!IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLATION

WARNING – INCORRECT INSTALLATION CAN LEAD TO SEVERE INJURY

FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY

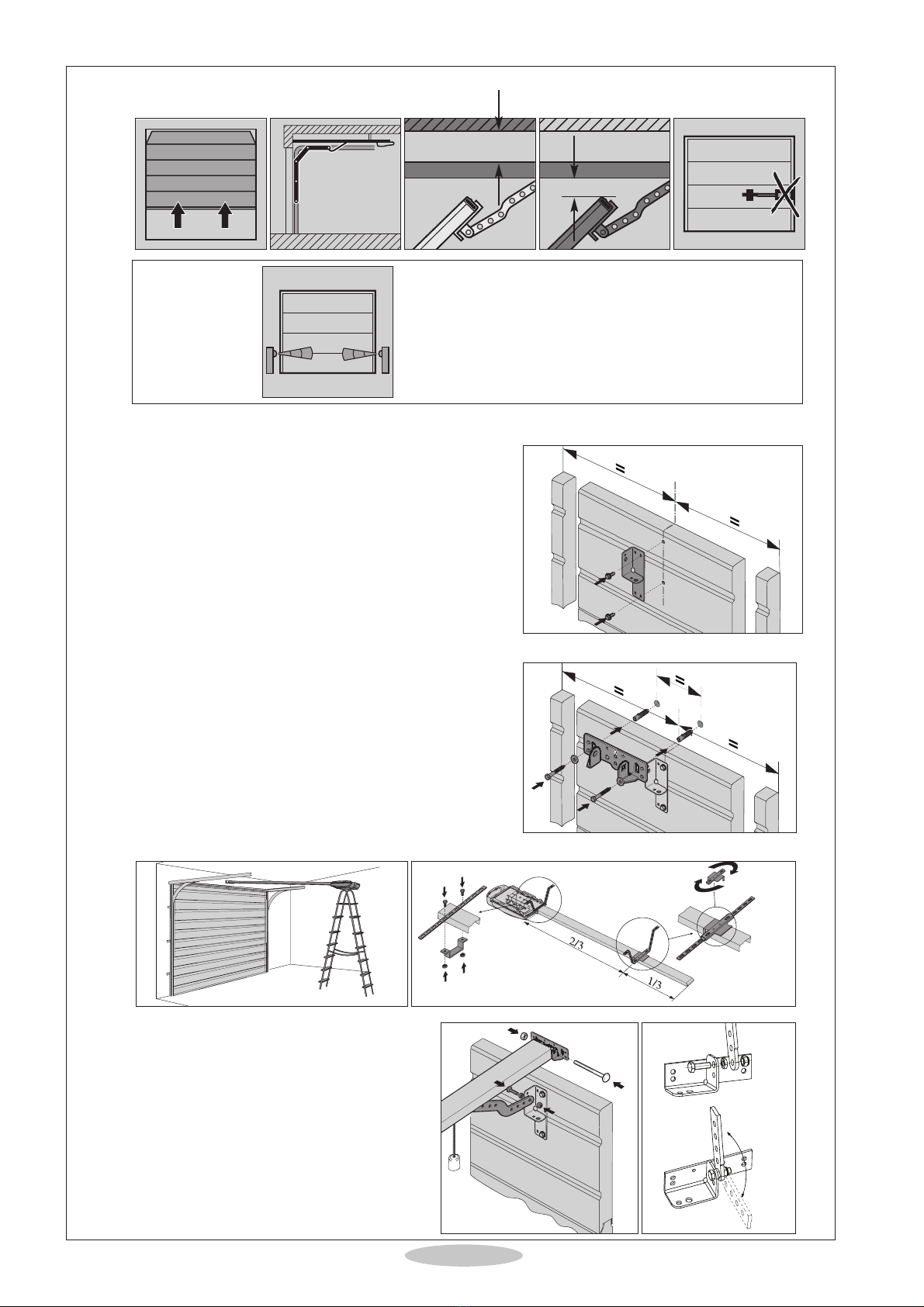

Before installing the operator check that the door is in good mechanical condition,

and correctly balanced, and that it opens and closes properly.

•Do not use the force adjustments to compensate for a binding or sticking garage door.

Excessive force will interfere with the proper operation of the Safety Reverse System

or damage the garage door.

•

Do not wear rings, watches or loose clothing while installing or servicing a garage

door operator.

•To avoid serious personal injury from entanglement, remove any ropes connected to

the garage door before installing the door operator.

•Install the remote mounted bell push button within sight of the door but away from

any moving parts and at a height of at least 1.5 metres.

•The safety reverse system test is very important. The garage door must reverse when

obstructed on closing. Failure to properly adjust the operator may result in serious

personal injury from a closing garage door. Repeat the test once a month and make

any needed adjustments (see Menudand Menu5on page 10 of this manual).

Installation and wiring must be in compliance with your local building

and electrical codes.

The plug on cord is fitted with a 3 amp fuse.

NOTE: For optimum electrical safety this operator should be connected to a circuit

protected by an R.C.D.

•If the garage has no service entrance door then an exterior release kit MUST be fitted.

This accessory allows manual operation of the garage door from outside in case of

power failure. (See back page)

•Disconnect electric power to the garage door operator before making repairs or

removing covers.

•Use the manual release lever to disengage the motor drive ONLY when the drive is

switched OFF and, if possible, when the door is fully closed.

•Examine the installation, in particular the cables, spring and mountings, for signs of

wear, damage or imbalance. Do not use if repair or adjustment is needed since a fault

in the installation or an incorrectly balanced door may cause injury.

IMPORTANT SAFETY NOTE

Only operate the door when the door is in full view, free of obstacles with no persons

(particularly children) near the door. Nobody should be allowed to enter or leave the

garage whilst the door is in motion.

Page 2