3

1. Introduction................................................................................................................................4

1.1. Safety symbols and inscriptions ...........................................................................................5

2. General information....................................................................................................................7

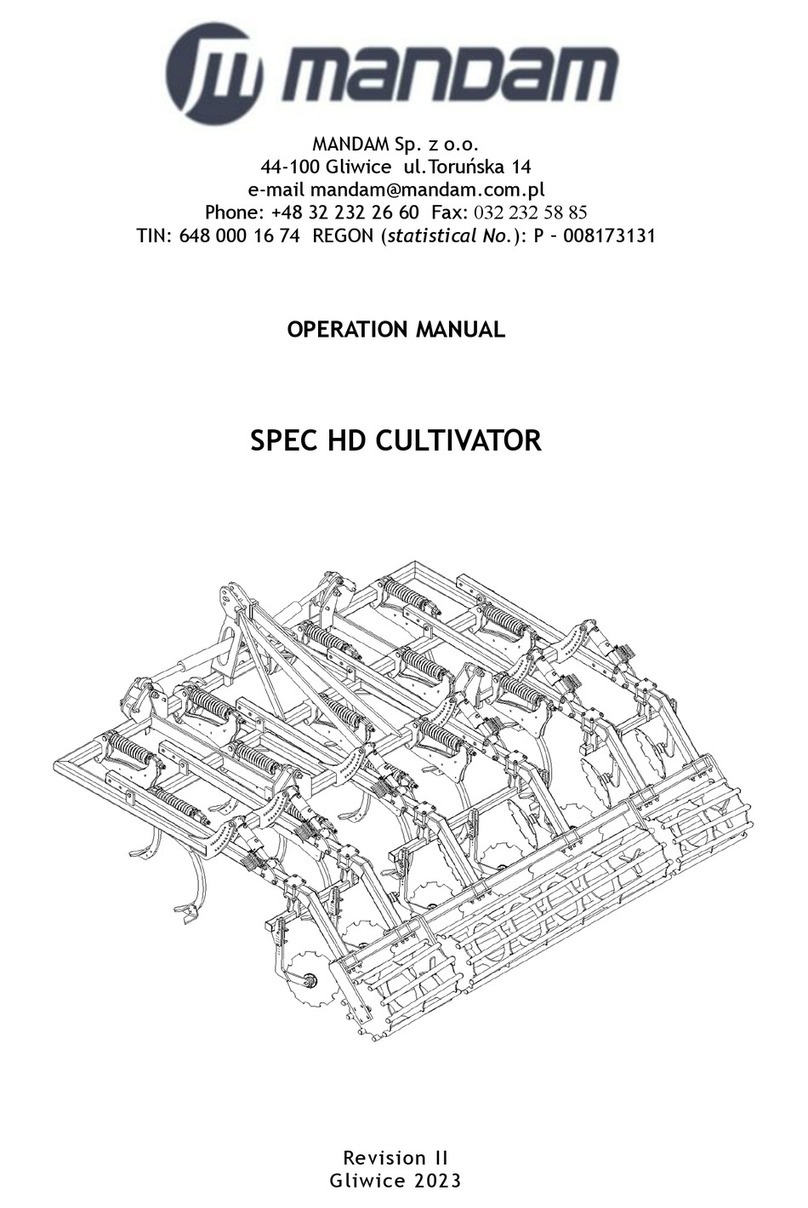

2.1. Design of the SUPER cultivator.........................................................................................7

2.2. Intended use .........................................................................................................................8

3. General safety information .......................................................................................................8

3.1. Proper hitching and unhitching the cultivator from the tractor ........................................9

3.2. Hydraulic system ..................................................................................................................9

3.3. Transport safety on public roads..........................................................................................9

3.4. Residual risk description ....................................................................................................10

3.5. Residual risk assessment ....................................................................................................10

4. Information on operation and use ..........................................................................................10

4.1. Before using the cultivator.................................................................................................12

4.2. Hitching the cultivator with the tractor .............................................................................13

4.3. Operation and adjustment..................................................................................................13

4.3.1. Automatic locking of the machine side extensions ......................................................14

4.3.2. Implement opening sequence ........................................................................................14

4.3.3. SUPER cultivator working depth.................................................................................16

4.4. Rules for transporting the cultivator on public roads and lighting the implement .........19

4.5. Maintenance and lubrication.............................................................................................20

4.6. Screw tightening torque .....................................................................................................20

5. SUPER cultivator maintenance ..............................................................................................21

5.1. Hydraulic system maintenance ..........................................................................................22

6. Replacement procedures .........................................................................................................22

7. SUPER cultivator storage........................................................................................................23

8. SUPER cultivator – spare parts..............................................................................................24