Deif CGC 400 Product guide

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive · Tel.: +45 9614 9614 · Fax: +45 9614 9615 · info@deif.com · www.deif.com

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive · Tel.: +45 9614 9614 · Fax: +45 9614 9615 · info@deif.com · www.deif.com

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive · Tel.: +45 9614 9614 · Fax: +45 9614 9615 · info@deif.com · www.deif.com

DESIGNER'S REFERENCE HANDBOOK

Compact Genset Controller, CGC 400

● General product information

● Functional description

● Additional functions

● Protections

Document no.: 4189340786B

SW version: 1.00

1. General information

1.1. Warnings, legal information and safety..................................................................................................5

1.1.1. Warnings and notes ......................................................................................................................5

1.1.2. Legal information and disclaimer ..................................................................................................5

1.1.3. Safety issues ................................................................................................................................5

1.1.4. Electrostatic discharge awareness ...............................................................................................5

1.1.5. Factory settings ............................................................................................................................6

1.2. About the designer's reference handbook..............................................................................................6

1.2.1. General purpose ...........................................................................................................................6

1.2.2. Intended users ..............................................................................................................................6

1.2.3. Contents and overall structure ......................................................................................................6

2. General product information

2.1. Introduction.............................................................................................................................................7

2.1.1. Introduction....................................................................................................................................7

2.2. Type of product......................................................................................................................................7

2.3. Options...................................................................................................................................................7

2.3.1. Options .........................................................................................................................................7

2.4. PC utility software warning.....................................................................................................................7

2.4.1. PC USW warning ..........................................................................................................................7

3. Passwords

3.1. Passwords and parameter access.........................................................................................................8

3.1.1. Password.......................................................................................................................................8

3.1.2. Parameter access..........................................................................................................................9

4. Functional descriptions

4.1. Standard functions...............................................................................................................................10

4.1.1. Standard functions ......................................................................................................................10

4.1.2. Operation modes.........................................................................................................................10

4.1.3. Engine control..............................................................................................................................10

4.1.4. Generator protection (ANSI) .......................................................................................................10

4.1.5. Busbar protection (ANSI) ............................................................................................................11

4.1.6. Display.........................................................................................................................................11

4.1.7. M-Logic........................................................................................................................................11

4.2. Terminal strip overview........................................................................................................................11

4.2.1. Reference to Installation Instructions...........................................................................................11

4.3. Measurement systems.........................................................................................................................11

4.3.1. Single phase system....................................................................................................................11

4.3.2. Split phase system.......................................................................................................................12

4.3.3. Three-phase system....................................................................................................................12

4.4. Applications..........................................................................................................................................13

4.4.1. Applications and genset modes...................................................................................................13

4.4.2. Application design........................................................................................................................13

4.4.3. AMF (no back synchronisation)...................................................................................................15

4.4.4. Island operation...........................................................................................................................16

4.4.5. Load takeover..............................................................................................................................16

4.5. Running mode description....................................................................................................................16

4.5.1. Manual mode...............................................................................................................................16

4.5.2. Test mode....................................................................................................................................17

4.5.3. Simple test...................................................................................................................................17

4.5.4. Full test........................................................................................................................................17

4.5.5. Block mode..................................................................................................................................18

4.6. Single-line diagrams.............................................................................................................................18

4.6.1. Application illustration .................................................................................................................18

4.6.2. Automatic Mains Failure..............................................................................................................19

4.6.3. Island operation...........................................................................................................................19

4.6.4. Load takeover..............................................................................................................................20

CGC 400 DRH 4189340786 UK

DEIF A/S Page 2 of 96

4.7. Flowcharts............................................................................................................................................20

4.7.1. Flowcharts...................................................................................................................................20

4.7.2. Mode shift....................................................................................................................................21

4.7.3. MB open sequence......................................................................................................................22

4.7.4. GB open sequence......................................................................................................................23

4.7.5. Stop sequence.............................................................................................................................24

4.7.6. Start sequence.............................................................................................................................25

4.7.7. MB close sequence.....................................................................................................................26

4.7.8. GB close sequence......................................................................................................................27

4.7.9. Load takeover..............................................................................................................................28

4.7.10. Island operation.........................................................................................................................29

