CONTENT

1APPLICATIONS AND FUNCTIONS PERFORMED BY THE SOFTWARE........................................................................................3

2THE USER TERMINAL............................................................................................................................................................................... 4

3PLAN MANAGEMENT AMONG CARDS.................................................................................................................................................6

3.1 HOW TO ASSIGN THE PLAN ADDRESSES....................................................................................................................................... 6

4INSTALLING DEFAULT VALUES............................................................................................................................................................7

5SELECTING THE LANGUAGE ................................................................................................................................................................. 7

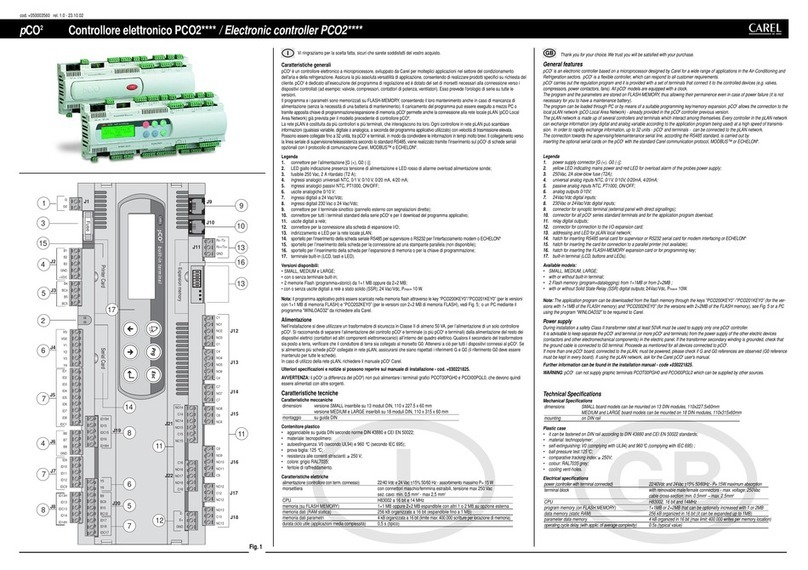

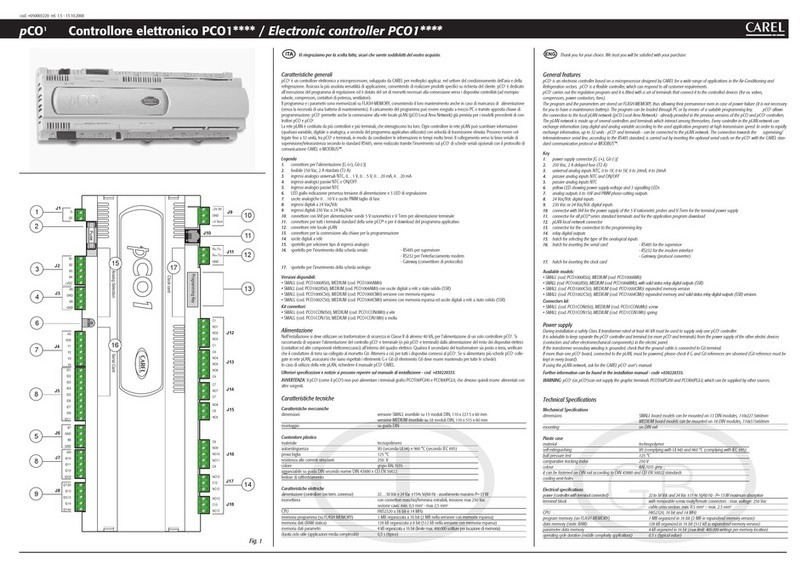

6LIST OF INPUTS/OUTPUTS.......................................................................................................................................................................8

6.1 CHILLER-ONLY UNIT - MACHINE TYPE “0”................................................................................................................................... 8

6.2 CHILLER UNIT + HEAT PUMP – MACHINE TYPE “1”..................................................................................................................... 9

