2

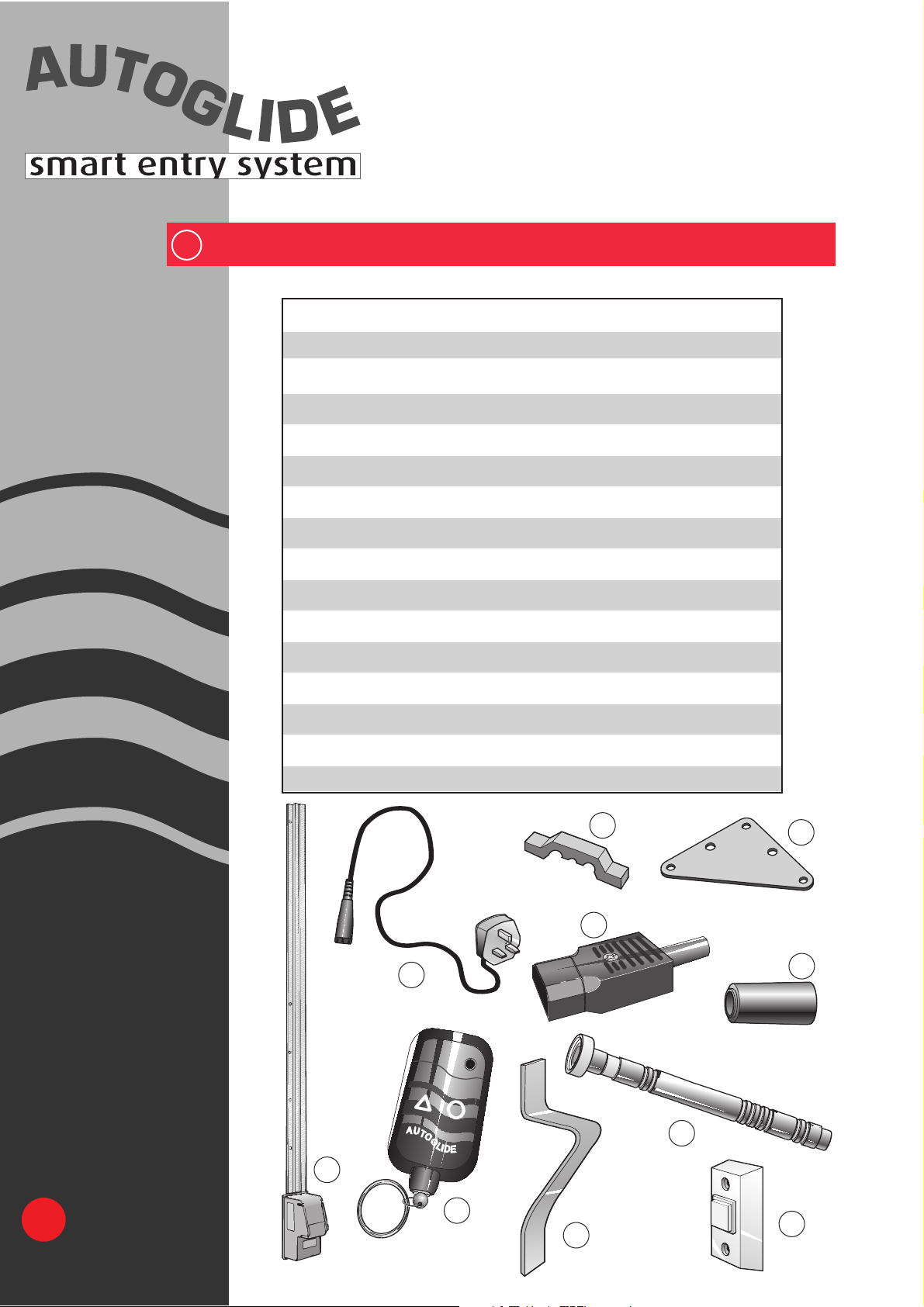

AFit only to Cardale CD 45 and CD PRO garage doors, conversion kits

are required for fitting to other trackless gear systems. (See back page)

BDo not fit Autoglide to any door larger than 8' 0" wide ×7' 0" high

(2438 ×2134mm).