4.7.11. Automatic Mains Failure, AMF...................................................................................................30

4.7.12. Test sequence...........................................................................................................................31

4.8. Sequences...........................................................................................................................................32

4.8.1. Sequences...................................................................................................................................32

4.8.2. Start sequence.............................................................................................................................33

4.8.3. Start sequence conditions...........................................................................................................34

4.8.4. Running feedback........................................................................................................................35

4.8.5. Stop sequence.............................................................................................................................38

4.8.6. Breaker sequences......................................................................................................................40

4.8.7. AMF timers..................................................................................................................................40

5. Display and menu structure

5.1. Reference to operator's manual...........................................................................................................43

6. Engine communication

6.1. Reference to H5 manual......................................................................................................................44

6.1.1. Engine communication ...............................................................................................................44

7. Additional functions

7.1. Start functions......................................................................................................................................45

7.1.1. Start functions..............................................................................................................................45

7.1.2. Digital feedbacks.........................................................................................................................45

7.1.3. Analogue tacho feedback............................................................................................................46

7.1.4. Oil pressure.................................................................................................................................47

7.2. Phase sequence error..........................................................................................................................49

7.2.1. Description of phase sequence error ..........................................................................................49

7.3. Breaker types.......................................................................................................................................49

7.3.1. Breaker types...............................................................................................................................49

7.4. Breaker spring load time......................................................................................................................49

7.4.1. Principle.......................................................................................................................................50

7.5. Alarm inhibit..........................................................................................................................................51

7.5.1. Run status (6160)........................................................................................................................53

7.6. Access lock..........................................................................................................................................54

7.7. Digital mains breaker control................................................................................................................56

7.8. Command timers..................................................................................................................................57

7.9. Running output.....................................................................................................................................58

7.10. Idle running.........................................................................................................................................59

7.10.1. Idle running................................................................................................................................59

7.10.2. Description.................................................................................................................................59

7.10.3. Examples...................................................................................................................................60

7.10.4. Inhibit.........................................................................................................................................61

7.10.5. Running signal...........................................................................................................................61

7.10.6. Idle speed flowcharts.................................................................................................................61

7.10.7. Start...........................................................................................................................................62

7.10.8. Stop...........................................................................................................................................63

7.11. Engine heater.....................................................................................................................................63

7.11.1. Engine heater alarm..................................................................................................................64

7.12. Ventilation...........................................................................................................................................64

CGC 400 DRH 4189340786 UK

DEIF A/S Page 3 of 96

7.12.1. Max. ventilation alarm................................................................................................................65

7.13. Not in auto..........................................................................................................................................65

7.14. Fuel pump logic..................................................................................................................................65

7.14.1. Fuel fill check.............................................................................................................................66

7.15. Fail class............................................................................................................................................67

7.15.1. Fail class....................................................................................................................................67

7.15.2. Engine running...........................................................................................................................67

7.15.3. Engine stopped..........................................................................................................................68

7.15.4. Fail class configuration..............................................................................................................68

7.16. Service timers.....................................................................................................................................69

7.17. Wire fail detection...............................................................................................................................70

7.18. Digital inputs.......................................................................................................................................71

7.18.1. Functional description................................................................................................................72

7.19. Outputs...............................................................................................................................................74

7.19.1. Functional description................................................................................................................75

7.20. Multi-inputs.........................................................................................................................................76

7.20.1. Multi-inputs................................................................................................................................76

7.20.2. 4-20 mA ....................................................................................................................................77

7.20.3. Pt100/Pt1000.............................................................................................................................77

7.20.4. RMI inputs..................................................................................................................................77

7.20.5. RMI oil........................................................................................................................................77

7.20.6. RMI water..................................................................................................................................78

7.20.7. RMI fuel.....................................................................................................................................79

7.20.8. Illustration of configurable inputs...............................................................................................80

7.20.9. Configuration.............................................................................................................................81

7.20.10. Scaling of 4-20 mA inputs........................................................................................................81

7.20.11. Binary ......................................................................................................................................83

7.21. Input function selection.......................................................................................................................83

7.22. Language selection............................................................................................................................84

7.22.1. Language selection ...................................................................................................................84

7.23. Text in status line...............................................................................................................................84

7.23.1. Standard texts............................................................................................................................85

