Fork farms FLEX FARM User manual

Copyright © 2020 Fork Farms, All Rights Reserved

FLEX FARM

ASSEMBLY MANUAL

1

TABLE OF CONTENTS

Section 1

Introduction and Safety

Introduction........................................................................................................................................... 3

Safety First ..............................................................................................................................................4

Warranty Information ..................................................................................................................... 5

Returns...................................................................................................................................................... 5

Shipping................................................................................................................................................... 5

Contact Us............................................................................................................................................... 5

Unpack and Inspect ........................................................................................................................6

Section 2

Flex Farm Assembly

Assemble Caster Unit .....................................................................................................................11

Assemble Tanks & Pump .............................................................................................................12

Assemble Root Chambers & Panels.................................................................................... 16

Add Light Tower............................................................................................................................... 20

Set Aside Remaining Parts.......................................................................................................20

Assembly Complete ........................................................................................................................21

2

3 3

SECTION 1

INTRODUCTION AND SAFETY

Fork Farms is an indoor agriculture

technology company that partners

with people and communities to make

the process of producing healthy food

accessible to the world.

We believe that when people have the

right tools and knowledge, they will feel

empowered, happier and healthier.

We are excited to have you join our

movement to close the gap between

people and the nourishment they

depend on.

Fresh food awaits!

Understand Your Flex Farm

Your Flex Farm is a fully self-contained, indoor hydroponic growing system. Hydroponics is the

practice of growing without soil. Instead, you add nutrients directly to the water supply to feed

the plants. As water runs down the panels to wet the roots, the plants will pull the nutrients

right from the water.

45X

More produce

production

97%

Less water

required

40%

More energy

efficient

ZERO

Food miles

and waste

Flex Farm vs.

Traditional Agriculture

vs. Hydroponic

Competitors

4

Safety First

Be aware that the Flex Farm uses water and electricity, so there is a risk of electric shock if

instructions are not followed carefully. Also, some of the materials used are caustic and should

be kept out of the reach of children.

Your Flex Farm is equipped with safety features. Its in-line GFCI protection ensures that if

water ever meets the light tower, no one will get hurt. The water tank is designed to prevent

leaks and protect your oor.

We recommend using food safety gloves when handling plants. If you touch anything other

than plants with the gloves, you should re-glove before handling plants again.

Visit the Fork Farms website (www.forkfarms.com/growing-resources/) for commercial food

safety tools and resources. Fork Farms recommends following standard food safety practices

to farms of all sizes.

Always pay special attention to the safety notices included in this manual.

NOTICE is used to address practices not related to

physical injury, which, if not avoided, could cause

damage to the Flex Farm or surrounding property.

Notice

CAUTION indicates a hazardous situation which, if

not avoided, could result in minor or moderate injury.

Caution

WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

Warning

Section 1Introduction & Safety

5

Warranty Information

Fork Farms backs all Flex Farms with a one-year parts warranty against manufacturing

defects or failure, not due to misuse or error in operation. Should any part fail within one

year of purchase as a result of a manufacturing defect or failure not due to misuse or error

in operation, Fork Farms will replace that part free of charge. Any modications to the Flex

Farm or allowing water to fall below the top of the pump will void the warranty.

Returns

Fork Farms offers a 14-day return policy on all Flex Farms. Returns must be initiated within 14

calendar days from the date the order was placed. To be eligible for a return, your Flex Farm

must be unopened, unused and in the same condition that you received it. Your item must

be in the original packaging. A receipt or proof of purchase is also required.

Shipping

You will be responsible for paying your own shipping costs for returning your item. Shipping

costs are nonrefundable. If you receive a refund, the cost of return shipping will be deducted

from your refund.

Contact Us

If you have any questions about warranties or returns, please contact Fork Farms at:

Introduction & SafetySection 1

6

Choose Farm Placement

Your Flex Farm is a fully self-contained

hydroponic growing system. Flex Farms

work great in classrooms, front lobbies,

cafeterias, homes and many more locations!

Carefully read and follow the instructions

in this section.

Congratulations! Your Flex Farm has arrived!

SECTION 2

FLEX FARM ASSEMBLY

If you make changes to the Flex Farm, you will void

the one-year limited warranty.

Notice

For quick and easy assembly

instructions, visit the Fork Farms

website to view our Flex Farm

Assembly Video.

(www.forkfarms.com/ex-farm-assembly/)

7

Flex Farm AssemblySection 2

Prepare Location

The location selected for the Flex Farm must

meet the following requirements:

• Temperature-controlled area

(ideally 68°F to 75°F)

• Standard ceiling (at least 7 ft)

• Accessible water source (e.g. sink)

• Floor space that supports at least 325 pounds

and is large enough for the Flex Farm to open

and span to 3 ft x 6 ft

• Direct access to a grounded (three prong) 120V

electrical outlet

NOTE: Be sure to place the Flex Farm in an area

where people will regularly see it, as that’s the

easiest way to remember to work on it. The Flex

Farm is easy to use, but needs to be monitored.

Clear the area to allow room to work.

Unpack and Inspect

1. Unpack the carton. Check for signs that the

contents were damaged during shipment.

Keep the packaging. Take action within 24

hours if there is damage to the contents:

• Contact the delivery company and report

that the contents were damaged.

• Contact Fork Farms or your distributor for

a replacement.