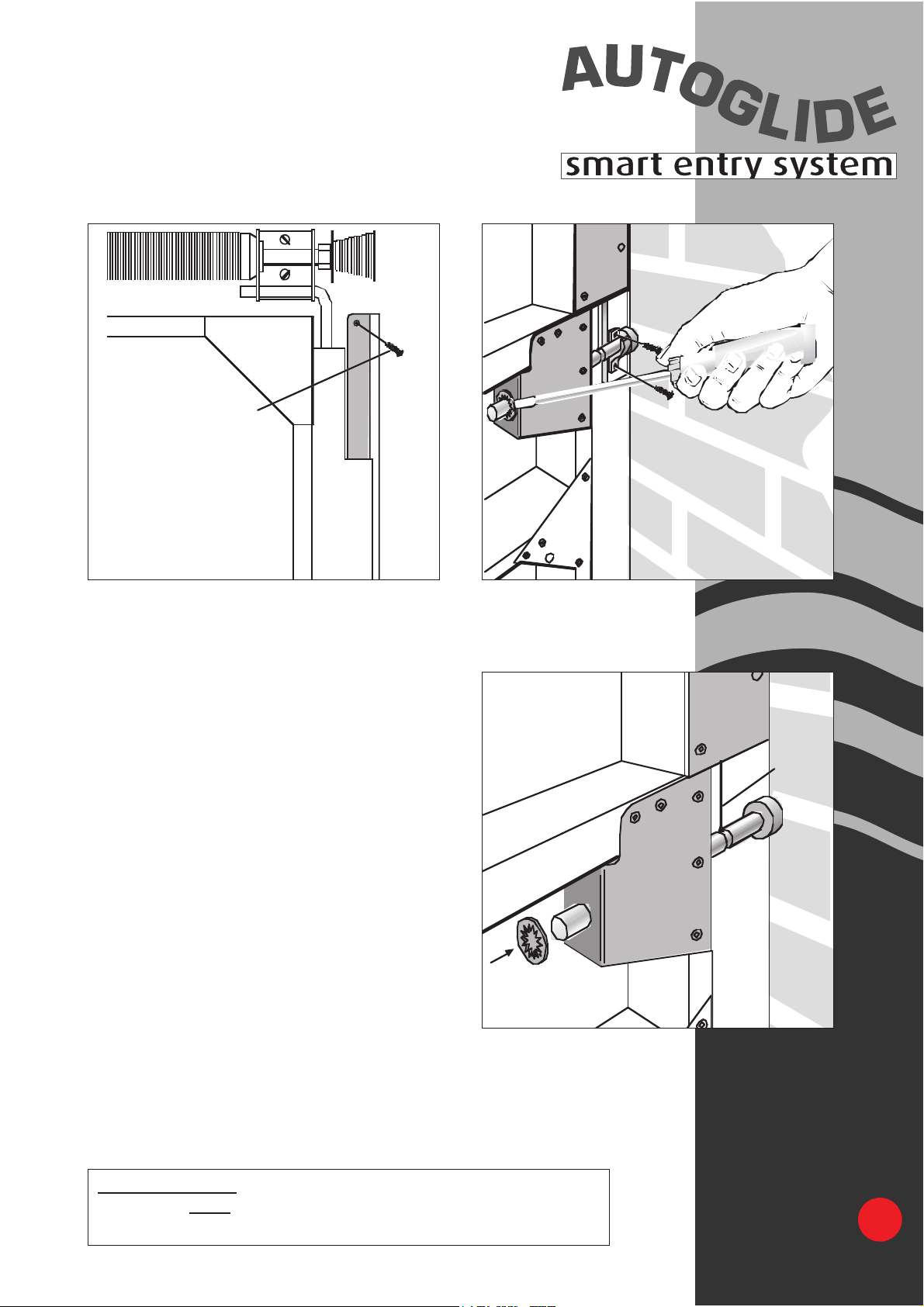

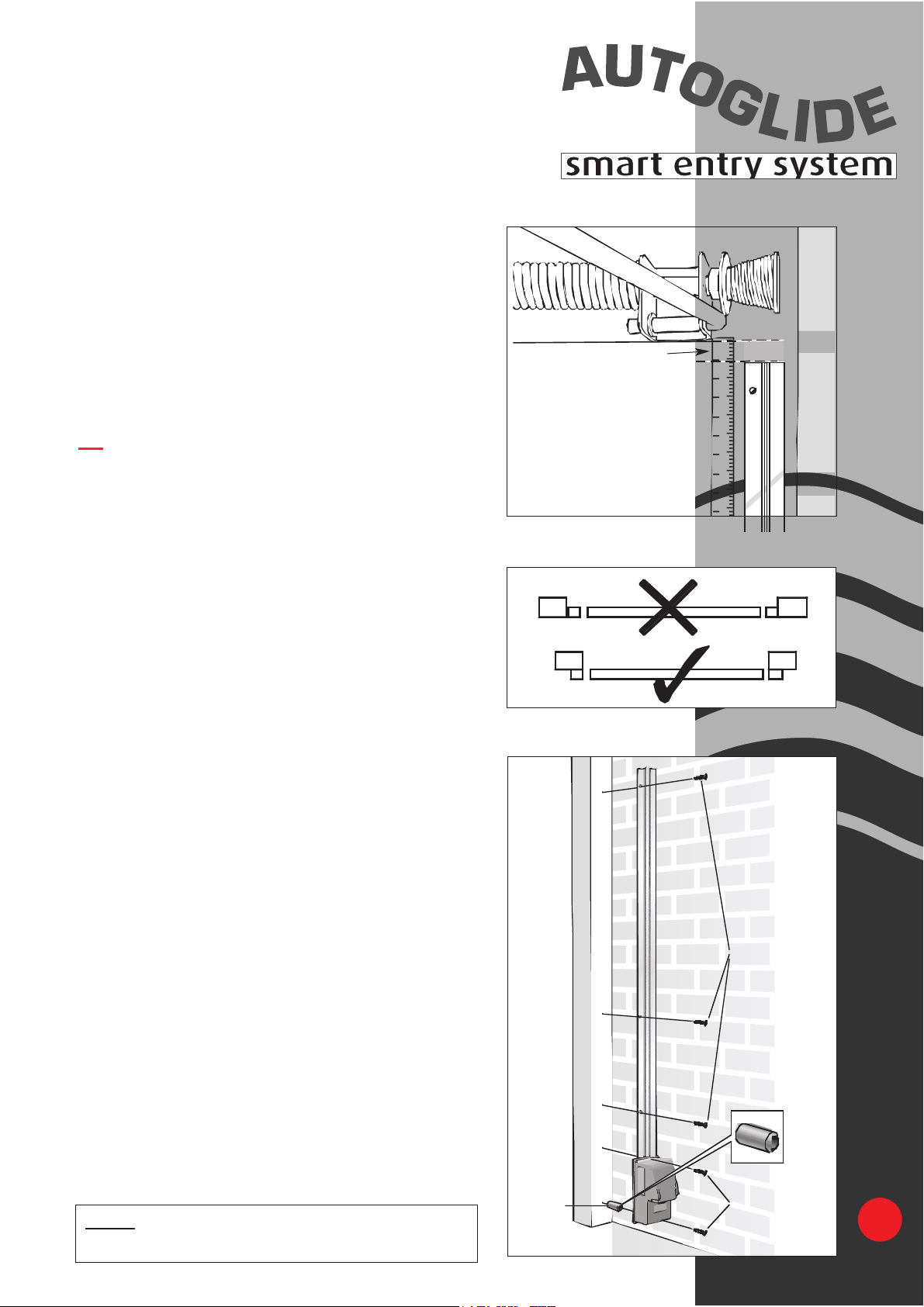

CThe timber “goalpost‘’ frame must be a minimum of 70mm wide at

the right-hand side of the door looking from the inside of the garage and

the frame must be in good condition and securely fixed.

DEnsure the door is correctly tensioned and properly lubricated.

The operator will not function properly if the door is poorly installed in

any way. Also check that lifting cables and gear are in good condition.

EPrior to installing your Autoglide unit ensure all tools, etc are

available inside the garage.

FEnsure that there is a suitably positioned 240v 13A socket outlet

available inside the garage, this must be earthed.

1Pre-installation checks

Installation and wiring must be in compliance with your local building

and electrical codes. Connect the power cord only to properly earthed mains

.

Use a ring main 13 amp 3 pin socket installed by a qualified electrician.

The plug should be fitted with a 5 amp fuse.

THIS APPLIANCE MUST BE EARTHED.

NOTE: For optimum electrical safety this operator should be

connected to a circuit protected by an R.C.D. (max. 30mA trip rating)

If the garage has no service entrance door then an exterior release kit

MUST be fitted. This accessory allows manual operation of the garage

door from outside in case of power failure. (See back page)

Disconnect electric power to the garage door operator before making

repairs or removing covers.