7.24. Counters.............................................................................................................................................86

7.25. M-Logic...............................................................................................................................................87

7.26. Buzzer................................................................................................................................................87

7.26.1. Buzzer .......................................................................................................................................87

7.27. USW communication..........................................................................................................................87

7.27.1. USW communication ................................................................................................................87

7.28. Nominal settings.................................................................................................................................88

7.28.1. How to change the nominal settings..........................................................................................88

7.29. Scaling................................................................................................................................................88

7.30. Differential measurement...................................................................................................................89

7.30.1. Differential measurement...........................................................................................................89

7.31. Filename extension............................................................................................................................91

7.31.1. Filename extension ...................................................................................................................91

7.32. Modbus parameters...........................................................................................................................91

7.32.1. Modbus parameters ..................................................................................................................91

7.33. Battery low voltage alarm timer..........................................................................................................91

7.33.1. Battery low voltage alarm timer ................................................................................................91

8. Protections

8.1. General.................................................................................................................................................93

8.1.1. General........................................................................................................................................93

8.2. Voltage-dependent (restraint) overcurrent...........................................................................................95

9. Parameter list

9.1. Related parameters..............................................................................................................................96

9.1.1. Related parameters ....................................................................................................................96

CGC 400 DRH 4189340786 UK

DEIF A/S Page 4 of 96

1. General information

1.1 Warnings, legal information and safety

1.1.1 Warnings and notes

Throughout this document, a number of warnings and notes with helpful user information will be presented.

To ensure that these are noticed, they will be highlighted as follows in order to separate them from the gener-

al text.

Warnings

Warnings indicate a potentially dangerous situation, which could result in death, personal in-

jury or damaged equipment, if certain guidelines are not followed.

Notes

Notes provide general information, which will be helpful for the reader to bear in mind.

1.1.2 Legal information and disclaimer

DEIF takes no responsibility for installation or operation of the generator set. If there is any doubt about how

to install or operate the engine/generator controlled by the unit, the company responsible for the installation or

the operation of the set must be contacted.

The unit is not to be opened by unauthorised personnel. If opened anyway, the warranty will be

lost.

Disclaimer

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

1.1.3 Safety issues

Installing and operating the unit may imply work with dangerous currents and voltages. Therefore, the instal-

lation should only be carried out by authorised personnel who understand the risks involved in working with

live electrical equipment.

Be aware of the hazardous live currents and voltages. Do not touch any AC measurement in-

puts as this could lead to injury or death.

DEIF do not recommend to use the USB as the primary power supply for the unit.

1.1.4 Electrostatic discharge awareness

Sufficient care must be taken to protect the terminal against static discharges during the installation. Once the

unit is installed and connected, these precautions are no longer necessary.

CGC 400 DRH 4189340786 UK General information

DEIF A/S Page 5 of 96

1.1.5 Factory settings

The unit is delivered from factory with certain factory settings. These are based on average values and are

not necessarily the correct settings for matching the engine/generator set in question. Precautions must be

taken to check the settings before running the engine/generator set.

1.2 About the designer's reference handbook

1.2.1 General purpose

This Designer's Reference Handbook mainly includes functional descriptions, presentation of display unit and

menu structure, the procedure for parameter setup and reference to parameter lists.

The general purpose of this document is to provide useful overall information about the functionality of the

controlelr and its applications. This document also offers the user the information he needs in order to suc-

cessfully set up the parameters needed in his specific application.

Please make sure to read this document before starting to work with the controller and the

genset to be controlled. Failure to do this could result in human injury or damage to the equip-

ment.

1.2.2 Intended users

This Designer's Reference Handbook is mainly intended for the panel builder designer in charge. On the ba-

sis of this document, the panel builder designer will give the electrician the information he needs in order to

install the unit, e.g. detailed electrical drawings. In some cases, the electrician may use these installation in-

structions himself.

1.2.3 Contents and overall structure

This document is divided into chapters, and in order to make the structure simple and easy to use, each

chapter will begin from the top of a new page.

CGC 400 DRH 4189340786 UK General information

DEIF A/S Page 6 of 96

2. General product information

2.1 Introduction

2.1.1 Introduction

This chapter will deal with the unit in general and its place in the DEIF product range.

