000

SETTING UP PAGE 1

LOADING PAGE 1

STARTING PAGE 2

COMPLETION PAGE 3

BREAKAGES PAGE 3

TECHNICAL SPECIFICATIONS PAGE 4

English

OPERATING INSTRUCTIONS FOR THE

CAPRICORN BENCH TOP CENTRIFUGE

MODEL NO. CEP 2000

SETTING UP

WARNING - THIS EQUIPMENT MUST BE EARTHED

1. Insert the mains lead into the IEC power inlet at the rear of the unit.

2. Plug the unit into a grounded power socket - DO NOT SWITCH ON

(OFF is indicated by ‘0’, ON is indicated by ‘1’).

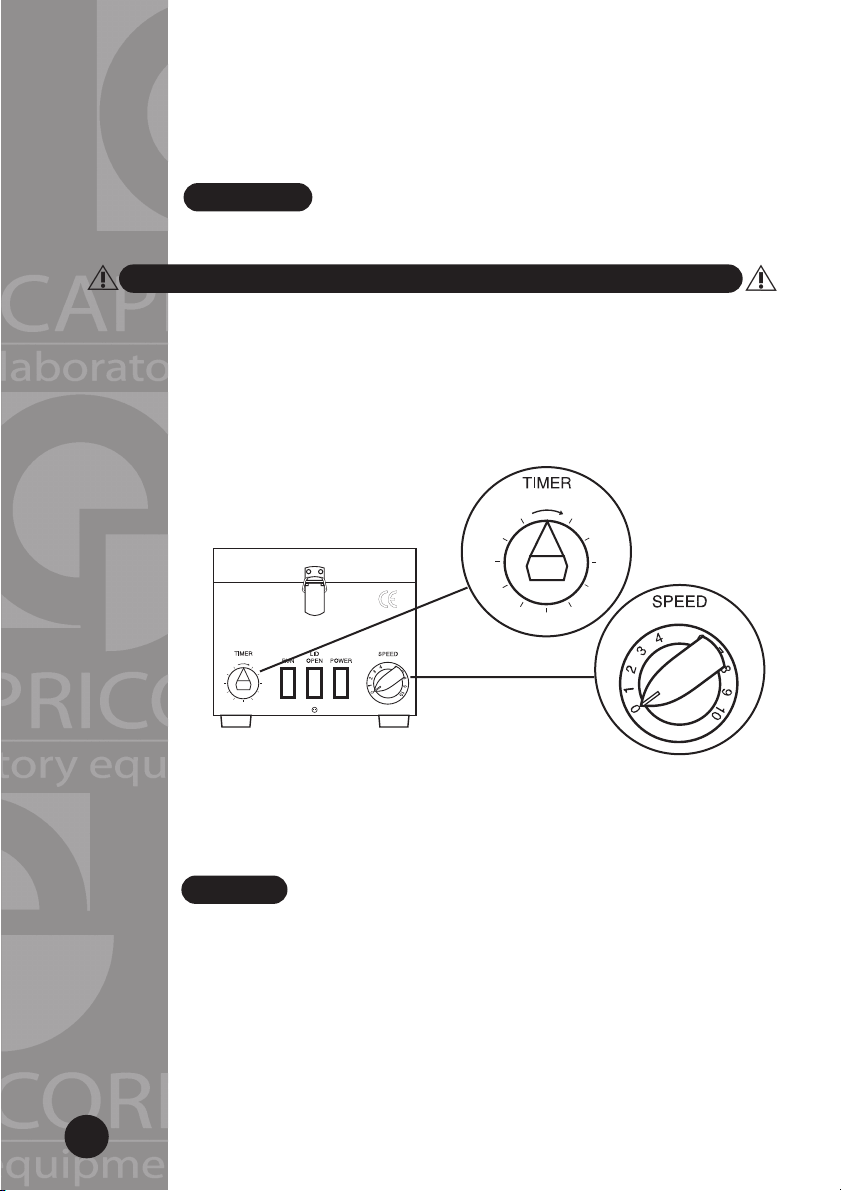

3. Ensure that the TIMER is in the OFF position, signified by the pointer

being in a vertical position, and that the SPEED control knob is set to ‘0’

(see Figure1).

4. Switch the power on at the rear of the unit. At this point the green ‘POWER’

neon indicator will come on and, after a short delay, the amber ‘LID OPEN’

neon indicator will also come on, indicating that the lid may be opened.

LOADING

1. Open the lid by undoing the catch on the front of the unit and lifting the lid.

2. Place the sample tubes in the rotor, ensuring that:

(a) The correct tubes are inserted into their corresponding places in the rotor,

if the rotor accommodates more than one size of tube.

