are the MINIMUM required for assembly.

several spares and I typically include extras of the majority of the items.

To assemble this blaster you will need a Slotted Screwdriver, Small Philips Screwdriver, 3/8 Combination Wrench, and a

Round Needle File. You may also need a 3/8” socket and a square drive extension to use with it.

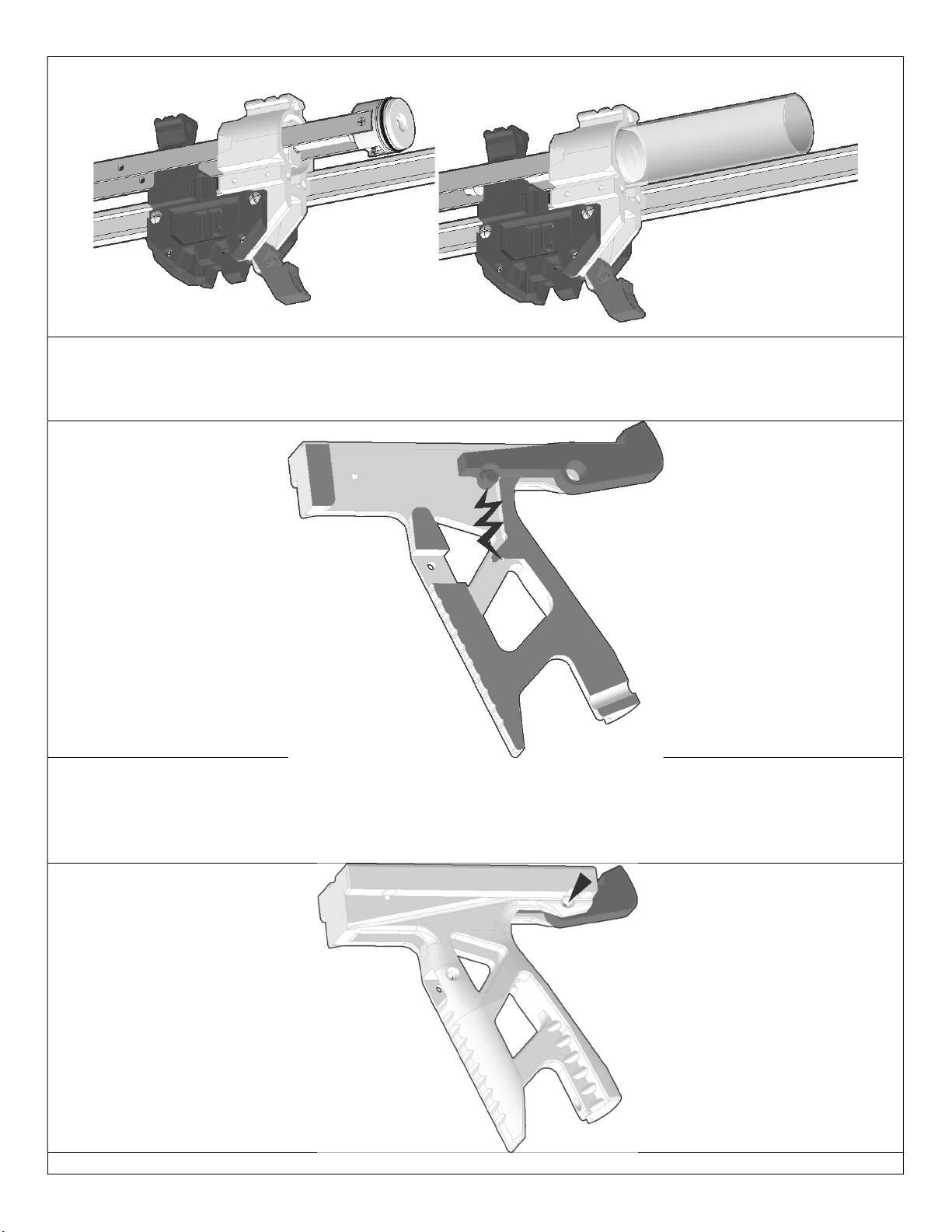

The Plunger Tube in the Hardware Kit does come pre-lubricated. But it's also a good idea to have extra lubricant on-hand

for the Plunger Tube and I would recommend only using a clear Silicone Grease such as Oatey's brand #30219. Any clear

90% silicone grease will work fine so long as it does not include any additives. NEVER USE SILICONE LUBRICANT FROM

AN AEROSOL CAN. The propellants used in those are harmful to plastic parts.