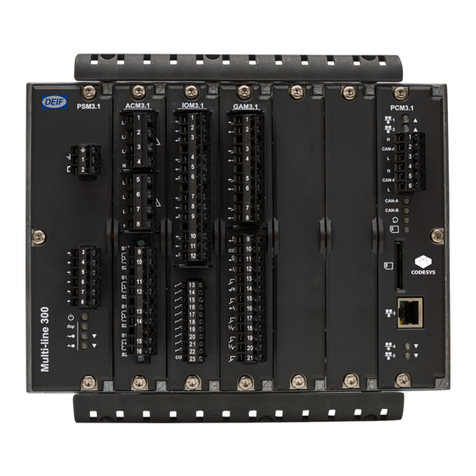

The CGC, short for Compact Genset Controller, is part of the DEIF Compact Genset Controller range, based

on standard advanced software of Multi-line 2. The concept of the CGC is to offer a cost-effective solution to

genset builders, who need a flexible generator protection and control unit for small single to medium and

large genset applications.

2.2 Type of product

The compact genset controller is a micro-processor based control unit containing all necessary functions for

protection and control of a genset.

It contains all necessary 3-phase measuring circuits, and all values and alarms are presented on the LCD

display.

The CGC 400 will come in two different variants: CGC 412 and CGC 413.

The CGC 412 is the unit that is able to perform auto start, and the CGC 413 is able to make the automatic

mains failure (AMF) sequences. The hardware for the two products is different, therefore some of the sequen-

ces described in this document are only relevant to one of the variants. You will find a detailed description of

the available functions in each product in the chapter "Standard Functions".

For detailed specifications of the hardware, please refer to the datasheet.

2.3 Options

2.3.1 Options

When ordering the CGC 400, it comes with a number of features, which were options in the other DEIF prod-

ucts.

The customer cannot add or remove any of these features/options.

The included features are A1, C2, H2, H5.

2.4 PC utility software warning

2.4.1 PC USW warning

It is possible to remote-control the genset from the PC utility software or AGI. To avoid person-

al injury, make sure that it is safe to remote-control the genset.

DEIF do not recommend to use the USB as the primary power supply for the unit.

CGC 400 DRH 4189340786 UK General product information

DEIF A/S Page 7 of 96

3. Passwords

3.1 Passwords and parameter access

3.1.1 Password

The unit includes three password levels. All levels can be adjusted in the PC software.

Available password levels:

Password level Factory setting Access

Customer Service Master

Customer 2000 X

Service 2001 X X

Master 2002 X X X

A parameter cannot be entered with a password that is ranking too low. But the settings can be displayed

without password entry.

Each parameter can be protected by a specific password level. To do so, the PC utility software must be

used. Enter the parameter to be configured and select the correct password level.

CGC 400 DRH 4189340786 UK Passwords

DEIF A/S Page 8 of 96

The password level can also be changed from the parameter view in the column "Level".

3.1.2 Parameter access

To gain access to adjust the parameters, the password level must be entered:

If the password level is not entered, it is not possible to enter the parameters.

The customer password can be changed in jump menu 9116. The service password can be

changed in jump menu 9117. The master password can be changed in jump menu 9118.

The factory passwords must be changed if the operator of the genset is not allowed to change

the parameters.

It is not possible to change the password at a higher level than the password entered.

CGC 400 DRH 4189340786 UK Passwords

DEIF A/S Page 9 of 96

4. Functional descriptions

4.1 Standard functions

4.1.1 Standard functions

This section includes functional descriptions of standard functions as well as illustrations of the relevant appli-

cation types. Flowcharts and single-line diagrams will be used in order to simplify the information.

The standard functions are listed in the following paragraphs.

The table below describes the genset modes that are available, depending on the variant of the CGC to be

used.

Application Comment

Automatic Mains Failure (AMF) (no back sync.) CGC 413

Island operation CGC 412/CGC 413

Load takeover CGC 413

On the hardware point of view, the CGC 412 has a lighter specification than the CGC 413.

The table below describes which points differ from each other.

