1WARNINGS

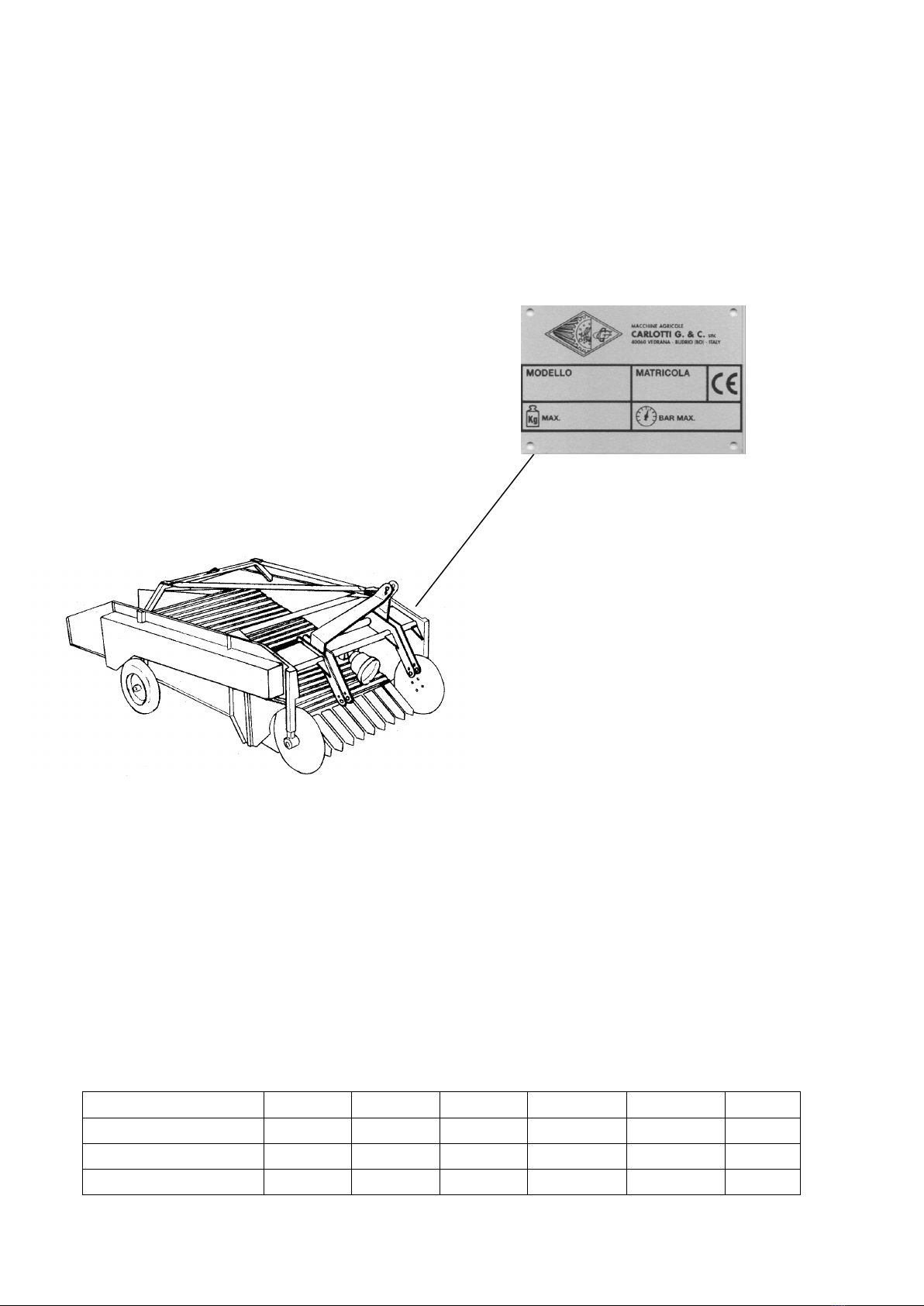

The target of this handbook is to provide the operator useful information on how

safety use and maintain the implement.

Before using the potato digger KMC, it is necessary to read carefully this use and

maintenance handbook.

After having read this handbook, please keep it and consult it each time any doubt

should arise.

All documents are considered as an essential part to the machine and have to

be carefully kept during its service life. Should the documentation get lost,

please apply directly to the Manufacturer for an additional copy.

1.1 Safety rules

To avoid an accident, it is important to recognise and understand possible dangerous

situations!

1- It is recommended to familiarise with this handbook as well as the digger itself,

before manipulating and using it. While doing it, special attention should be paid to

the working of particular mechanisms, their regulation and proper adjustment.

2- Before and while working it is recommended to NOT have any alcoholic drink,

medicine or other, which could alter physical and mental capabilities.

