pRack +040000071 rel. 1.1 - 14.10.2011

3

ENG

IMPORTANT

CAREL bases the development of its products on decades of experience

in HVAC, on the continuous investments in technological innovations

to products, procedures and strict quality processes with in-circuit

and functional testing on 100% of its products, and on the most

innovative production technology available on the market. CAREL and

its subsidiaries nonetheless cannot guarantee that all the aspects of

the product and the software included with the product respond to

the requirements of the final application, despite the product being

developed according to start-of-the-art techniques. The customer

(manufacturer, developer or installer of the final equipment) accepts

all liability and risk relating to the configuration of the product in order

to reach the expected results in relation to the specific final installation

and/or equipment. CAREL may, based on specific agreements, act as a

consultant for the positive commissioning of the final unit/application,

however in no case does it accept liability for the correct operation of

the final equipment/system.

The CAREL product is a state-of-the-art product, whose operation is

specified in the technical documentation supplied with the product or

can be downloaded, even prior to purchase, from the website www.

CAREL.com.

Each CAREL product, in relation to its advanced level of technology,

requires setup / configuration / programming / commissioning to be

able to operate in the best possible way for the specific application. The

failure to complete such operations, which are required/indicated in the

user manual, may cause the final product to malfunction; CAREL accepts

no liability in such cases.

Only qualified personnel may install or carry out technical service on

the product.

The customer must only use the product in the manner described in the

documentation relating to the product.

In addition to observing any further warnings described in this manual,

the following warnings must be heeded for all CAREL products:

• Prevent the electronic circuits from getting wet. Rain, humidity

and all types of liquids or condensate contain corrosive minerals

that may damage the electronic circuits. In any case, the product

should be used or stored in environments that comply with the

temperature and humidity limits specified in the manual.

• Do not install the device in particularly hot environments. Too

high temperatures may reduce the life of electronic devices,

damage them and deform or melt the plastic parts. In any case,

the product should be used or stored in environments that

comply with the temperature and humidity limits specified in

the manual.

• Do not attempt to open the device in any way other than

described in the manual.

• Do not drop, hit or shake the device, as the internal circuits and

mechanisms may be irreparably damaged.

• Do not use corrosive chemicals, solvents or aggressive

detergents to clean the device.

• Do not use the product for applications other than those

specified in the technical manual.

All of the above suggestions likewise apply to the controllers, serial

boards, programming keys or any other accessory in the CAREL product

portfolio.

CAREL adopts a policy of continual development. Consequently, CAREL

reserves the right to make changes and improvements to any product

described in this document without prior warning.

The technical specifications shown in the manual may be changed

without prior warning.

The liability of CAREL in relation to its products is specified in the

CAREL general contract conditions, available on the website www.

CAREL.com and/or by specific agreements with customers; specifically,

to the extent where allowed by applicable legislation, in no case will

CAREL, its employees or subsidiaries be liable for any lost earnings or

sales, losses of data and information, costs of replacement goods or

services, damage to things or people, downtime or any direct, indirect,

incidental, actual, punitive, exemplary, special or consequential damage

of any kind whatsoever, whether contractual, extra-contractual or due

to negligence, or any other liabilities deriving from the installation, use

or impossibility to use the product, even if CAREL or its subsidiaries are

warned of the possibility of such damage.

DISPOSAL

INFORMATION FOR USERS ON THE CORRECT HANDLING OF WASTE

ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE)

In reference to European Union directive 2002/96/EC issued on 27

January 2003 and the related national legislation, please note that:

• WEEE cannot be disposed of as municipal waste and such waste

must be collected and disposed of separately;

• the public or private waste collection systems defined by local

legislation must be used. In addition, the equipment can be

returned to the distributor at the end of its working life when

buying new equipment;

• the equipment may contain hazardous substances: the improper

use or incorrect disposal of such may have negative effects on

human health and on the environment;

• the symbol (crossed-out wheeled bin) shown on the product or

on the packaging and on the instruction sheet indicates that the

equipment has been introduced onto the market after 13 August

2005 and that it must be disposed of separately;

• in the event of illegal disposal of electrical and electronic waste,

the penalties are specified by local waste disposal legislation.

Warranty on the materials: 2 years (from the date of production,

excluding consumables).

Approval: the quality and safety of CAREL INDUSTRIES Hqs products

are guaranteed by the ISO 9001 certified design and production system.