Missing parts or need a replacement?

If you purchased your Flex Farm

directly through Fork Farms, contact

877.886.7736.

If your Flex Farm was purchased

through one of our distributors, please

contact them directly.

8

Section 2Flex Farm Assembly

2. Inspect the contents to make sure everything is there:

Description Qty

ACaster Unit

• Left Caster Frame

• Right Caster Frame

• Assembly Kit

1

1

1

Left Right Assembly Kit

BTanks

• Left Tank

• Right Tank

1

1

Left Right

CDrainage Valve 1

DLids

• Left Lid

• Right Lid

1

1

Left Right

ETank Knobs

• Knobs

• Screws

2

2

Knob Screw

FPump 1

GPump Filter Bag 1

ScrewNut Lock

Washer

9

Flex Farm AssemblySection 2

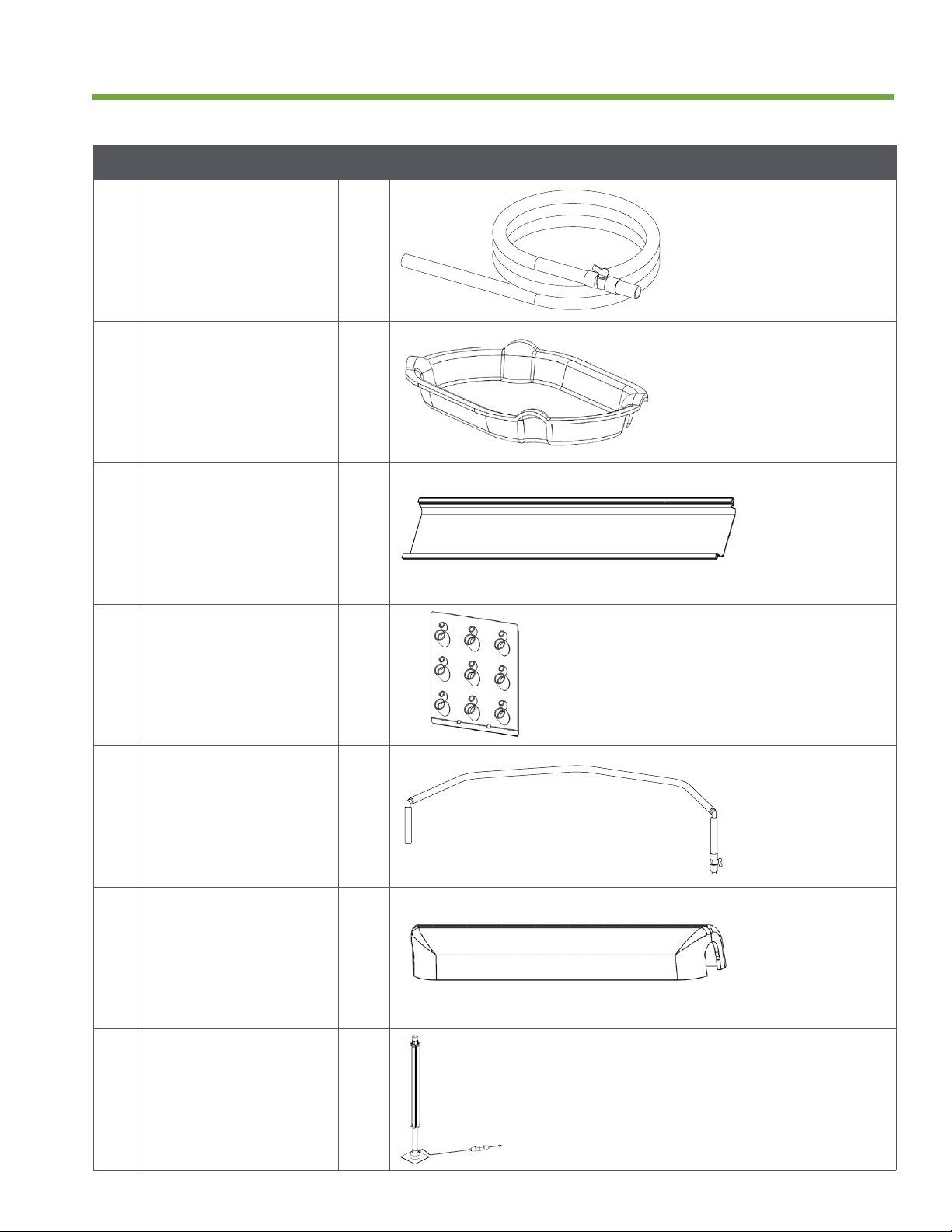

Description Qty

HVertical Irrigation

Line

1

ILid Plugs 2

JRoot Chambers 8

KPanels 32

LDrip Lines

• Left side has

Y-tting attached

2

MTop Caps 8

NLight Tower 1

10

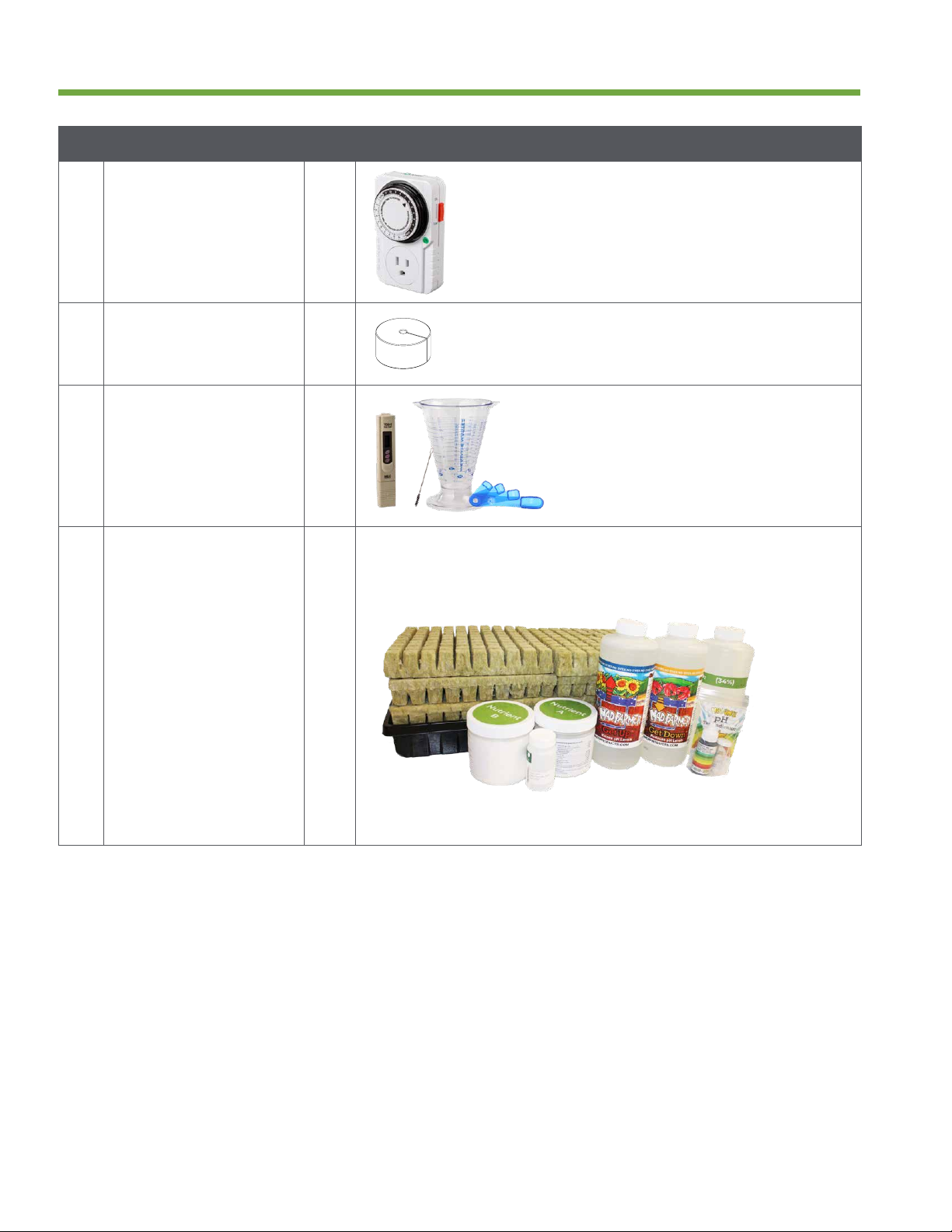

Section 2Flex Farm Assembly

Description Qty

OLight Timer 1

PPanel Plugs 150

QGrower Toolkit

• TDS Meter

• Measuring Cup

• Measuring Spoons

• Bristle Brush

1

1

1

1

RSupply Kit

• Rockwool Flats

• Nursery Tray

• Nutrient A (1 lb)

• Nutrient B (1 lb)

• pH Test Kit

• pH Down (1 qt)

• pH Up (1 qt)

• Food Grade

Hydrogen

Peroxide (1 qt)

• Seeds (jar)

