3

Table of Contents

WARRANTY ............................................................................................................................................................................. 4

INSTALLATION ........................................................................................................................................................................ 5

Mechanical ........................................................................................................................................................................... 5

Curb and Ductwork ............................................................................................................................................................... 7

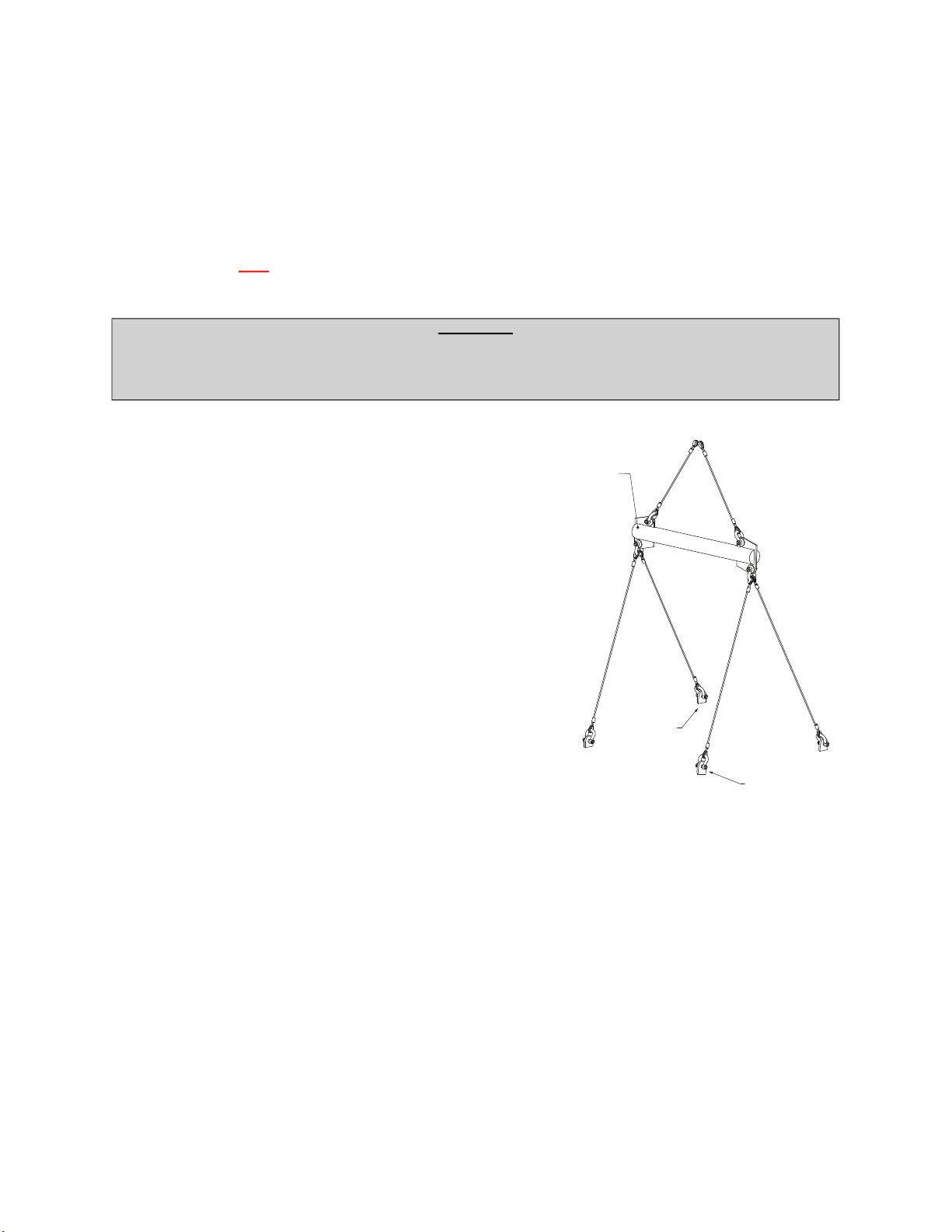

Roof Mount Installation ......................................................................................................................................................... 8