Feature (terminal numbers) Available on CGC 412 Available on CGC 413

Mains measurement (term. 28 to 32) No Yes

Extra multi-inputs (term. 58 and 59) No Yes

Extra binary inputs (term. 56 and 57) No Yes

4.1.2 Operation modes

● Automatic Mains Failure

● Island operation

● Load takeover

4.1.3 Engine control

● Start/stop sequences

● Run and stop coil

4.1.4 Generator protection (ANSI)

● 2 x reverse power (32)

● 5 x overload (32)

● 4 x overcurrent (50/51)

● 2 x overvoltage (59)

● 3 x undervoltage (27)

● 3 x over-/underfrequency (81)

● Multi-inputs (digital, 4-20 mA, Pt100, Pt1000 or RMI)

● Digital inputs

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 10 of 96

The overcurrent level is limited to 200% of the nominal current. Therefore, it cannot be consid-

ered as a short-circuit protection.

4.1.5 Busbar protection (ANSI)

● 2 x over-voltage (59)

● 2 x under-voltage (27)

● 2 x over-frequency (81)

● 2 x under-frequency (81)

4.1.6 Display

● Push-buttons for start and stop

● Push-buttons for breaker operations

● Status texts

4.1.7 M-Logic

● Simple logic configuration tool

● Selectable input events

● Selectable output commands

4.2 Terminal strip overview

4.2.1 Reference to Installation Instructions

Please see the Installation Instructions for terminal strip overview and rear side controller view.

4.3 Measurement systems

The CGC 400 is designed for measurement of voltages between 100 and 480V AC. For further reference, the

AC wiring diagrams are shown in the Installation Instructions. In menu 9130, the measurement principle can

be changed between three-phase, single phase and split phase.

Configure the CGC 400 to match the correct measuring system. When in doubt, contact the

switchboard manufacturer for information about the required adjustment.

4.3.1 Single phase system

The single phase system consists of one phase and the neutral.

The following adjustments must be made to make the system ready for the single phase measuring (example

230V AC):

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 11 of 96

Setting Adjustment Description Adjust to

value

6004 G nom. voltage Phase-neutral voltage of the generator 230V AC

6041 G transformer Primary voltage of the G voltage transformer (if installed) UNOM x √3

6042 G transformer Secondary voltage of the G voltage transformer (if installed) UNOM x √3

6051 BB transformer Primary voltage of the BB voltage transformer (if installed) UNOM x √3

6052 BB transformer Secondary voltage of the BB voltage transformer (if installed) UNOM x √3

6053 BB nom. voltage Phase-phase voltage of the busbar UNOM x √3

The voltage alarms refer to UNOM (230V AC).

The controller has two sets of BB transformer settings, which can be enabled individually in

this measurement system.

4.3.2 Split phase system

This is a special application where two phases and neutral are connected to the controller. The controller

shows phases L1 and L3 in the display. The phase angle between L1 and L3 is 180 degrees. Split phase is

possible between L1-L2 or L1-L3.

The following adjustments must be made to make the system ready for the split phase measuring (example

240/120V AC):

Setting Adjustment Description Adjust to

value

6004 G nom. voltage Phase-phase voltage of the generator 120V AC

6041 G transformer Primary voltage of the G voltage transformer (if installed) UNOM

6042 G transformer Secondary voltage of the G voltage transformer (if installed) UNOM

6051 BB transformer Primary voltage of the BB voltage transformer (if installed) UNOM

6052 BB transformer Secondary voltage of the BB voltage transformer (if installed) UNOM

6053 BB nom. voltage Phase-phase voltage of the busbar UNOM

The measurement UL3L1 shows 240V AC. The voltage alarm setpoints refer to the nominal volt-

age 120V AC, and UL3L1 does not activate any alarm.

The controller has two sets of BB transformer settings, which can be enabled individually in

this measurement system.

4.3.3 Three-phase system

When the controller is delivered from the factory, the three-phase system is selected. When this principle is

used, all three phases must be connected to the controller.

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 12 of 96

The following adjustments must be made to make the system ready for the three-phase measuring (example

400/230V AC):

Setting Adjustment Description Adjust to

value

6004 G nom. voltage Phase-phase voltage of the generator 400V AC

6041 G transformer Primary voltage of the G voltage transformer (if installed) UNOM

6042 G transformer Secondary voltage of the G voltage transformer (if installed) UNOM

6051 BB transformer Primary voltage of the BB voltage transformer (if installed) UNOM

6052 BB transformer Secondary voltage of the BB voltage transformer (if installed) UNOM

6053 BB nom. voltage Phase-phase voltage of the busbar UNOM

The controller has two sets of BB transformer settings, which can be enabled individually in

this measurement system.

