cod. +050000157 - rel. 1.0 - 08.09.2004

HYVC000R0*

Scheda per controllo elettronico fan coil /

Board for fan coil electronic controller

Vi ringraziamo per la scelta fatta, sicuri che sarete

soddisfatti del vostro acquisto.

Introduzione

Questo dispositivo permette al controllo elettronico fan coil

(Cod. HYF*******) di gestire i carichi aggiuntivi al ventilatore;

come valvole di spillamento dagli anelli di acqua calda e fredda,

pompa di circolazione, alimentazione del relè esterno per la

resistenza di riscaldamento e le richieste di acqua calda e fredda

al chiller/pompa di calore e caldaia.

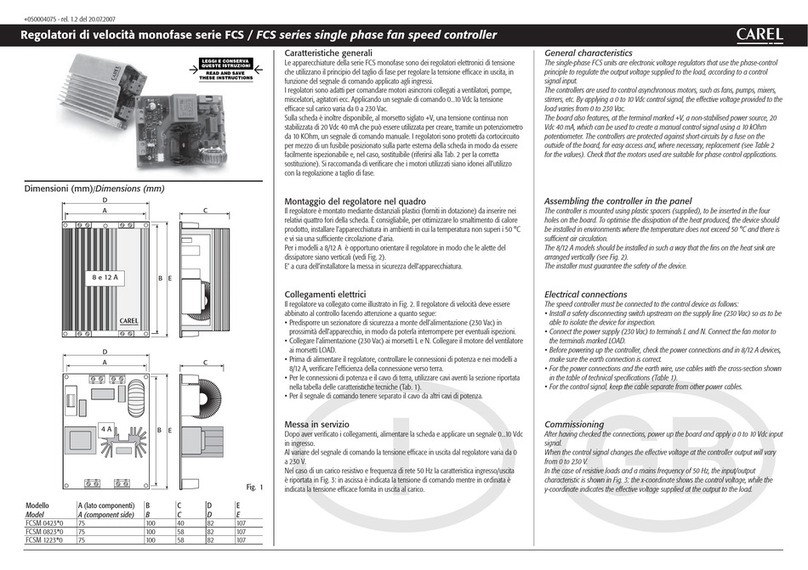

Significato dei morsetti

Morsetto Significato

SUPPLY EXP Connettore per l’alimentazione dell’espansione

fan coil (tramite cavo a 2 vie)

EXP Connettore per collegamento dell’espansione

fan coil (tramite cavo a 5 vie)

N Neutro

NO4 Alimentazione elettrovalvola acqua fredda.

Uscita in tensione (L).

NO5 Alimentazione elettrovalvola acqua calda.

Uscita in tensione (L).

NO6 Contatto pulito acqua calda

NO7 Contatto pultio acqua fredda

Nota: per i relè NO 4, 5, 6 e 7 controllare le impostazioni sul

manuale d’uso fan coil.

Lunghezza max. cavi:

uscite in tensione N°4 e N°5: 5 m

uscite digitali NO6 e NO7: 30 m (come contatto pulito),

5 m (come consenso

alimentazione eventuale carico).

Avvertenze d’installazione

• Effettuare tutte le operazioni di installazione e manutenzione a

macchina non alimentata.

• Adottare precauzioni contro le scariche elettrostatiche nel

maneggiare la scheda (ES braccialetto antistatico).

• In caso di utilizzo di schede di comunicazione seriale l’impiego

dell’uscita N°7 potrebbe essere limitata alla sola bassissima

tensione. Consultare manuale d’uso.

Protezione contro le scosse elettriche

Il sistema composto dalla scheda controllo (HYFC******) e dalle

altre schede opzionali (HYVC000R0*, HYPA******, HYIR******,

HYSC00F0C*, schede seriali pCO, ecc.) costituisce un

dispositivo di comando da incorporare in apparecchiature di tipo

classe I o II. La classe relativa alla protezione contro le scosse

elettriche dipende dalla modalità con cui viene eseguita

l'integrazione del dispositivo di comando nella macchina

realizzata dal costruttore.

La protezione contro i cortocircuiti deve essere garantita dal

costruttore dell'apparecchiatura in cui il dispositivo di comando

viene integrato o dall’installatore finale.

Interfaccia utente e modifica parametri

Per l’impostazione dei parametri è richiesto l’utilizzo della scheda

fan coil e di uno dei seguenti dispositivi: telecomando, pannello

LCD o scheda seriale.

Thank you for having chosen this product. We trust

you will be satisfied with your purchase.

Introduction

This device allows the fan coil electronic controller

(Code HYF*******) to control the other loads in addition to the

fan; as bleed valves in the hot and cold water loops, pumps,

power supply to the external relays for the heaters and the hot

and cold water requests to the chiller/heat pump and boiler.

Terminal meaning

Terminal Meaning

SUPPLY EXP Fan coil expansion power supply connector

(2-wire cable)

EXP Connector for the fan coil expansion

(5-wire cable)

N Neutral

NO4 Cold water solenoid valve power supply.

Voltage output (L).

NO5 Hot water solenoid valve power supply.

Voltage output (L).

NO6 Hot water voltage-free contact

NO7 Cold water voltage-free contact

Note: check the setting of the NO relays 4, 5, 6 and 7 in the fan

coil user manual.

Max cable length:

voltage outputs NO4 and NO5: 5 m

digital outputs NO6 and NO7: 30 m (voltage-free contact),

5 m (to enable power supply to

any loads).

Installation guidelines

• All installation and maintenance operations must be carried out

with the unit off.

• Adopt precautions against electrostatic discharges when

handling the board (e.g. antistatic bracelet).

• If using serial communication cards, output No7 may be limited

to very low voltage uses only. Consult the user manual.

Protection against electric shock

The system made up of the control board (HYFC*****) and the

other optional cards (HYVC000R0*, HYPA******, HYIR******,

HYSC00F0C*, pCO serial cards etc..) constitutes a control

device to be incorporated into class I or II units. The class of

protection against electric shock depends on how the control

device is integrated into the unit built by the manufacturer.

Protection against short-circuits must be guaranteed by the

manufacturer of the unit that the control device is integrated into

or by the installer.

User interface and parameter settings

To set the parameters, the fan coil board and one of the following

devices are required: remote control, LCD panel or serial card.