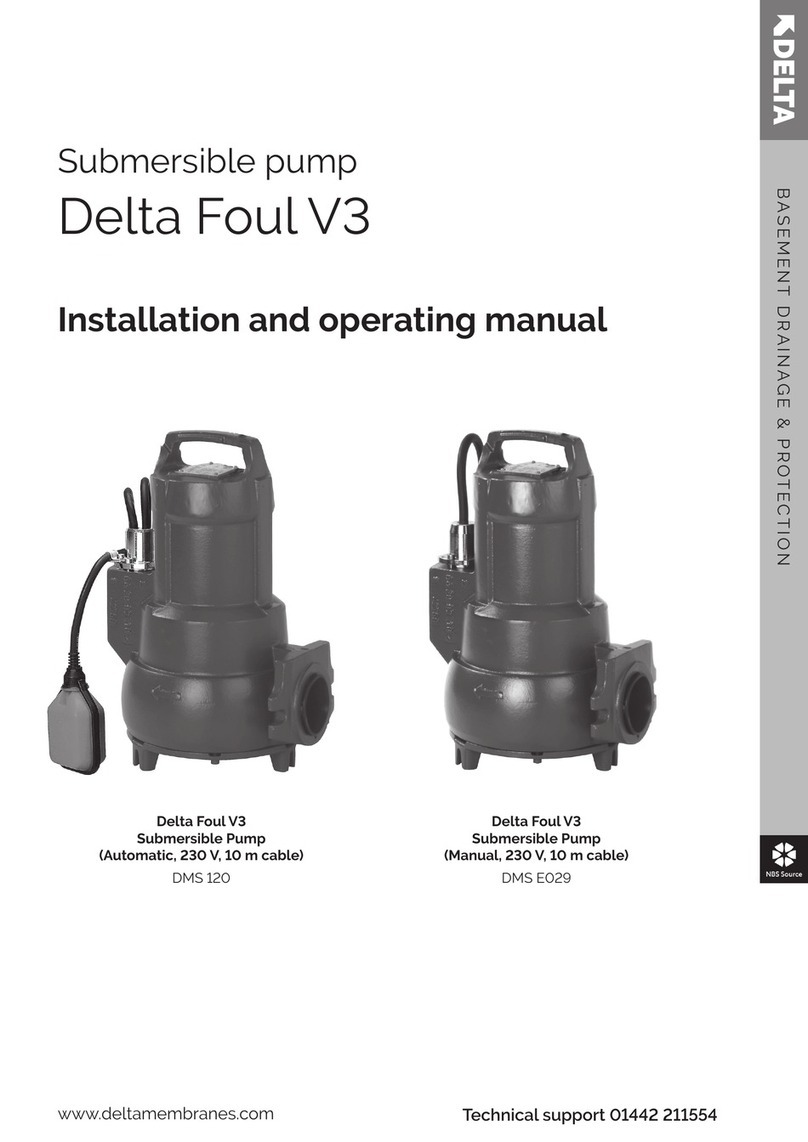

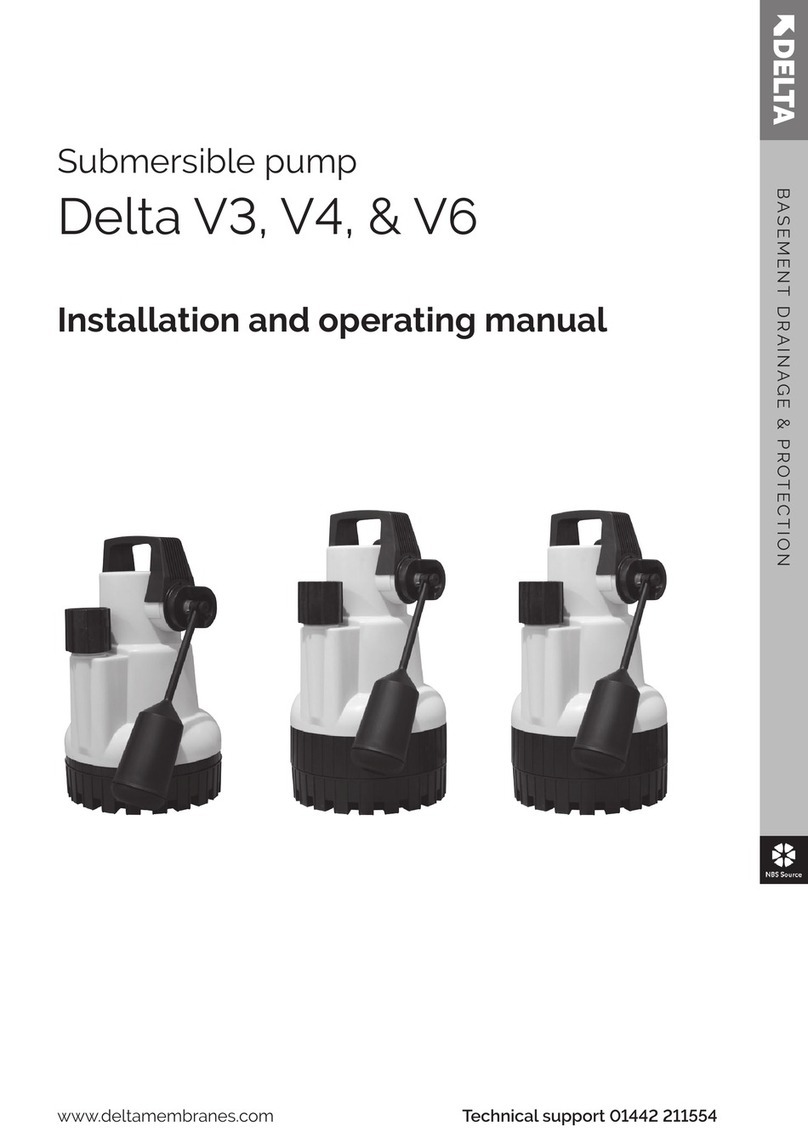

1. Delta Foul V3 Overview

1.0 FOUL V3 OVERVIEW

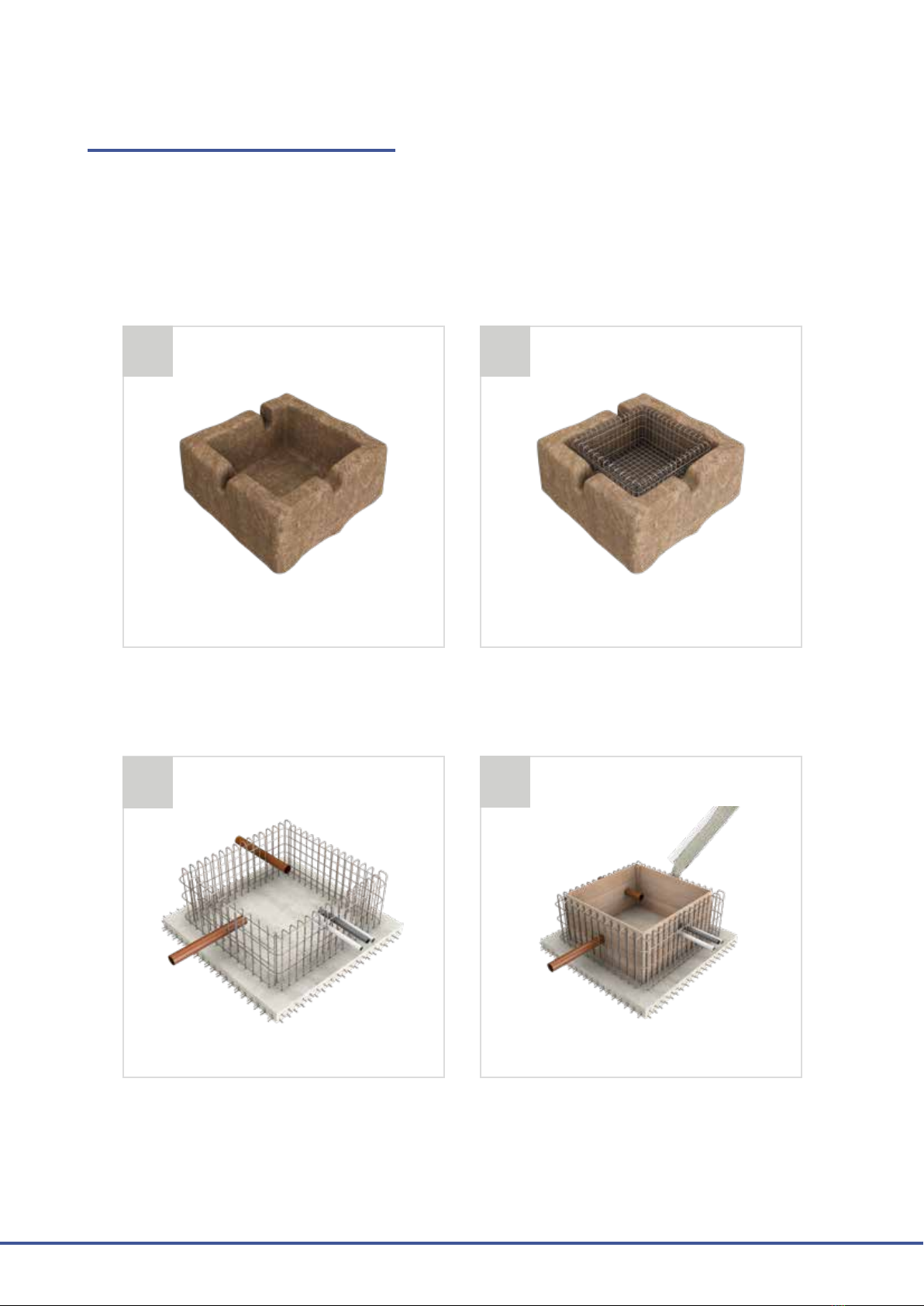

The Delta Foul V3 is a packaged pump station designed to

collect foul water. Typically, the Foul V3 would be used to

bathroom and utility room. This pump station is not designed to

collect groundwaterfrom a cavity membrane system (see Delta

Dual V3 - DMS 164). For kitchen applications we recommend

ground applications. The chamber is manufactured from

HDPE and when installed correctly, it is able to withstand

hydrostatic forces encountered in high water tables.

The pump station is delivered as a complete package

It is designed to be installed by contractors with competent

building, plumbing and electrical skills.

recommended

the water level in the chamber becomes too high. Please see

for the Foul V3 pump station.