4.4 Applications

4.4.1 Applications and genset modes

This section about applications is to be used for reference using the particular genset mode as

starting point. It is not suitable for reading from beginning to end.

The unit can be used for the applications listed in the table below.

Application Comment

Automatic Mains Failure (no back sync.) CGC 413

Island operation CGC 412/CGC 413

Load takeover CGC 413

Genset mode Running mode

Auto Test Man Block

Automatic Mains Failure (no back sync.) X X X X

Island operation X X X X

Load takeover X X X X

For a general description of the available running modes, please refer to the chapter "Running

mode description".

4.4.2 Application design

The application is designed through the utility software. Please select configuration.

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 13 of 96

Select a new application and adjust the settings in this dialogue box.

The product will be automatically selected if you are currently connected to the unit when doing this configu-

ration.

When using the CGC 400, the plant type will be stuck to "Single DG". This means no CAN communication

can be established with other units.

The active choice we can make here is the name of the application.

Using the CGC 400, only one application will be available.

Now the application can be designed using the section control panel.

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 14 of 96

For each area, it is defined whether a generator and a mains are present, and the number and type of break-

ers.

If a CGC 412 is currently connected, it will not be possible to draw an application with a mains or a mains

breaker.

This application configuration setup is here to give the user the choice of which breaker type is in use.

It will be possible to choose between "Pulse", "Continuous NE" or "Compact" for the generator breaker.

For the mains breaker, in case a CGC 413 is connected, the choice will be between "Pulse", "Continuous

NE", "Continuous ND" or "Compact".

4.4.3 AMF (no back synchronisation)

Auto mode description

The unit automatically starts the genset and switches to generator supply at a mains failure after an adjusta-

ble delay time. It is possible to adjust the unit to change to genset operation in two different ways:

1. The mains breaker will be opened at genset start-up.

2. The mains breaker will remain closed until the genset is running, and the genset voltage and frequency is

OK.

In both cases, the generator breaker will be closed when the generator voltage and frequency is OK, and the

mains breaker is open.

When the mains returns, the unit will switch back to mains supply and cool down and stop the genset. The

switching back to mains supply is done when the adjusted "Mains OK delay" has expired.

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 15 of 96

For a general description of the available running modes, please refer to the chapter "Running

mode description".

4.4.4 Island operation

Auto mode description

The unit automatically starts the genset and closes the generator breaker at a digital start command. When

the stop command is given, the generator breaker is tripped, and the genset will be stopped after a cooling

down period. The start and stop commands are used by activating and deactivating a digital input or with the

time-dependent start/stop commands. If the time-dependent start/stop commands are to be used, the auto

mode must also be used.

For a general description of the available running modes, please refer to the chapter "Running

mode description".

4.4.5 Load takeover

Auto mode description

The purpose of the load takeover mode is to transfer the load imported from the mains to the genset for oper-

ation on generator supply

The unit automatically starts the genset and closes the generator breaker at a digital start command. When

the stop command is given, the generator breaker is tripped, and the genset will be stopped after a cooling-

down period. The start and stop commands are used by activating and deactivating a digital input or with the

time-dependent start/stop commands. If the time-dependent start/stop commands are to be used, then the

auto mode must also be used.

4.5 Running mode description

4.5.1 Manual mode

The unit can be operated in manual mode (MAN). Manual means that the unit will not initiate any sequences

automatically, as is the case with the auto mode. It will only initiate sequences, if external signals are given.

An external signal may be given in three ways:

1. Display push-buttons

2. Digital inputs

3. Modbus command at service port or RS485

The standard CGC 400 is only equipped with a limited number of digital inputs, please refer to

"Digital inputs" in this document and the data sheet for additional information about availabili-

ty.

The following sequences can be activated in manual mode:

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 16 of 96

Command Description Comment

Start The start sequence is initiated and continues until the genset starts or the

maximum number of start attempts has been reached. If Hz/V OK the GB

is ready to close.

Stop The genset will be stopped. After disappearance of the running signal, the

stop sequence will continue to be active in the ‘"extended stop time" peri-

od. The genset is stopped with cooling down time.

