4

Carbest 4-Kammer Druckpumpe| Diaphragm Pump | 620560DE

INSTALLATION

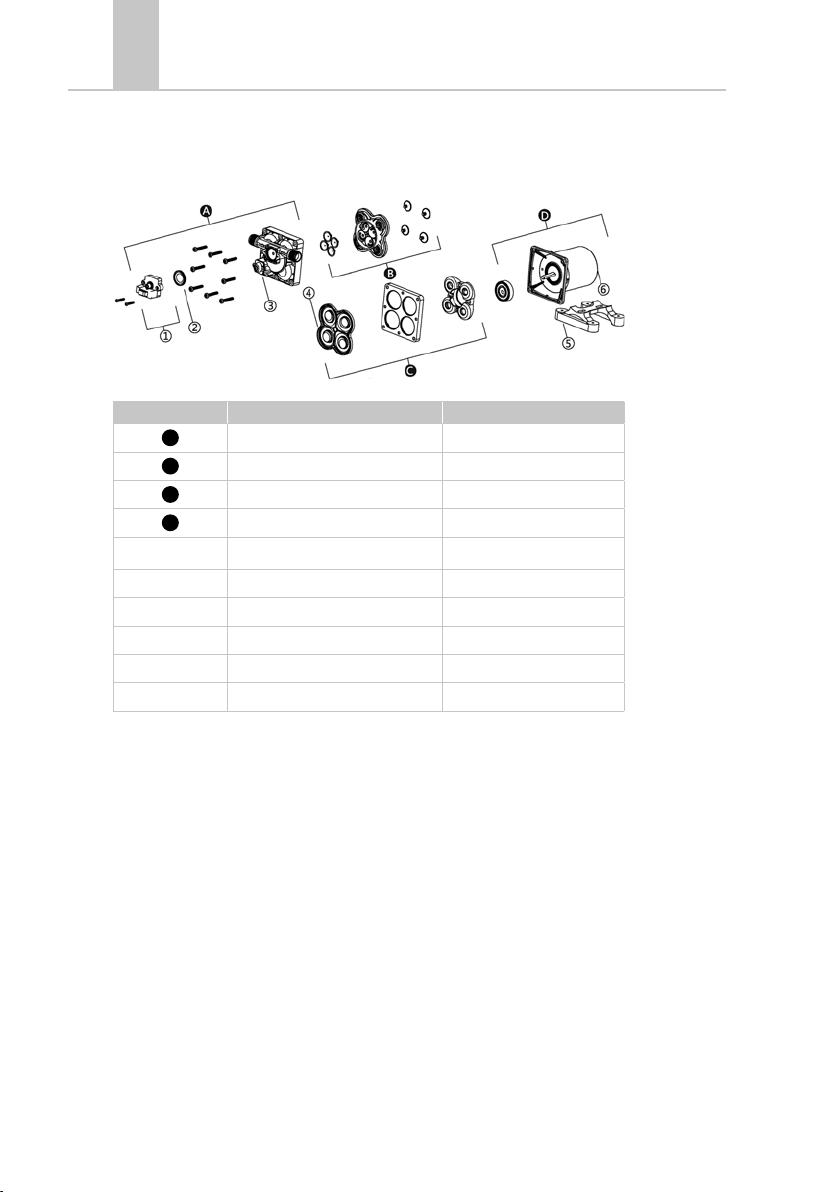

Material

1 Membranpumpe mit Zubehör

2 (mindestens) flexible, verstärkte Schlauchleitungsstücke, mit einer Quetsch-

kraft von zweimal dem kritischen Einlassdruck, Schlauchstärke mindestens

½ Zoll

4 Schlauchklemmen und Schrauben aus Edelstahl

4 Schrauben zur Befestigung der Pumpe an der Montagefläche

1 elektrischer Abschalter

1 Sicherung

1 Schraubendreher

1 starkes Schneidwerkzeug für Schlauchmaterial

(optional) Teflonband oder Dichtmittel

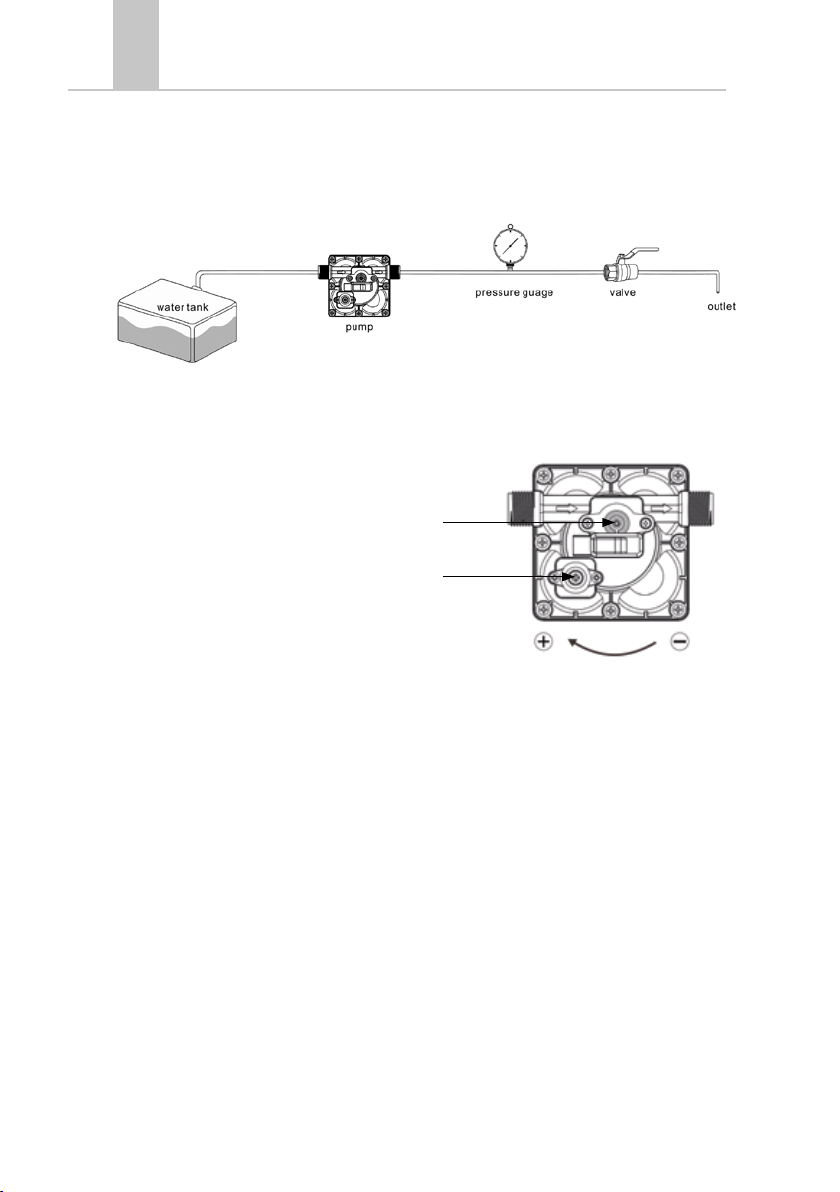

Einrichtung

1. Die Pumpe kann in jeder Position montiert werden. Bei vertikaler Montage

sollte sich der Pumpenkopf in unterer Position befinden, um im Fall einer

Fehlfunktion Auslauf in den Motormantel zu verhindern.

2. Die Füße müssen sicher befestigt werden, dürfen aber nicht zusammen-

gedrückt werden. Durch zu starkes Anziehen der Befestigungsschrauben

kann ihre Fähigkeit zur Ableitung von Geräuschen und Vibrationen reduziert

werden.

3. Der Einlassschlauch muss mindestens ½ Zoll (13 mm) stark und gepanzert

