Page 4

3. General safety advice

Beside the advice in these instructions, please observe the general precaution and safety regulations!

Our sales and supply terms and conditions are effective.

Advice for installation of the operator

• Make sure that the door is in good mechanical condition.

• Make sure, that the door is balanced.

• Make sure that the door opens and closes correctly.

• Remove all components that are not required (e.g. cords, chains, angles etc.).

• Switch off all devices which will not be needed after the operator is installed.

• Before laying cables, the operator must be disconnected from the power supply.

Wait 10 seconds to be sure that the operator is without power.

• Observe the local safety regulations.

• Always lay mains and control cables separately. The control voltage is 24 V DC.

• Only mount the operator when the door is closed.

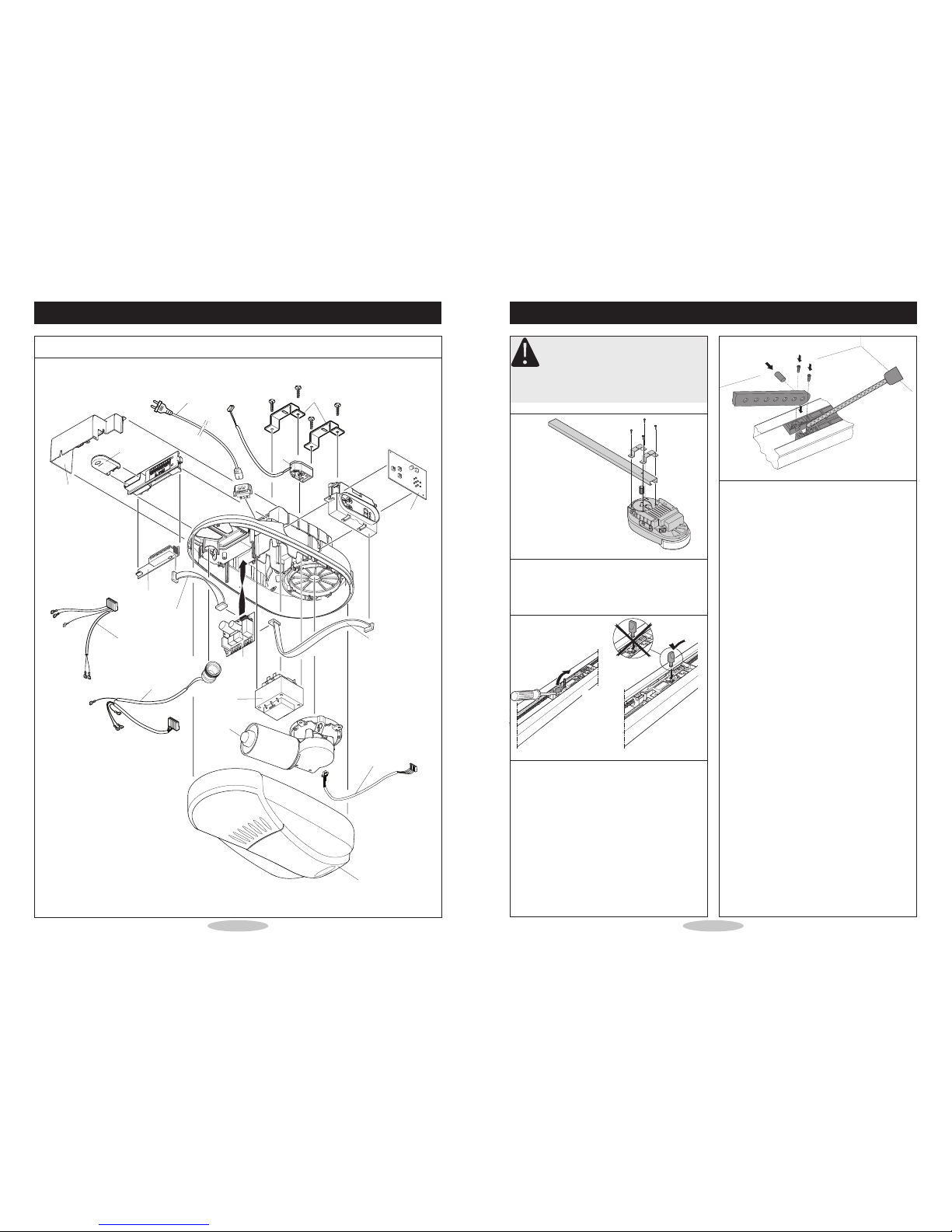

• Install all impulse and control devices (e.g. RC code keypad) within sight to the door and at a safe distance from

movable parts of the door. A minimum mounting height of 1.5 m must be maintained.

• Permanently attach the warning decals against jamming in a clearly visible place.

• Following installation, ensure that door parts do not protrude onto public footpaths or streets.

Advice for initial operation of the operator

After initial operation, the door system operating personnel or their proxies must be familiarised with the use of the

system.

• Make sure that children cannot access the door control unit.

• Before moving the door, make sure that there are neither persons nor objects in the operating range of the door.

• Test all existing emergency command devices.

• Never insert your hands into a running door or moving parts.

Advice for maintenance of the operator

To guarantee problem-free operation, regularly check and, if necessary, repair the following aspects. Always disconnect

the operator from the power supply before carrying out any work on the door system.

• Check monthly whether the operator reverses when the door encounters an obstacle. Depending on the door’s

operational direction, place a 50 mm high/wide obstacle in the door travel path.

• Check the settings of the "OPEN" and "CLOSE" automatic cut-out function.

• Check all movable parts of the door and operator system.

• Check the door system for signs of wear or damages.

• Check whether the door can be easily moved by hand.

Advice for cleaning the operator

For cleaning never use: water jets, high pressure cleaners, acids or bases.

• Clean the operator with a dry cloth if necessary.