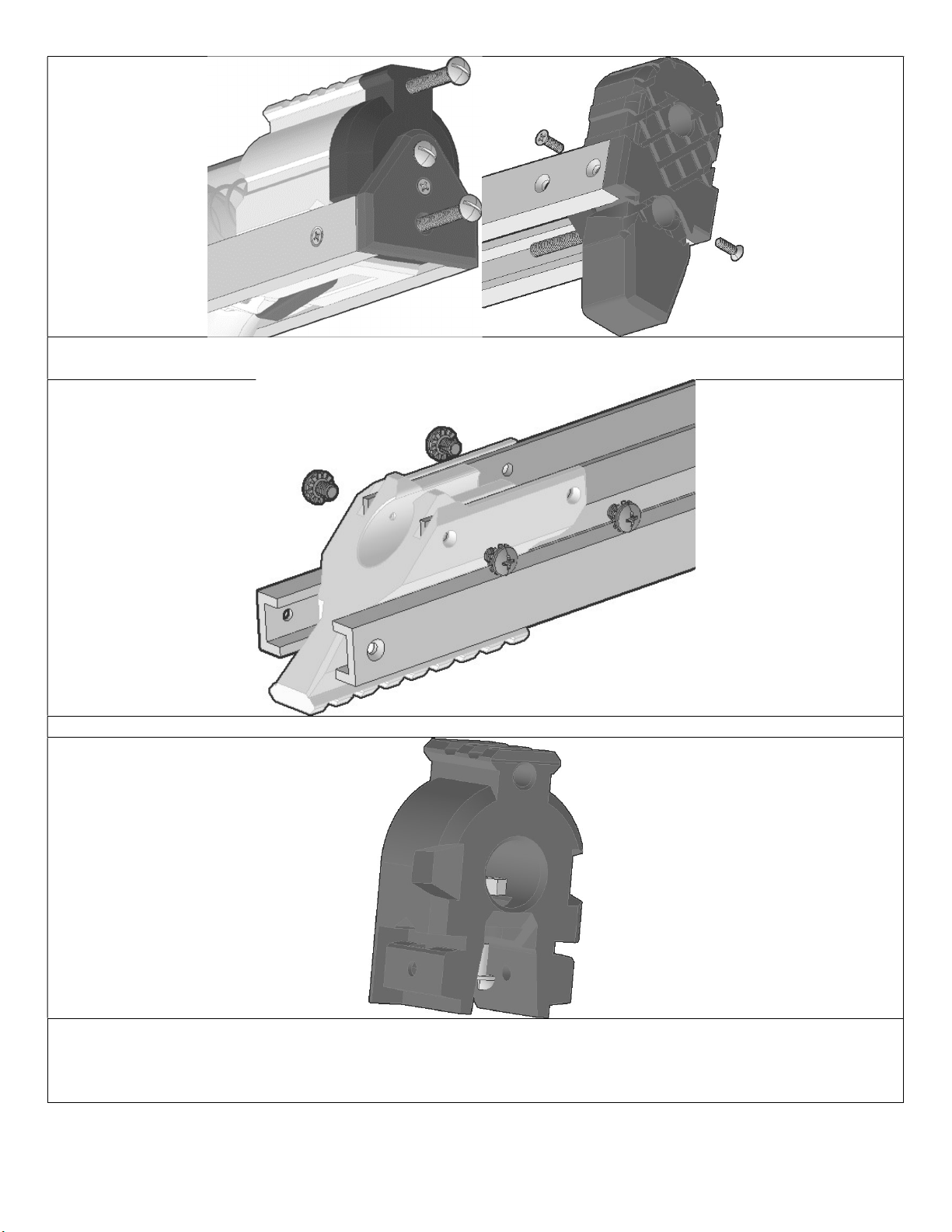

ALSO AVOID DRY-FIRING THIS BLASTER EXCESSIVELY. Firing without a dart in the barrel will add unneeded wear on this

blaster, especially if the higher load rating springs are installed. Also do not pull the trigger with the foregrip in the

rearward position (with the breech open). The breech being slammed closed by the main spring is very likely to damage

both the breech itself and the magwell.