3- Before getting to work, the digger and the tractor efficiency should be checked out.

Before setting the digger in motion, it should be also checked if there is any people

around.

4- Speed should be adequately limited and precautions taken while turning and going

up.

5- Soon after having finished the work and during breaks, the digger should be

lowered to the ground and detached from the tractor.

6- Connection to the tractor should be done with extreme caution.

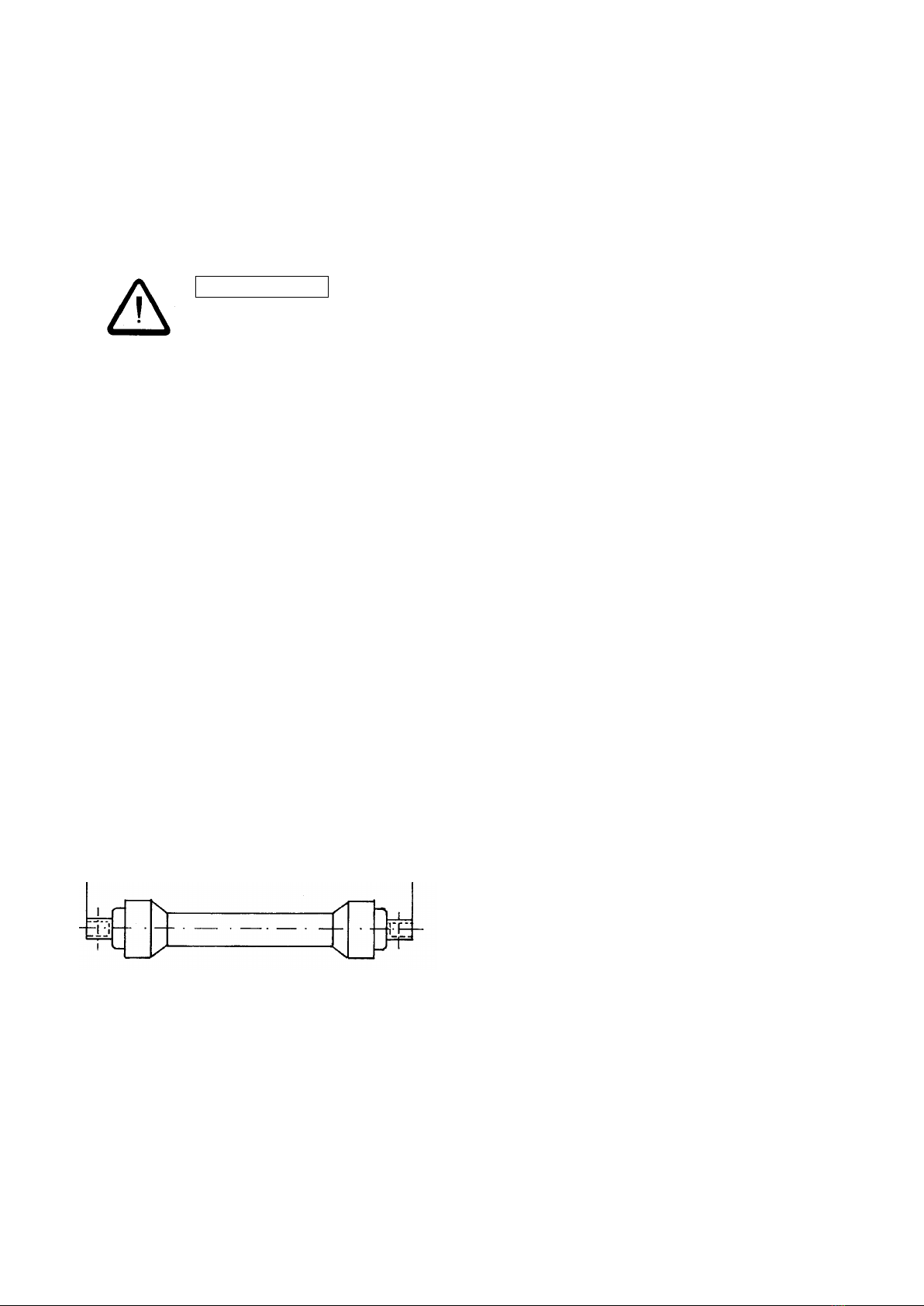

7- Repairs, regulations, cleaning, maintenance, technological disturbances removal

ought to be made with the digger and the tractor NOT connected.

Most of the accidents at work are due to non-observance of the basic

precautions of safety.

Many accidents happen while moving the group tractor-machine on the road

and in the farm.

It is forbidden:

To use the digger without having read this handbook attentively.

To lubricate, adjust or repair the digger while it is connected to the tractor.

To use the digger or a tractor which are not efficient.