sein. Die Hauptverteilungsleitung vom Pumpenauslass muss ebenfalls ½

Zoll (13 mm) stark sein und die Abzweigungen und einzelnen Zufuhrleitun-

gen zu den Auslässen dürfen nicht kleiner sein als

3

/8Zoll (10 mm).

4. Das System mit umflochtenem Hochdruckschlauch (zweifacher Pumpen-

nennwert) anschließen, um Vibrationen/Geräusche minimal zu halten.

5. Den Einlassdruck unter 30psi halten. Generell sollte Einlassdruck vollständig

vermieden werden.

6. Knicke oder Anschlussstücke vermeiden, die übermäßige Behinderungen

schaffen würden.

7. Der Siebfilter muss an der Einlassseite angebracht werden.

8. Zur Verhinderung von Undichtigkeiten müssen die Anschlussstücke fest

angezogen werden.

9. An beiden Schlauchenden Klemmen anbringen, um Lufteintritt in die Was-

serleitung zu vermeiden.

10. Wenn im Leitungssystem ein Rückschlagventil angebracht wird, muss es

einen Öffnungsdruck von maximal 2 psi haben.

11. Wenn ein Abdichtungs- oder Rohrleitungsband verwendet wird, ist darauf

zu achten, es nicht zu straff festzuziehen, weil es in die Pumpe gesaugt

werden könnte.