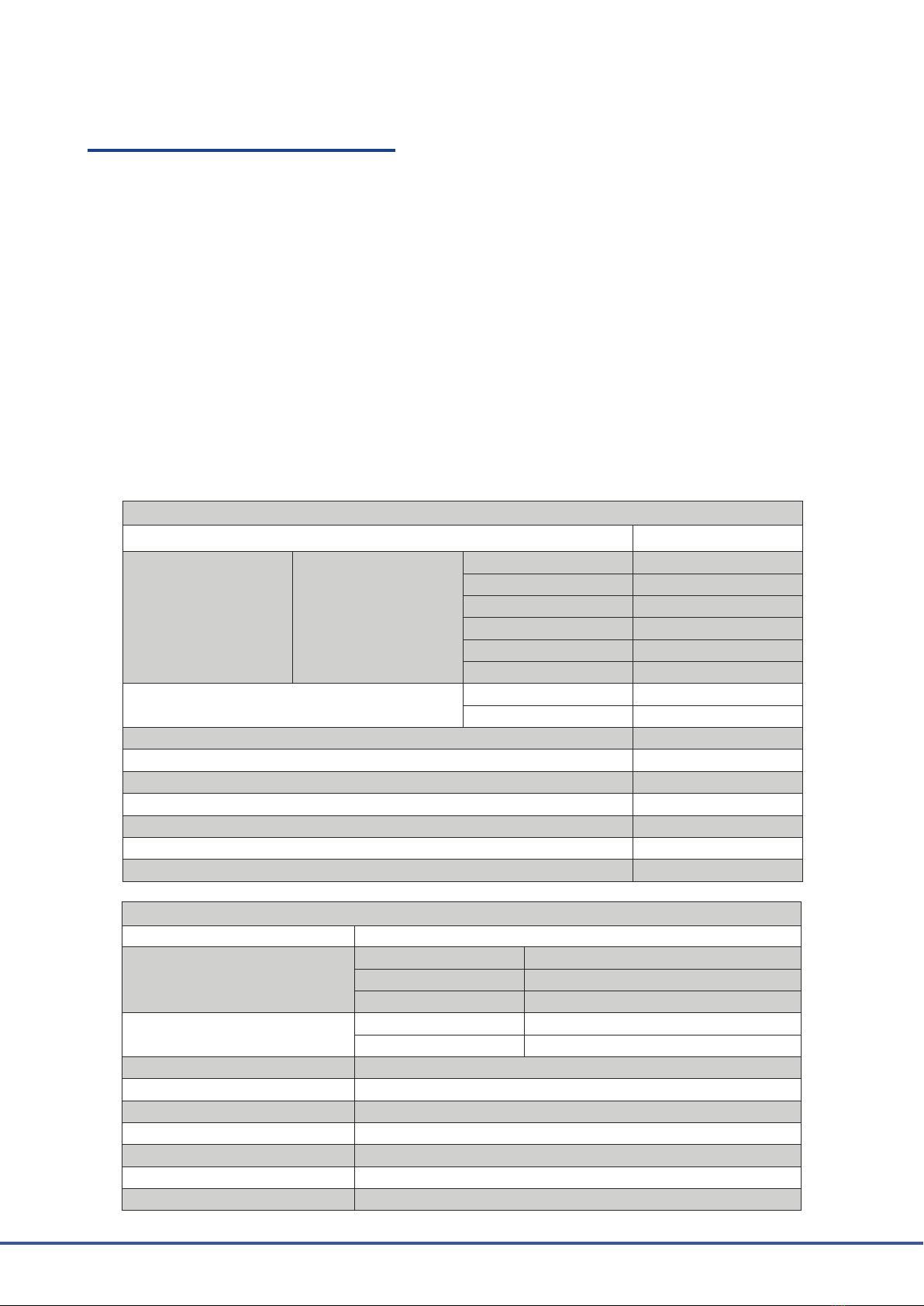

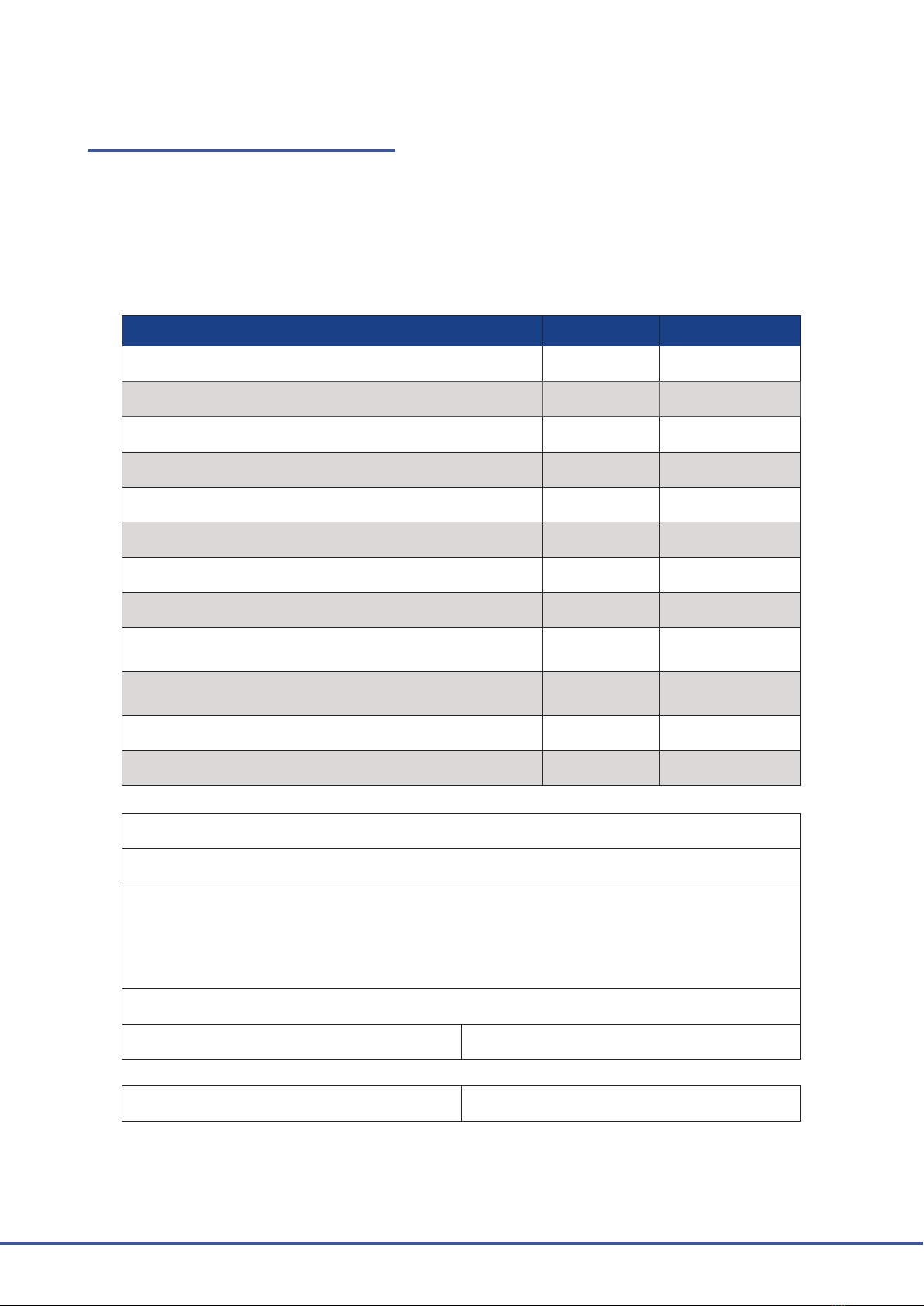

1.1 TECHNICAL INFORMATION

Pump Specication

Pump Type D10SA

Typical Duty (I/S) Head (m)

3 8.30

4 7.50

5 6.30

6 5.00

7 3.70

8 2.30

Power P1(kW) 1.15

P2(kW) 0.75

Current (a) 5.88

Power Phase Single

Non Switched Fuse Spur Rating (a) 13

RCBO Rating (a) 16

Cable Length (m) 10

Max. Temperature (°C) 35

Weight (kg) 13

Chamber Specication

Chamber Material High Density Polyethylene - ICO1314 grade

Size (mm)

Chamber Diameter 660

Overall Diameter 902 (across spigots)

Depth 800

Volume (L)

Below Inlet 137

Total 273

Inspection Cover Not Supplied

Clear opening to chamber (mm) 310 x 310

Fixed Inlets 3 x 110 / 160mm

Cable Duct (mm) 50

Vent (mm) 50

Discharge Connection 2” / 50mm SP Male - External to chamber

Internal Pipework Manifold 2” / 50mm BSP Class E

01992 523 523 | info@deltamembranes.com | www.deltamembranes.com

FOUL V3 INSTALLATION GUIDE

2