Technical specifications IDO7

The operator is intended to be installed at a height of at least 2.5 m above the floor or other access level.

Dimensions: 340 x 230 x 140 mm (height x width x depth)

Weight: 13.5 kg

Capacity: IDO7; max. door weight 400 kg, IDO7 HD; from 400 kg up to 800 kg, IDO7 2H; max.

door weight 250 kg

Endurance: IDO7: Normally 300000 door cycles depending on door weight and temperature.

IDO7 HD: Normally 100000 door cycles depending on door weight (max 650 kg) and

temperature. For door weights between 650 kg and 800 kg, 50000 door cycles.

Classification: IP65 mech. unit, IP55 control unit (Excluding the CEE-plug which is IP44)

Supply voltage: 230 VAC ± 10%, single phase, 50/60 Hz, 2 A, fuse 10 A

Temperature range: -20°C to +55°C

Normal opening speed down to -8ºC. In the temperature interval between -8ºC to

-20ºC the opening speed is reduced in the first cycle to prolong the operator’s life-

time. Can be equipped with a heater for a working range down to -30°C.

Operating factor: ED = 30 %, S3 10 min, non-continuous operation, equals 30 cycles/hour (ED = 15%

+51° to +55°C)

Atmospheric humidity: 0-80 % relative, no condensation

Installation area: Inside/outside location according to the operator’s specified temp. range

Electrical preparations

The manually operated door needs no electrical supply.

For an electrically operated door, the following environment criteria and electrical supplies are required for the

operator to function properly:

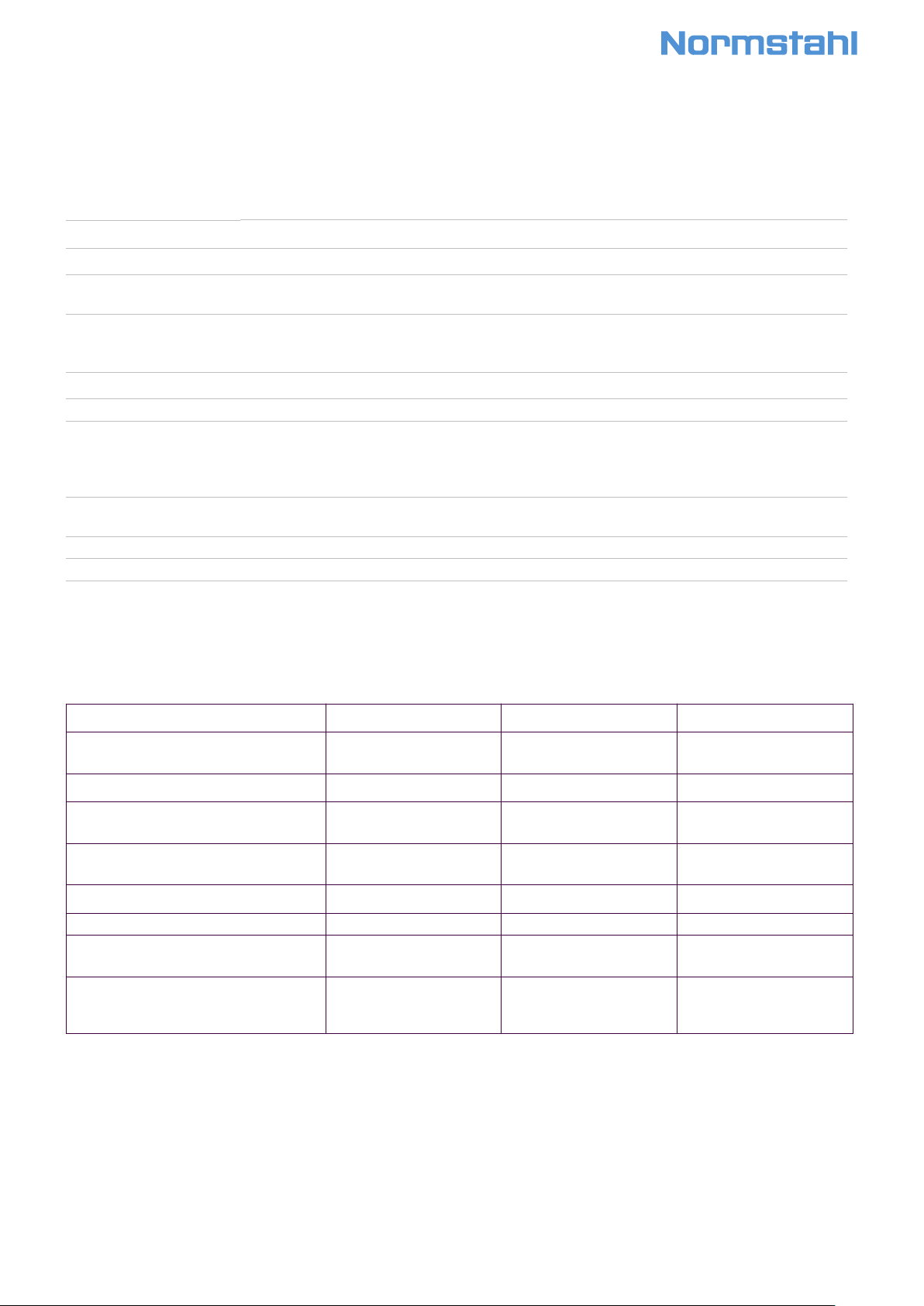

IDO7 IDO7 HD IDO7 2H

Voltage supply: +/- 10% 230 VAC

1-phase 50/60Hz

230 VAC

1-phase 50/60Hz

230 VAC

1-phase 50/60 Hz

Power: 0.37 kW 0.6 kW 0.37 kW

Degree of protection: IP65 / IP55,

excl. connector IP 44

IP65 / IP55,

excl. connector IP 44

IP65 / IP55,

excl. connector IP 44

Opening/Closing speed: 0,25 m/s 0,18 m/s 0,5 m/s opening

0,25 m/s closing

Allowed door weight, max.: 400 kg 800 kg 250 kg

Temperature working range: -20 °C to +55 °C -20 °C to +55 °C -20 °C to +55 °C

Operating factor: ED = 30%

S3 10 min. intermittent

ED = 30%

S3 10 min. intermittent

ED = 30%

S3 10 min. intermittent

Mounting preparations: When installing on the

wall, an extra attach-

ment angle is required

Installation Manual

IDO7/C700

IDO7 operator 6

1.3

1.4