4

1

1

1

1

1

1

1

1

11

Flex Farm AssemblySection 2

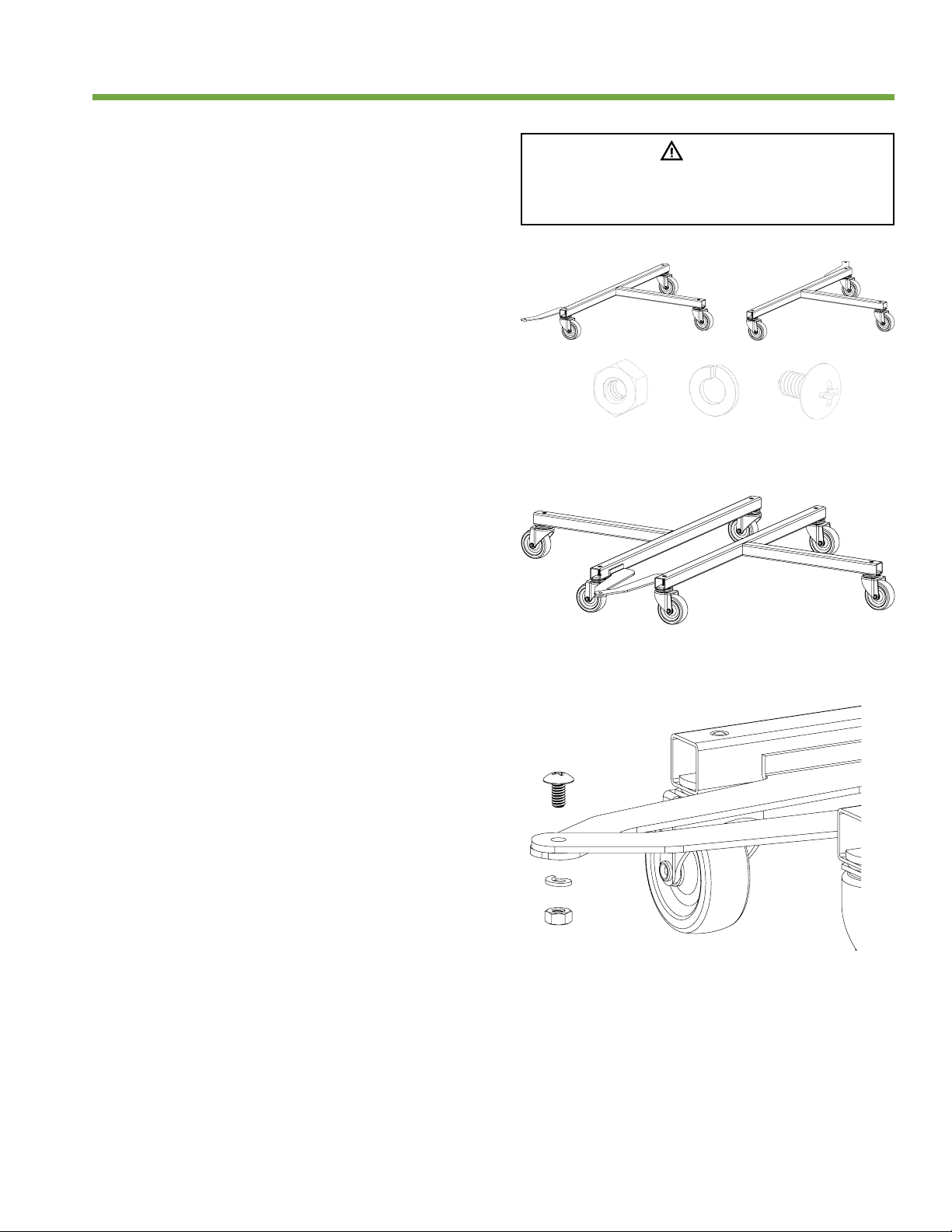

Assemble Caster Unit

1. Locate the caster unit (A) and an

adjustable or 3/8 inch wrench (optional).

NOTE: If your caster unit came

pre-assembled, skip to step 5.

2. Set the right and left sides of the caster

frame side-by-side on the oor, wheel

side down.

3. Line up the holes on each half and insert

the bolt through the overlapped holes.

4. Add the locking washer followed by the

threaded nut and hand tighten until

connection point is secure.

NOTE: An adjustable or 3/8 inch wrench can

be used to tighten if needed.

5. Set caster unit on the oor

wheel side down.

The pH solutions and hydrogen peroxide are

caustic materials. Keep out of reach of children.

Handle carefully to avoid personal injury.