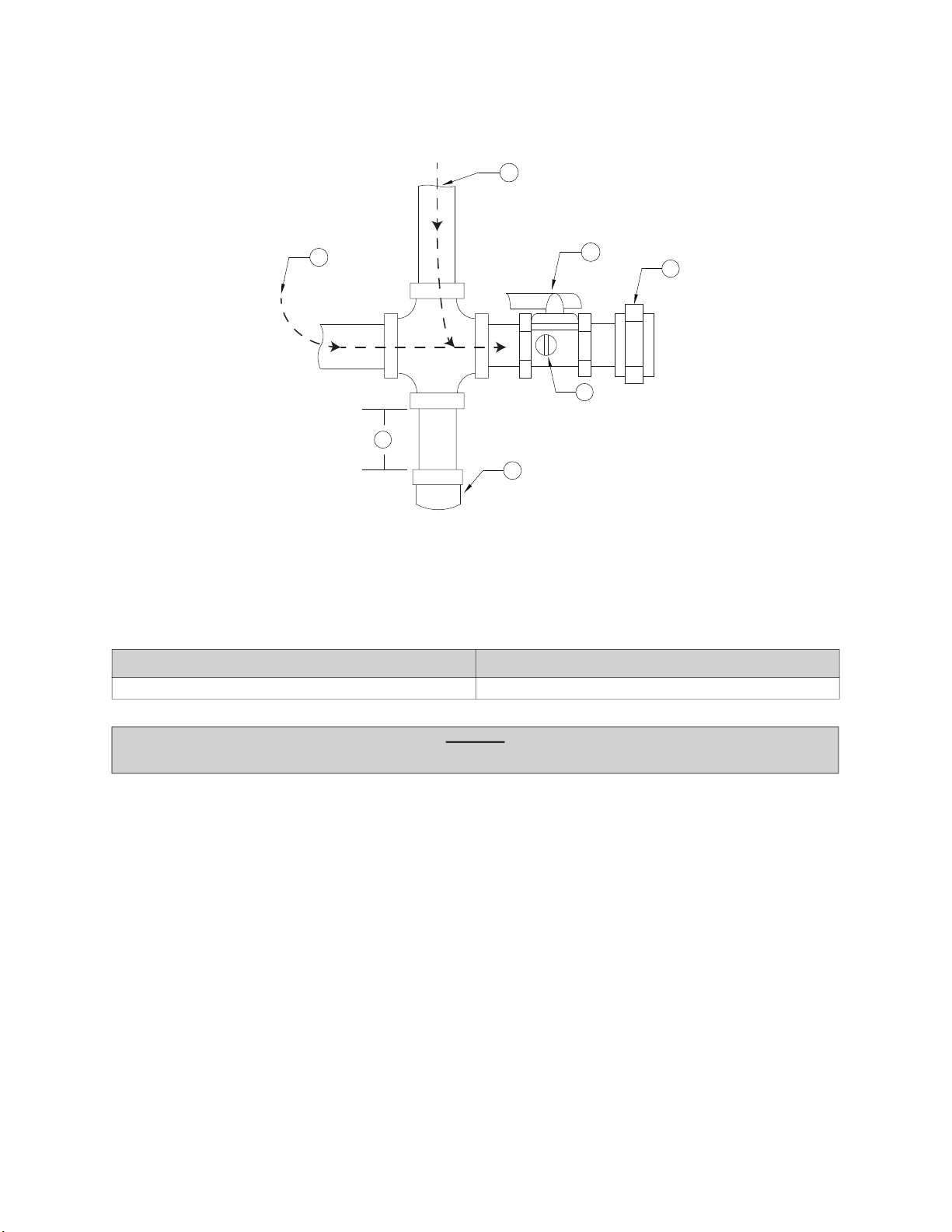

Gas ....................................................................................................................................................................................... 9

ELECTRICAL .......................................................................................................................................................................... 11

Fan to Building Wiring Connection ..................................................................................................................................... 12

Motorized Intake Damper ............................................................................................................................................... 13

Permanent Split Capacitor (PSC) Motor Speed Control .................................................................................................... 13

EVO™/ECM-VCU .......................................................................................................................................................... 13

Electronically Commutated Motor (ECM) Speed Control ................................................................................................... 14

External PWM Signal ..................................................................................................................................................... 14

Unit Mount Controller ......................................................................................................................................................... 14

Motor Speed Controller (MSC) Installation ......................................................................................................................... 15

MSC Controls Overview ..................................................................................................................................................... 16

MSC Menu ..................................................................................................................................................................... 16

Input Threshold .............................................................................................................................................................. 18

MSC Menu Tree ............................................................................................................................................................. 19

Remote Control Panel ........................................................................................................................................................ 20

Motorized Intake Damper ................................................................................................................................................... 20

Electric Cabinet Heater ...................................................................................................................................................... 20

Variable Frequency Drive (VFD) ........................................................................................................................................ 21

Variable Frequency Drive (VFD) Installation .................................................................................................................. 22

Input AC Power .............................................................................................................................................................. 22

VFD Output Power ......................................................................................................................................................... 22

VFD Programming ......................................................................................................................................................... 23

ACTECH SMV VFD ....................................................................................................................................................... 24

OPERATION ........................................................................................................................................................................... 25

Start-up Procedure ............................................................................................................................................................. 25

Pilot Adjustment ................................................................................................................................................................. 26

Main Burner Adjustment ..................................................................................................................................................... 27

Final Start-up Procedure ................................................................................................................................................ 28

Pulley Adjustment ............................................................................................................................................................... 29

Pulley Alignment/Proper Belt Tension ................................................................................................................................ 30

Pulley Combination Chart ................................................................................................................................................... 31

Sequence of Operation ...................................................................................................................................................... 32

Flame Safety Control ..................................................................................................................................................... 32

Modulating Gas System ..................................................................................................................................................... 34

High Temperature Limit ...................................................................................................................................................... 34

Optional Remote Panel Circuit ........................................................................................................................................... 35

Remote Panel Option .................................................................................................................................................... 36

Troubleshooting .................................................................................................................................................................. 37

Burner Troubleshooting ..................................................................................................................................................... 38

Remote Panel Troubleshooting Chart ............................................................................................................................ 39

MSC Troubleshooting .................................................................................................................................................... 40

MAINTENANCE ...................................................................................................................................................................... 41

General Maintenance ......................................................................................................................................................... 41

2 Weeks After Start-up ....................................................................................................................................................... 41

Every 3 Months .................................................................................................................................................................. 41

Yearly ................................................................................................................................................................................. 41

Burner Maintenance ...................................................................................................................................................... 42

Re-Setting of the Unit .................................................................................................................................................... 42

Emergency Shutdown of Unit ........................................................................................................................................ 42

Prolonged Shutdown of the Unit .................................................................................................................................... 42

Start-Up and Maintenance Documentation ........................................................................................................................ 44