The cooling

down time is

cancelled if the

stop button is

activated twice.

Close GB The unit will close the generator breaker if the mains breaker is open

Open GB The unit will open the generator breaker instantly

Close MB The unit will close the mains breaker if the generator breaker is open

Open MB The unit opens the mains breaker instantly.

4.5.2 Test mode

The test mode function is activated by activating a digital input, Modbus RS485, USW or the TEST push-but-

ton on the display.

The settings for the test function are set up in menu

7040 Test

● Timer: Period starts when U/f is ok. Engine stops when time runs out.

● Return: When the test is completed, the unit will return to the selected mode (manual or auto).

● Type: Selection of one of the two types of tests: simple or full.

If the timer in parameter 7042 is set to 0.0 min., the test sequence will be infinite. The test will

be cancelled by pushing TEST again.

The test will be interrupted if the mode is changed to either manual or auto.

4.5.3 Simple test

The controller will go through the start sequence and run the engine for the time set in parameter 7042 with-

out any breaker operation. This sequence is initiated by a digital input or the TEST push-button on the front.

The test will run until the timer expires. When the timer runs out, the stop sequence including cooling down

will be carried out.

4.5.4 Full test

The full test will start the genset, open the mains breaker, if pressent, and close the generator breaker. When

the test timer expires or the test is cancelled by mode change, the generator breaker is opened, the mains

breaker closed, if pressent, and the generator is stopped after the cooldown time.

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 17 of 96

It is possible to open and close the generator breaker and the mains breaker in manual mode.

4.5.5 Block mode

Block mode can be enabled by pressing the MAN button twice, with M-Logic or a digital input. When block

mode is selected, the controller will be locked for certain actions. This means that it cannot start the genset or

perform any breaker operations from the buttons.

The purpose of the block mode is to make sure that the genset does not start for instance during mainte-

nance work.

It is important to know that the digital input configured to block mode is a constant signal. So,

when it is ON, the unit is in a blocked state, and when it is OFF, it returns to the mode it was in

before block mode was selected.

When controller goes into block mode, it will:

● Open GB, shut down the engine, show "BLOCK" in the display and flash the MAN LED

● GB ON, GB OFF, MB ON, MB OFF and START buttons are locked

If block mode is selected using the display, the block mode can only be deactivated from the display. If block

mode is selected using the digital input, the block mode can only be deactivated by setting the digital input to

OFF.

Before the running mode is changed, it is important to check that persons are clear of the gen-

set and that the genset is ready for operation.

Alarms are not influenced by block mode selection.

The genset can be started from the local engine control panel, if such is installed. Therefore,

DEIF recommends avoiding local cranking and starting of the genset.

The genset will shut down if block mode is selected while the genset is running.

4.6 Single-line diagrams

4.6.1 Application illustration

In the following, the various applications are illustrated in single-line diagrams.

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 18 of 96

4.6.2 Automatic Mains Failure

G

Controller

Load

4.6.3 Island operation

G

Controller

Load

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 19 of 96

4.6.4 Load takeover

G

Controller

Load

4.7 Flowcharts

4.7.1 Flowcharts

Using flowcharts, the principles of the most important functions will be illustrated in the next sections. The

functions included are:

● Mode shift

● MB open sequence

● GB open sequence

● Stop sequence

● Start sequence

● MB close sequence

● GB close sequence

● Load takeover

● Island operation

● Automatic Mains Failure

● Test sequence

The flowcharts on the following pages are for guidance only. For illustrative purposes, the

flowcharts are simplified in some extent.

CGC 400 DRH 4189340786 UK Functional descriptions

DEIF A/S Page 20 of 96

Other manuals for CGC 400

3

Table of contents

Other Deif Controllers manuals

Deif

Deif AGC 200 Series User manual

Deif

Deif SGC 421 User manual

Deif

Deif 4189340315C User manual

Deif

Deif Multi-line 2 User manual

Deif

Deif SGC 120 User manual

Deif

Deif AGC 150 User manual

Deif

Deif AGC-4 User manual

Deif

Deif AGC 150 User manual

Deif

Deif SGC 410 User manual

Deif

Deif DVC 310 Installation and operation manual