Caution

A

12

B

F G

D

H I

E

C

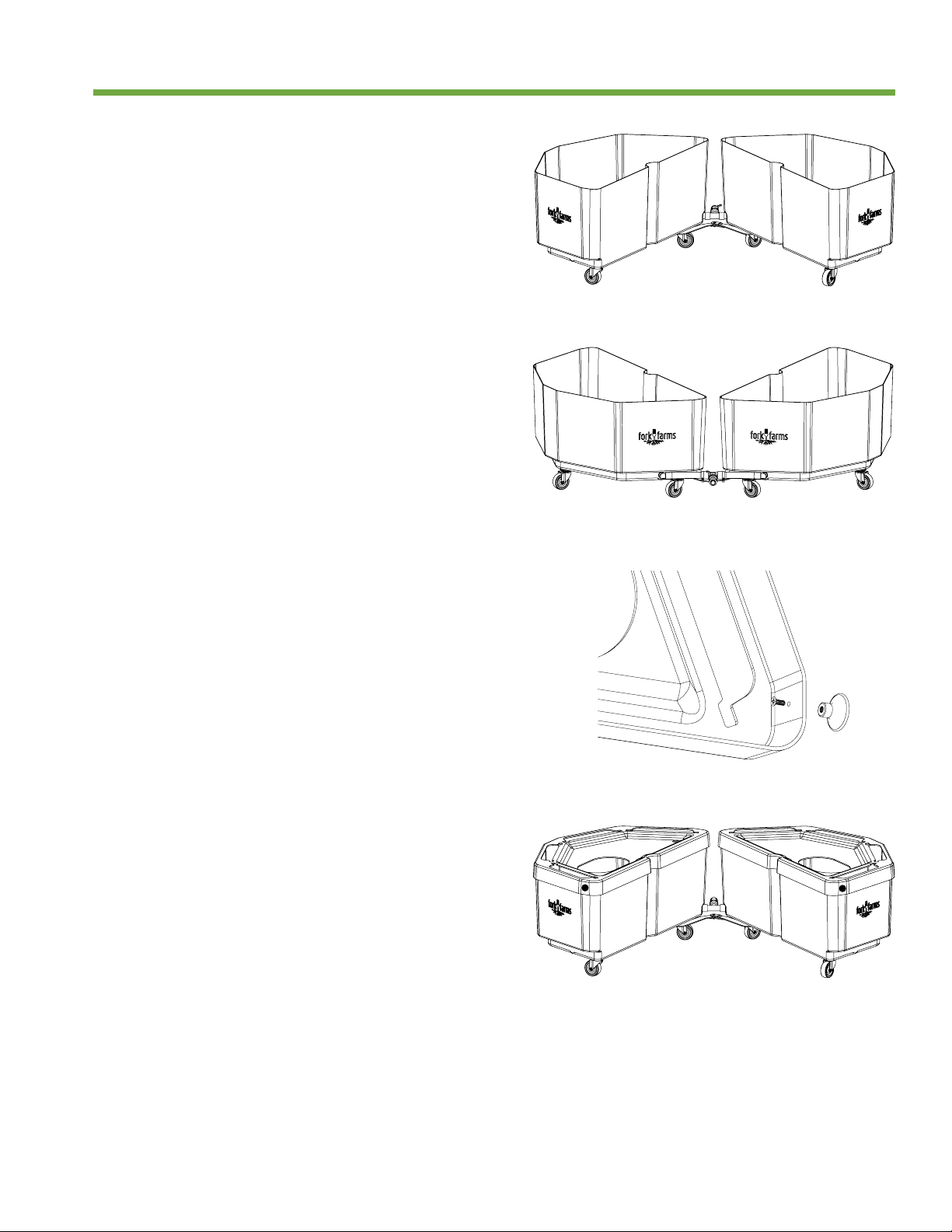

Assemble Tanks and Pump

1. Gather two tanks (B), drainage valve

(C), two lids (D), two tank knobs (E),

pump (F), pump lter bag (G), vertical

irrigation line (H), two lid plugs (I),

hair dryer (optional) and Phillips head

screwdriver (optional).

2. Connect the 3/4 inch vinyl tubing

attached to the back of both tanks to

the drainage valve.

NOTE: A hair dryer can be used to soften

the end of the tubing to ease assembly.

3. Hand tighten each end of the drainage

valve around the 3/4 inch vinyl tubing

and ensure the drainage valve is in the

closed position.

Section 2Flex Farm Assembly

Ensure tubing is securely attached. Improper

connection of tubing to either elbow or drainage

valve can cause leaking.

Notice

13

Section 2Flex Farm Assembly

4. Place the tanks on the caster unit,

aligning the caster frame to the grooves

in the bottom of the tanks.

NOTE: When properly assembled, the

drainage valve will be positioned directly

above where the caster unit halves are

attached to one another.

5. Attach one tank knob to each tank lid by

inserting a screw through each pilot hole

in the lid from the inside and twisting on

the knob by hand until tight.

NOTE: A Phillips head screwdriver can be

used to tighten tank knob if needed.

6. Put the tank lids on the tanks. Position

the large oval holes and tank knobs

closest to where the tanks separate.

NOTE: Place the lid with the small round

hole on the left tank.