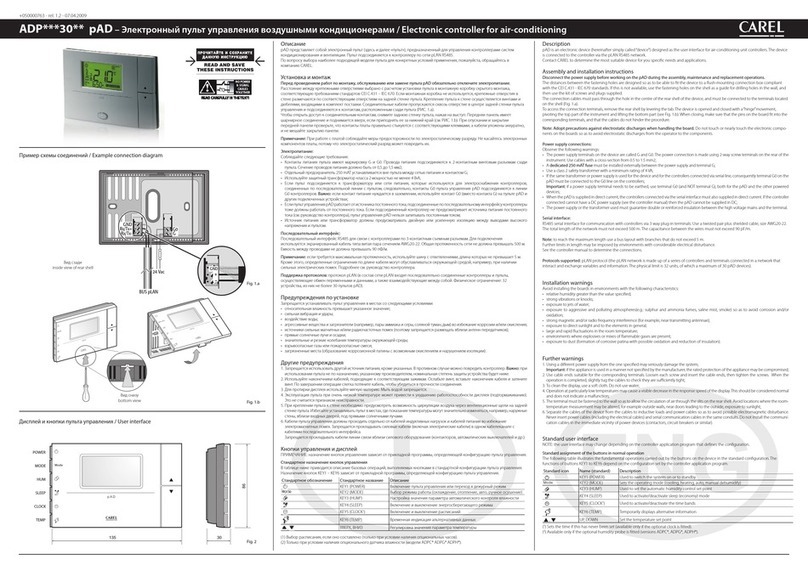

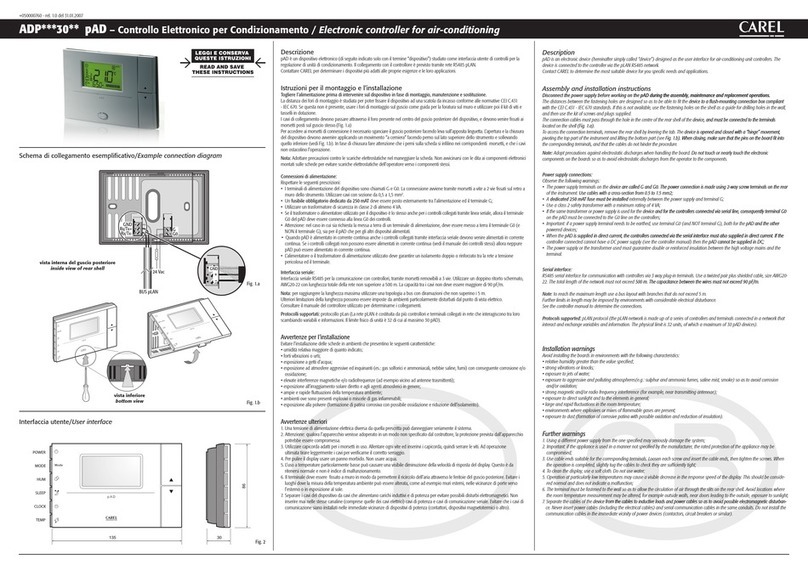

WARNING: separate as much as possible the probe and digital input

signal cables from the cables carrying inductive loads and power cables

to avoid possible electromagnetic disturbance. Never run power cables

(including the electrical panel wiring) and signal cables in the same

conduits.

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

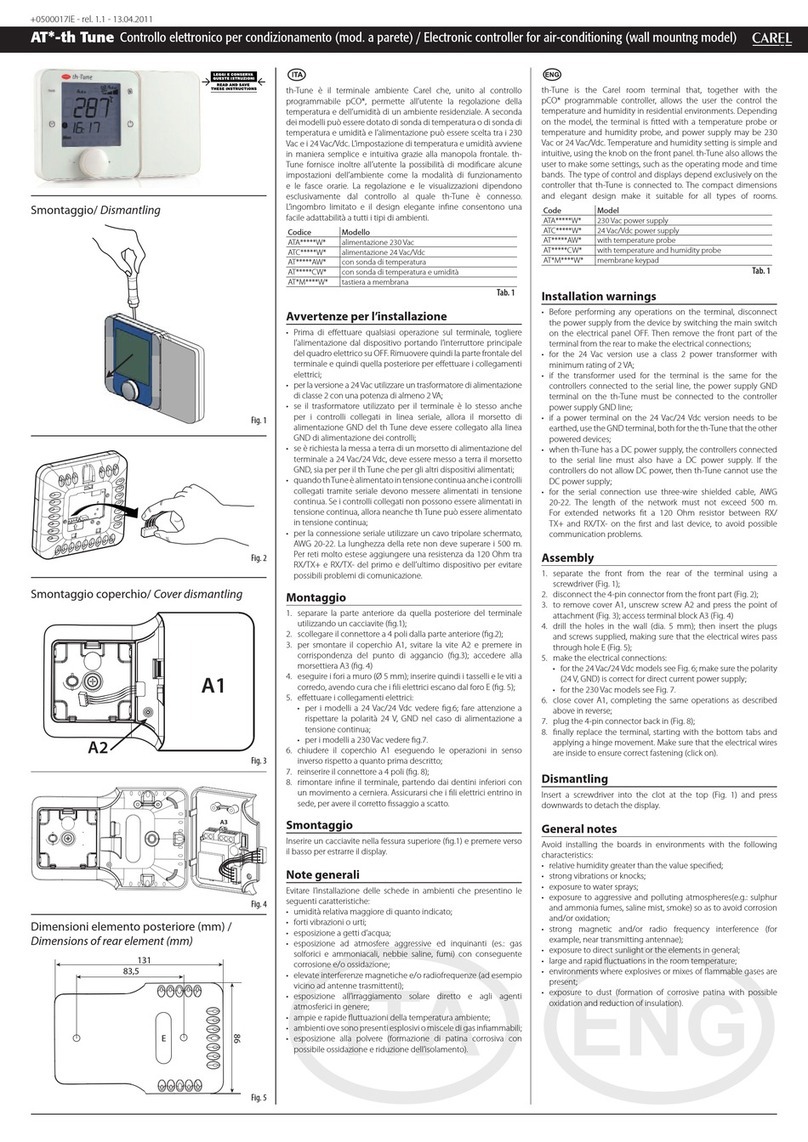

Key icone

NOTE: to bring attention to a very important

subject; in particular, regarding the

practical use of the various functions of

the product.

IMPORTANT: to bring critical issues regarding the use

of the pRack PR100 to the attention of

the user.

TUTORIAL: some simple examples to accompany

the user in configuring the most common

settings.