(b) The rotor is loaded symmetrically, using tubes of equal size with contents

of equal weight. If you are unable to balance the rotor, due to an odd number

of tubes, fill an empty tube with water and use this as a balance. This water

filled tube can, if necessary, be used continually for this purpose.

(see Figure 2).

5

30 0

1218

24 6

15

921

27 3

30 0

1218

24 6

15

921

27 3

5

(Figure 1)

1

(Figure 2)

WARNING - DO NOT RUN THE CENTRIFUGE

OUT OF BALANCE!

3. Once the rotor is loaded, close the lid and secure the catch

WARNING - ALWAYS ENSURE THAT THE POWER IS ON

WHEN ATTEMPTING TO CLOSE THE LID

STARTING

1. Turn the “SPEED” control knob to the desired setting:-

SPEEDS AT ROTOR HEAD

SETTING R.P.M. RCF x g

01750 300

12000 400

22500 500

33350 1000

44000 1600

54700 2200

65250 2750

75850 3500

86300 4000

96700 4500

10 7000 5000

2. Turn the ‘TIMER’ knob in a clockwise direction to the required run time.

At this point the amber ‘LID OPEN’ neon indicator will go out, the red ‘RUN’

neon indicator will come on and the rotor will start to rotate.

PLEASE NOTE: if the required run time is less than 10 minutes,

turn the ‘TIMER’ knob up to 15 minutes or more and then back to

the desired setting. This will ensure that the timing is accurate.

✓✓✘

2

(Timer set to 15mins).

THE ABOVE FIGURES ARE APPROXIMATE AND INTENDED FOR GUIDANCE PURPOSES ONLY.

3. The centrifuge is now locked and it will not be possible to open the lid until the

rotor has stopped and the amber ‘LID OPEN’ neon indicator has come on.

4. The centrifuge may be subject to some vibration initially, while the rotor accelerates

through a critical stage, but this should cease once it has reached a reasonable

speed. However. if the vibration continues, it is most likely that the centrifuge is

unbalanced. If this is the case, the ‘TIMER’ knob must be turned OFF and the

rotor will slow down and come to a stop. Once the amber ‘LID OPEN’ neon

indicator has come on, the lid should be opened and the balance checked.

COMPLETION

1. Once the run has been completed, the timer will switch off and the rotor will

start to decelerate. The red ‘RUN’ neon indicator will go out and the green

‘POWER’ neon indicator will remain on. Once the rotor has stopped, the

amber ‘LID OPEN’ neon indicator will come on, after a short delay, indicating

that the lid may be opened.

2. Remove the sample tubes and close the lid, securing the catch on the front of the

unit. Once the lid has been closed, the power should be turned off at the rear of

the unit.