14

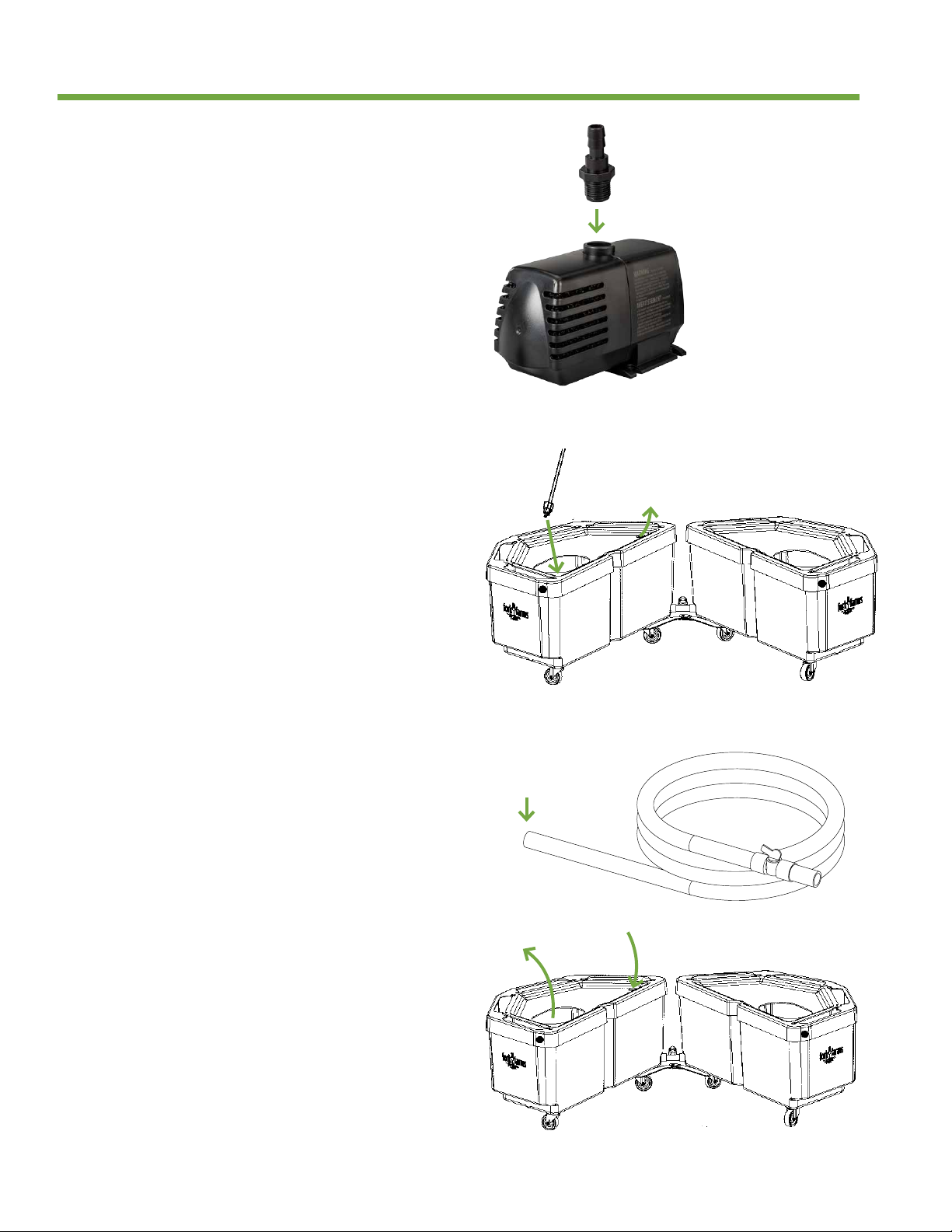

7. Take the pump out of the box and attach

the 1/2 inch tting (included with pump).

8. Set the pump on top of the left tank lid

and thread the power cord down through

the large oval opening and then back

out of the tank through the small round

opening in the lid.

9. Identify the end of the vertical irrigation

line farthest from the valve. In the

opposite direction as the power cord,

insert this end into the tank through the

same round opening.

10. Pull the vertical irrigation line out of the

tank through the large oval opening and

connect it to the 1/2 inch tting attached

to the pump.

Flex Farm AssemblySection 2

15

11. Place the pump into the pump lter bag,

allowing the power cord and vertical

irrigation line to exit the bag.

12. Tie the pump lter bag closed and place

the pump into the bottom of the tank

through the oval opening.

13. Gently pull the vertical irrigation line and

power cord exiting the tank to position the

pump near the back of the tank.

14. Insert a lid plug into the oval opening in

each tank.

Light will cause algae to bloom when it comes in

contact with Flex Farm water. Keep the lid plugs

inserted into the lids to prevent light from getting

into the tanks. Only remove the lid plugs to add

water or access the water supply.