6.3 CHILLER UNIT WITH FREECOOLING – MACHINE TYPE “2”..................................................................................................... 10

6.4 CHILLER-ONLY UNIT – MACHINE TYPE “3”................................................................................................................................. 11

6.5 CHILLER UNIT + HEAT PUMP WITH GAS REVERSING – MACHINE TYPE “4”....................................................................... 12

6.6 CHILLER UNIT + HEAT PUMP WITH WATER REVERSING – MACHINE TYPE “5”................................................................. 13

7LIST OF PARAMETERS ........................................................................................................................................................................... 14

8SCREENS..................................................................................................................................................................................................... 19

8.1 LIST OF SCREENS............................................................................................................................................................................... 19

9ELECTRONIC EXPANSION VALVE...................................................................................................................................................... 20

9.1 DRIVER PARAMETERS...................................................................................................................................................................... 20

9.2 SPECIAL FUNCTION "IGNORE"........................................................................................................................................................ 21

10 CONTROL................................................................................................................................................................................................ 22

10.1 INLET TEMPERATURE CONTROL ............................................................................................................................................................ 22

10.2 OUTLET TEMPERATURE CONTROL......................................................................................................................................................... 23

10.3 CONTROL OF WATER /WATER CHILLER ONLY UNITS.............................................................................................................................. 23

10.4 CONTROL OF WATER/WATER CHILLER UNIT WITH GAS REVERSING HEAT PUMP....................................................................................... 24

10.5 CONTROL OF WATER/WATER CHILLER UNIT WITH WATER REVERSING HEAT PUMP.................................................................................. 24

11 TYPES OF CONTROLLED COMPRESSORS .................................................................................................................................... 25

11.1 STEPPED CAPACITY CONTROL............................................................................................................................................................... 25

11.2 STEPPED CAPACITY CONTROL WITH CONTROL AT INLET ........................................................................................................................ 26

11.3 STEPPED CAPACITY CONTROL WITH CONTROL AT OUTLET ..................................................................................................................... 26

11.4 CONTINUOUS CAPACITY CONTROL........................................................................................................................................................ 27

11.5 CONTINUOUS CAPACITY CONTROL WITH CONTROL AT OUTLET .............................................................................................................. 28

12 COMPRESSOR ROTATION................................................................................................................................................................. 29

13 STARTING A SINGLE COMPRESSOR.............................................................................................................................................. 30

13.2 STARTING THE COMPRESSOR MOTOR .................................................................................................................................................... 30

13.3 COMPRESSOR START RESTRICTIONS...................................................................................................................................................... 30

14 FORCED CAPACITY CONTROL........................................................................................................................................................ 31

15 SOLENOID-VALVE MANAGEMENT................................................................................................................................................. 32

16 PUMP-DOWN.......................................................................................................................................................................................... 32

17 CONDENSATION CONTROL .............................................................................................................................................................. 33

17.1 ON/OFF CONDENSATION LINKED TO OPERATION OF COMPRESSOR:...................................................................................................... 33

17.2 ON/OFF CONDENSATION LINKED TO PRESSURE OR TEMPERATURE SENSOR :........................................................................................ 33

17.3 MODULATING CONDENSATION LINKED TO PRESSURE OR TEMPERATURE SENSOR :.................................................................................. 33

17.4 PREVENT FUNCTION:............................................................................................................................................................................ 33

18 DEFROSTING CONTROL FOR WATER/AIR MACHINES............................................................................................................ 34

18.1 TYPES OF DEFROSTING ......................................................................................................................................................................... 34

18.2 TYPE OF DEFROSTING START/END......................................................................................................................................................... 34

18.3 DEFROSTING A CIRCUIT WITH TIME/TEMPERATURE CONTROL ................................................................................................................ 34

18.4 DEFROSTING A CIRCUIT WITH TIME/PRESSURE SWITCHES CONTROL ....................................................................................................... 34

18.5 OPERATION OF FANS DURING THE DEFROSTING STAGE .......................................................................................................................... 34