WARNING - ALWAYS ENSURE THAT THE POWER IS

ON WHEN ATTEMPTING TO CLOSE THE LID

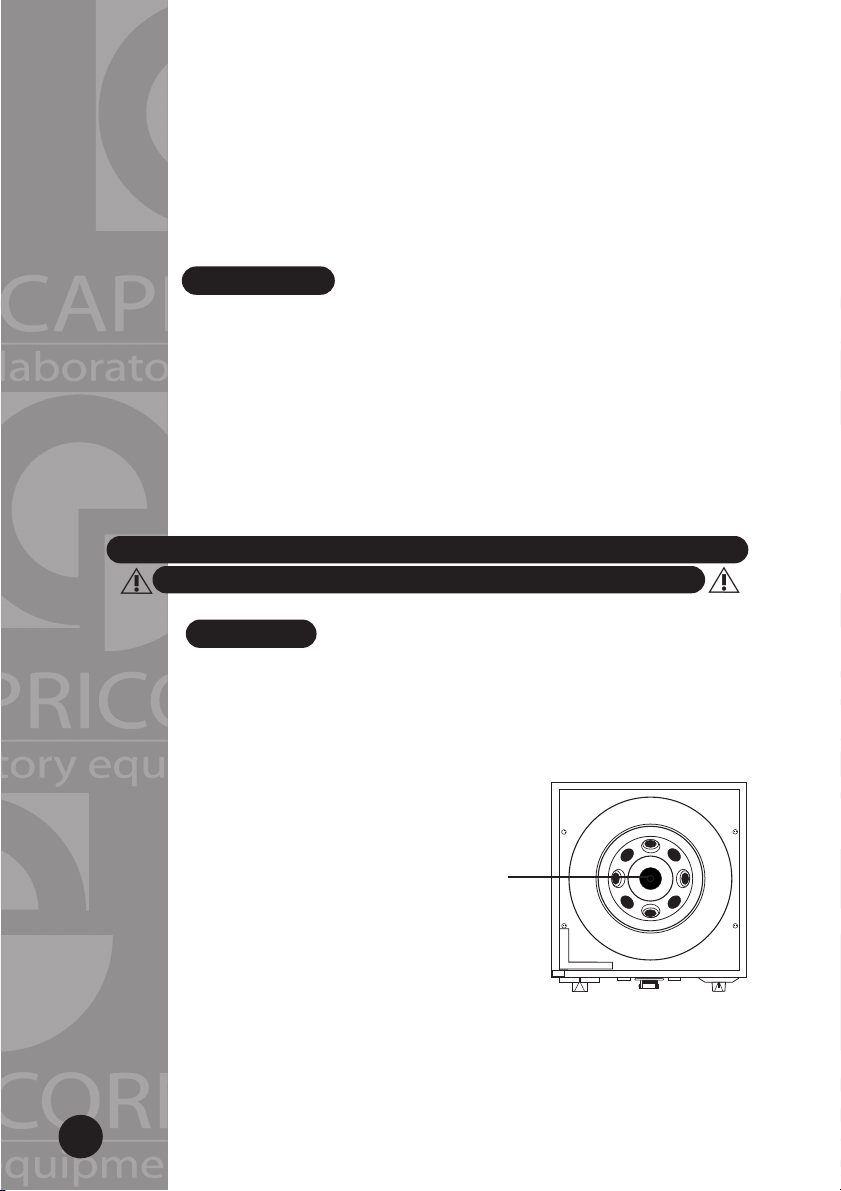

BREAKAGES

1. In the event of tube breakage,the ‘TIMER’ should be turned OFF, by turning it

in an anti-clockwise direction back to the vertical position. Once the amber ‘LID

OPEN’ neon indicator has come on, the lid should be opened and the rotor

should be removed by unscrewing the knurled nut that secures it to the unit (see

figure 3). The rotor should then be thoroughly cleaned and washed, being careful

not to allow any broken glass to cause injury.

2. After any breakages, the rotor must be completely free of any glass fragments or

other materials. If this is not the case, it will not be possible to successfully balance

the rotor on future operations.

3. Once the rotor has been successfully cleaned and the imbalance rectified, the

centrifuge may be re-loaded with samples and operated in line with the procedures

set out in the preceding sections.

(Figure 3)

Knurled

nut

3

In the event of any operational or technical problems,

please contact Capricorn Laboratory Equipment on

+44 (0)1425 65 00 88 and ask for Technical Support

TECHNICAL SPECIFICATION

Model No: CEP 2000

Motor: AC Series 1/15 HP

Max RCF: 4000g

Max Speed : 6000 rpm

Power Requirements: 220-240 VAC 50Hz, 3A Fused Supply (UK)

IEC Inlet 1.6A Quick Blow Fuse

WARNING

THIS EQUIPMENT

MUST BE EARTHED

FUSE

FUSE

(Figure 4)

4

DECLARATION OF CONFORMITY

Manufacturers Name: Capricorn Laboratory Equipment

Manufacturers Address: Glasshouse Studios, Fryern Court Road,Fordingbridge, Hants, SP6 1NG

Declares that the product:

Product Name: Bench Top Centrifuge

Model Number: CEP 2000

Conforms to the following Product Specifications:

EMC: EN61326-1 : 1997 Emissions & Immunity

EN55022 : 1998 Class B

EN61000-3-2 : 1995 Class A

EN61000-3-3 : 1995

Supplementary Information:

The product herewith complies with the requirements of the EMC Directive 89/336/EEC and carries

the CE marking accordingly. The product was tested in a typical configuration. This declaration only applies

to those centrifuges manufactured after the date shown below.

Fordingbridge, Hants. U.K. 01 November 2005

D J Prevett

Technical Manager

For sales or technical support, please contact Capricorn Laboratory Equipment:

Telephone: +44 (0)1425 65 00 88 Fax: +44 (0)1425 65 00 92

e-mail: [email protected]

EN61000-4-2 : 1995

EN61000-4-3 : 1995

EN61000-4-4 : 1995

EN61000-4-5 : 1995

EN61000-4-6 : 1993

EN61000-4-11 : 1994

Glasshouse Studios ●Fr yern Court Road

Fordingbridge ●Hants ●SP6 1NG ●UK

Tel: +44 (0)1425 65 00 88 ●Fax: +44 (0)1425 65 00 92

or 0700 CAPRICORN (0700 2277426)

Table of contents

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

VWR

VWR SAS Super IAQ instruction manual

illumina

illumina MiSeqDx reference guide