Notice

Section 2Flex Farm Assembly

16

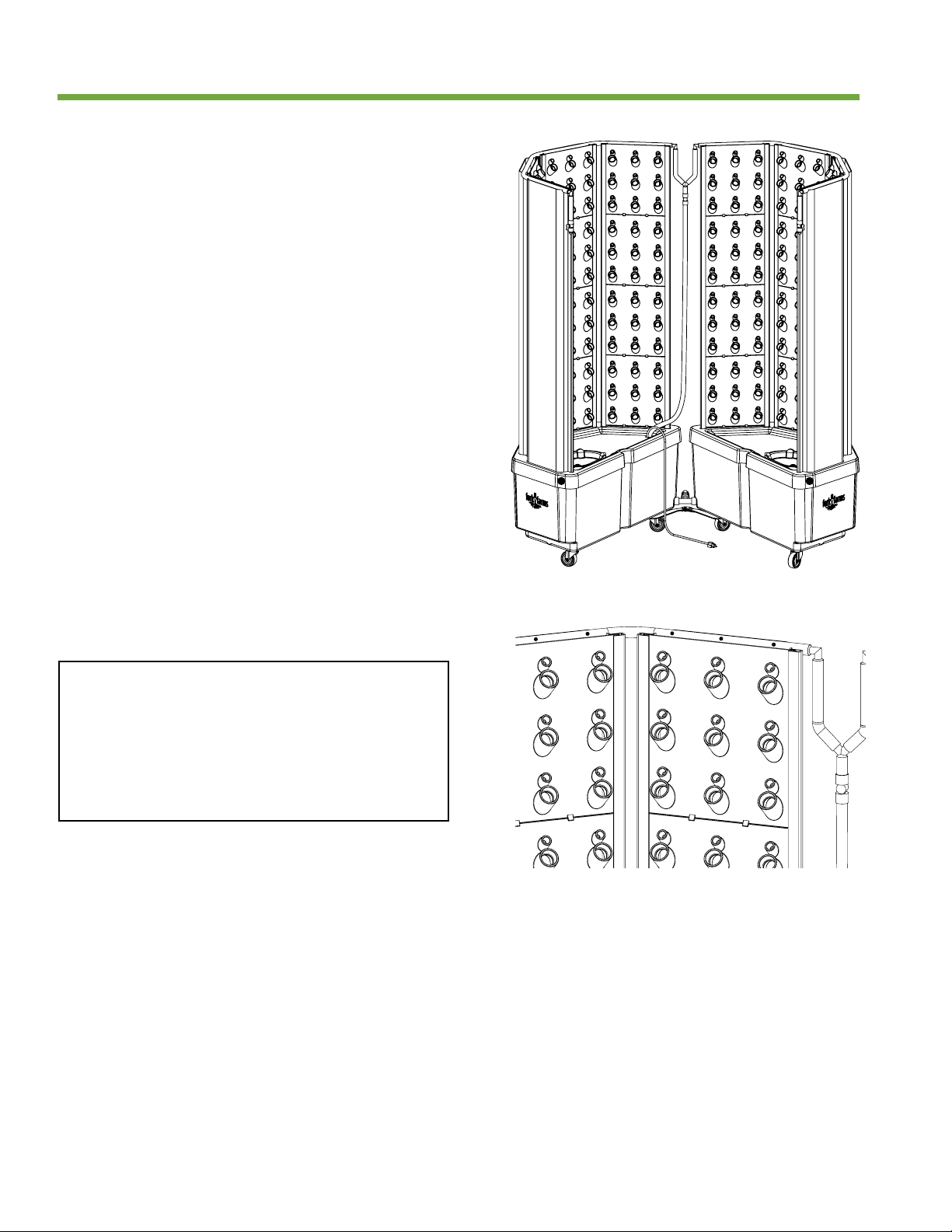

Assemble Root Chambers

and Panels

1. Gather eight root chambers (J), 32 panels

(K), two drip lines (L) and eight top caps (M).

2. Identify the side of the root chamber

without notches. Insert that side into the

tank through a slot in the tank lid. Repeat

until all eight root chambers are inserted

into the tank.

NOTE: A properly installed root chamber will

rest at and t around the raised area located

on the bottom of the tank with all notches

pointing upward.

J L

M

K

Flex Farm AssemblySection 2

17

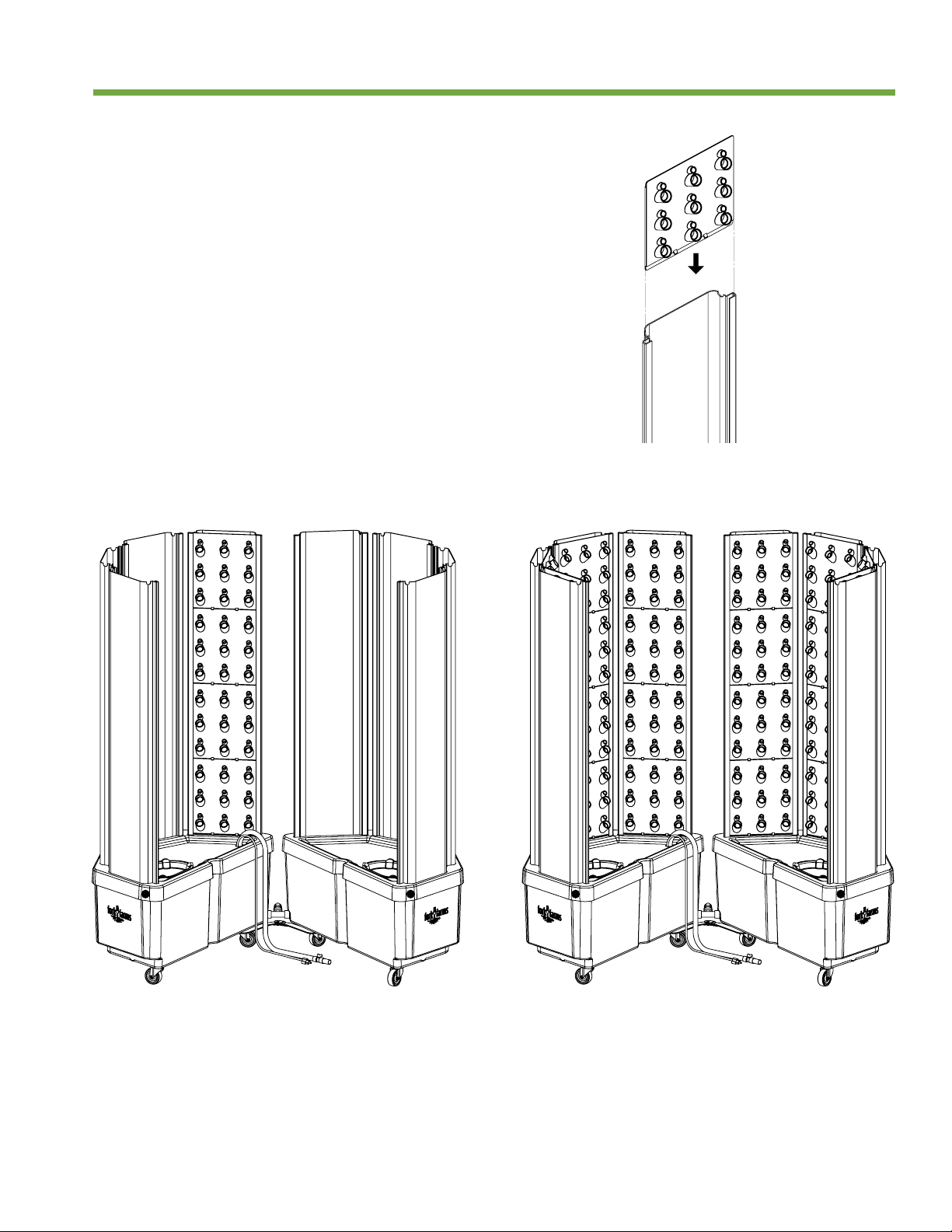

3. Insert four panels, one at a time, into the

top each root chamber by sliding them

through the rails located on each side.

NOTE: Insert panels tab side rst into root

chambers.