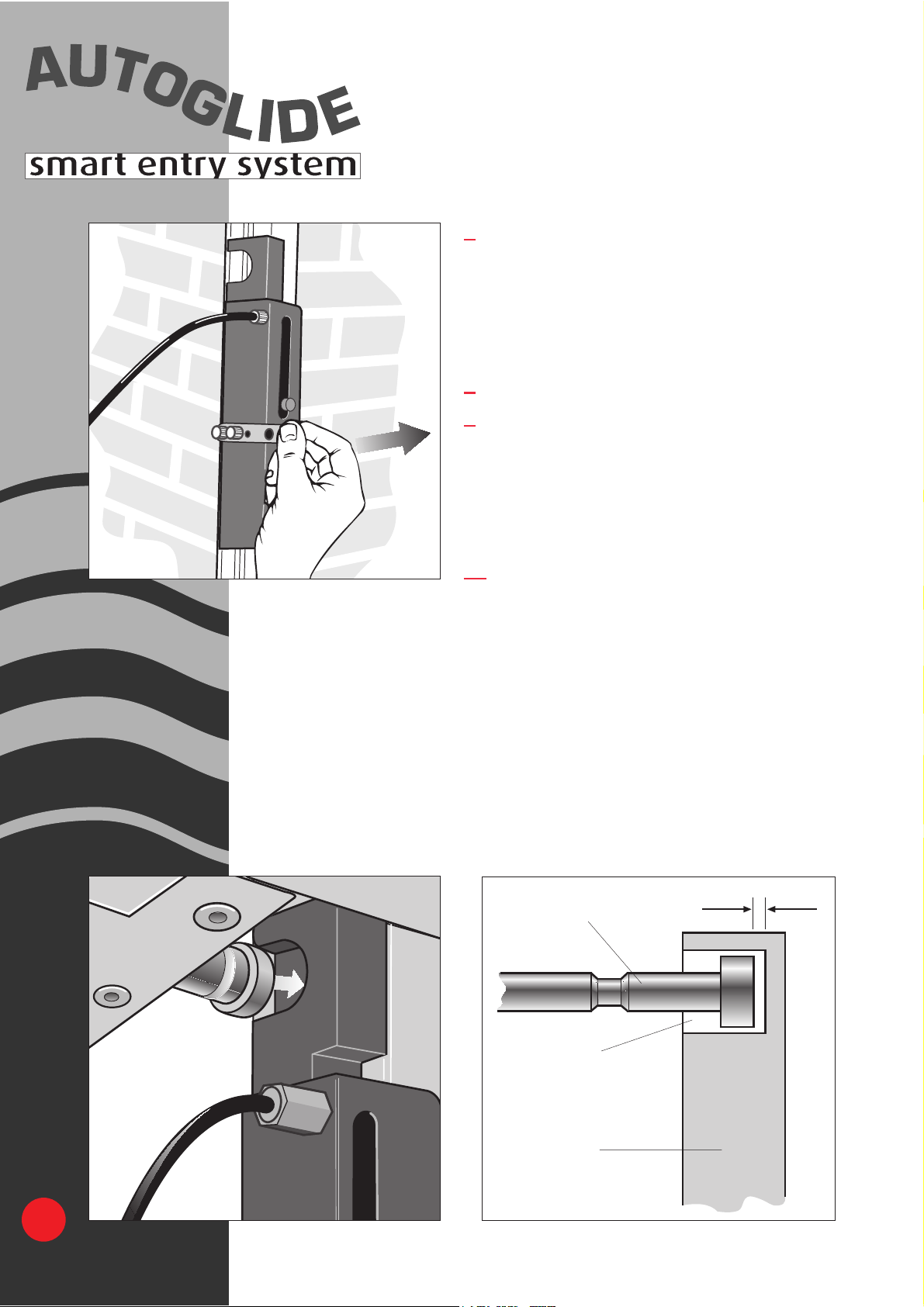

Use the manual release lever to disengage the motor drive ONLY when

the drive is switched OFF and, if possible, when the door is fully closed.

Examine the installation, in particular the cables, spring and

mountings, for signs of wear, damage or imbalance. Do not use if repair

or adjustment is needed since a fault in the installation or an incorrectly

balanced door may cause injury.

IMPORTANT SAFETY NOTE

Only operate the door when the door is in full view, free of obstacles

with no persons (particularly children) near the door. Nobody should

be allowed to enter or leave the garage whilst the door is in motion.