REVISED 08/13/2020 TCG-2500-OSP-M © SAM CARBIS SOLUTIONS GROUP, LLC, 2020, WITH ALL RIGHTS RESERVED PAGE 3

1) INTRODUCTION

a) PLEASE READ THIS FIRST PRIOR TO INSTALLATION OR OPERATION

i) On behalf of Sam Carbis Solutions Group LLC., thank you for your purchase of our safety equipment. It is our

pleasure helping you with all your fall protection and product handling needs. We value our customer

relationships and to ensure you get the most out of your equipment, our experienced support team is

available for you to contact throughout your equipment service life. While this manual fully covers our

product, if you should you have any questions or concerns please contact us at 1-800-948-7750 or 1-843-

669-6668 for international customers.

ii) Please carefully read this Installation, Operation, and Maintenance Manual as it is an integral part

of your purchased Carbis equipment. It is the Owner’s responsibility ensuring all personnel who operate

and or maintain the Carbis equipment first receive comprehensive training. It is also the Owner’s

responsibility ensuring appropriately documented maintenance and inspection activities are, including any

abnormal operating condition and its associated root cause evaluation, followed by corrective actions

implemented to eliminate recurrence. Any identified abnormal operating conditions should be cause for

discontinuing use until contacting Sam Carbis Solutions LLC for further assistance.

iii) With aging of equipment and associated service life-limiting variables, such as corrosion, fatigue, wear,

etc., remedy these discrepancies as soon as possible during periodic maintenance to preclude operational

failure.

iv) This manual provides guidance to operating and maintenance personnel in the matter of safe

operation and recommended practices. However, it is not, and cannot be, a substitute for well-trained

personnel. Great reliance must be placed upon the knowledge, background, and experience of the

operating and or maintenance personnel with this manual serving as a guide. Willfully or inadvertently

disregarding the information contained in this equipment manual automatically voids the warranty.

v) This product was inspected prior to shipment and meets Carbis’ Quality Control Standards. It is important

to completely review the information contained in this manual before operating the unit including the

following:

1) Upon delivery, inspect the equipment for shipping damage or any loose or missing hardware. All

factory installed fastening hardware has been tightened prior to shipment. If loosening any fastening

hardware whether factory or field installed, re-tightened accordingly before use.

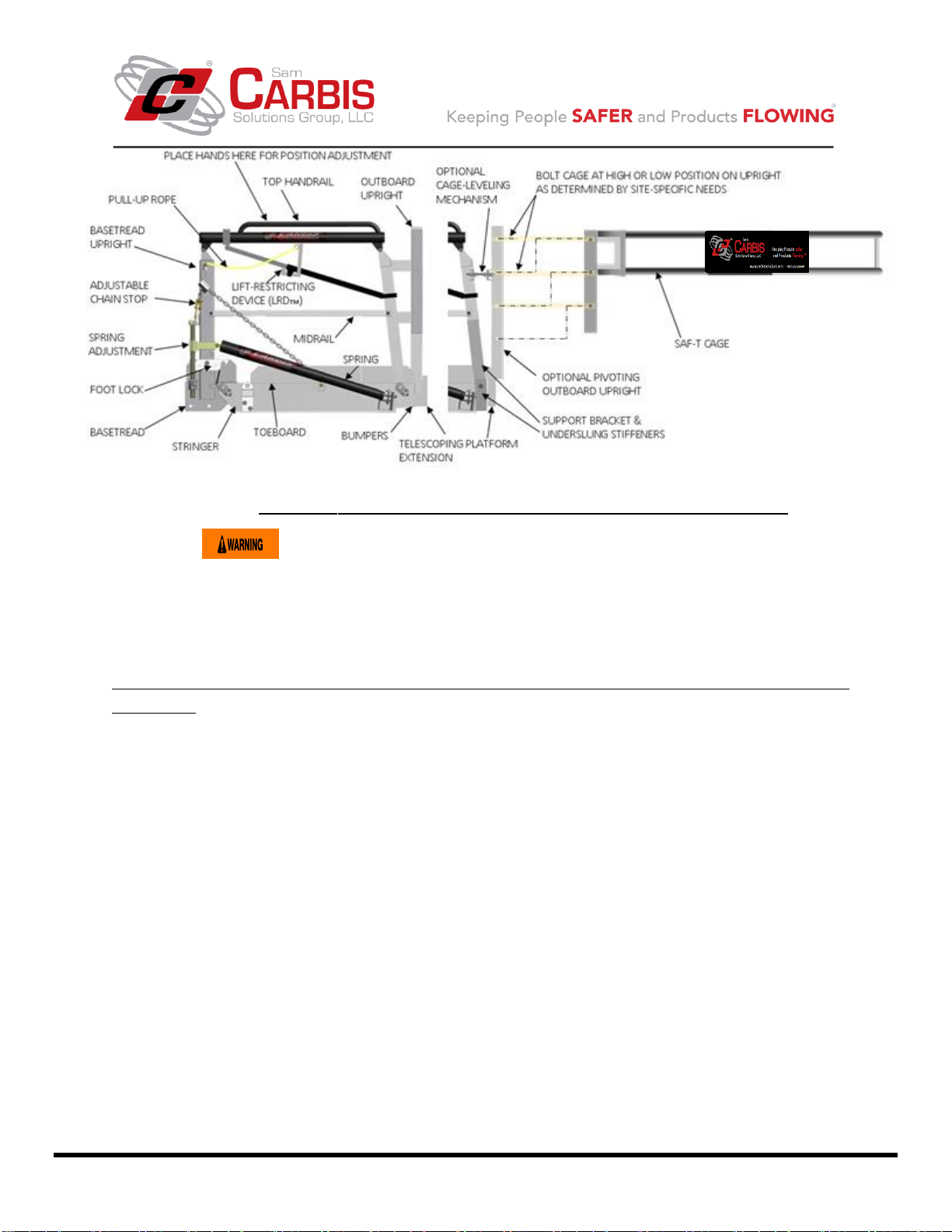

vi) It is imperative operating and maintenance personnel prior to using the equipment become familiar with

the safety information contained in section 3) SAFETY LANGUAGE.

vii) Visually inspect all safety placards, signs, and decals for serviceability, visibility, and legibility. Operating

personnel must be familiar with the contents of such placards, signs, and decals. See Section 3) b) for

SAFETY LABEL DESCRIPTIONS for the description of all safety label and signs that appear on the equipment