A

B C

Section 2Flex Farm Assembly

18

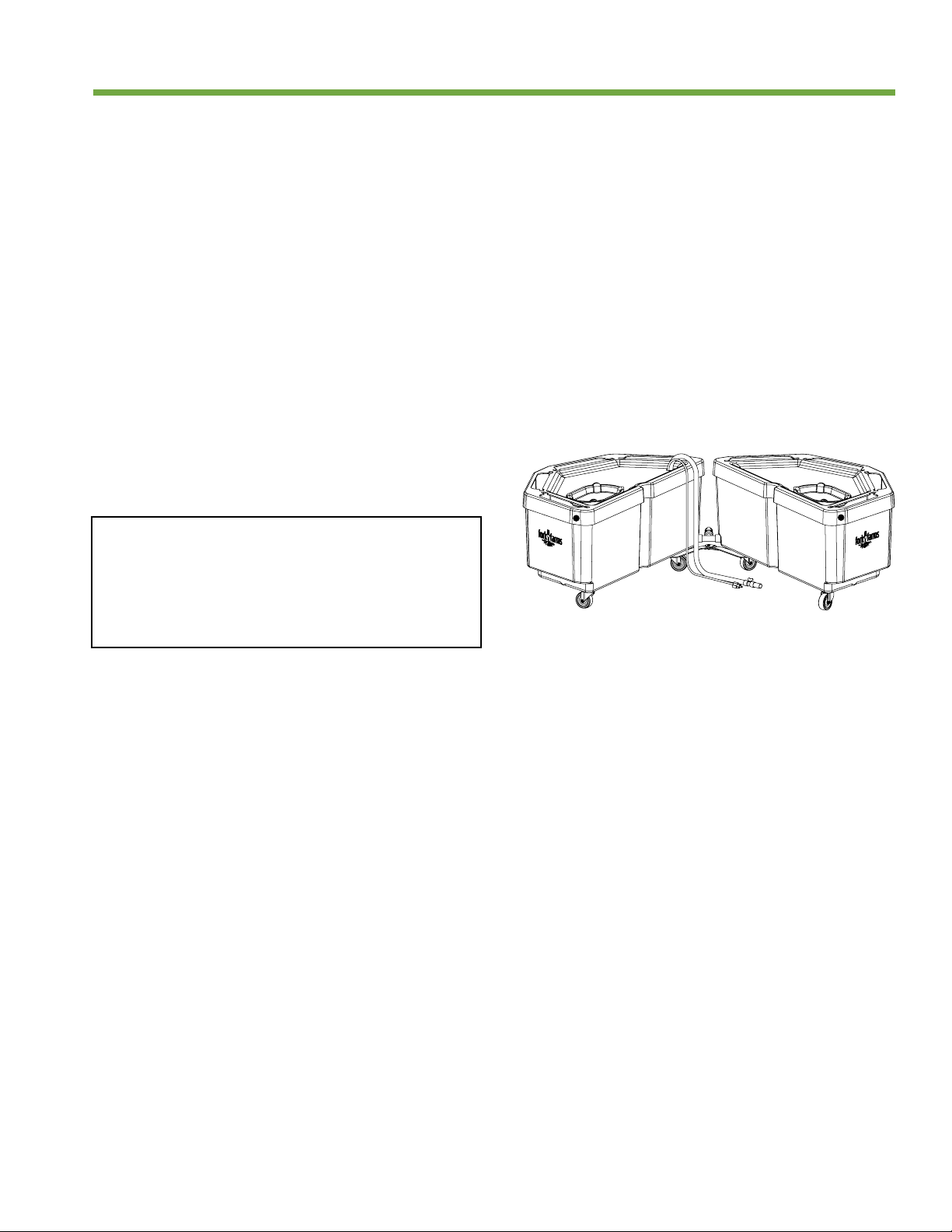

4. After all 32 panels have been installed, feed

each drip line through the notches at the

top of the root chambers, ensuring the

valves on each side are positioned closest

to where the Flex Farm opens.

NOTE: The left drip line will have a Y-tting

attached to the vinyl tubing on the opposite

side from where the valve is attached.

5. Connect the Y-tting attached to the left

drip line to the right drip line.

Take extra care to ensure the drip lines are installed

on the correct side with the holes positioned

directly behind each plant space in the top row of

each panel. Placing the drip lines on the incorrect

side may obstruct water ow, and failure to line

holes up with plant spaces may result in leaking

and/or plants not receiving enough water.

Notice

Flex Farm AssemblySection 2

Table of contents

Popular Farm Equipment manuals by other brands

CynkoMet

CynkoMet N-221/3-9 Instructions for Use and Operation

MacDon

MacDon M105 Operator's manual

Chore-Time

Chore-Time LIBERTY 53476 Installation and operator's manual

Miller

Miller AG-BAG Professional LX1214 Operator's manual

Producer's PRIDE

Producer's PRIDE Hill Country Coop Care Instructions

Unverferth

Unverferth ZONE-BUILDER 112 manual

Trejon

Trejon Terradisc 3000 Mounting instructions

Mayer

Mayer 1018 Series manual

Richiger

Richiger R990 Assembly instructions operator's manual parts list

Stara

Stara ASA H Instruction manual and parts catalog

Brouwer

Brouwer ROLLMAX 2400 Operator's manual

Redexim

Redexim Easy Spread 1500 Operator and parts manual