Carpenter Model 75 Compu-Strip®

Carpenter Model 75 Compu-Strip®•Phone: (315) 682-9176 • Fax: (315) 682-9160

Website: www.carpentermfg.com • Email: wire@carpentermfg.com

Revised June 10th, 2019 Page 4

Introduction

Thank you for choosing Carpenter Mfg. Co., Inc. for your wire processing equipment

needs. For over 60 years Carpenter has been a leader in wire processing technology

and service. As an independently-owned, third generation company our philosophy has

always been to provide the customer with both quality products and outstanding service.

We look forward to a long, healthy relationship with you and our company.

Every attempt has been made during the development of this operator’s manual to

include all relevant information pertaining to the operation and maintenance of the

Model 75 Compu-Strip® in an easy-to-read and easy-to-apply format. However, the

Model 75 is a complex piece of equipment and certain inaccuracies or typographical

errors may inadvertently be contained within these pages. Carpenter Mfg. Co., Inc.

shall not be held liable for these errors. We welcome customer input concerning this

operator’s manual. If you should find an error or have a suggestion on how this manual

could be enhanced, please feel free to contact us. Our phone number is (315) 682-

9176; we may also be reached by fax at (315) 682-9160. Visit our website

The Model 75 is a fully programmable wire and coaxial cable stripper that is designed to

strip a wide range of wire and cables, as referenced on the following pages. A great

amount of work has gone into the development of the Model 75, in order to offer a

product that is universally applicable to stripping the many varied types of cables within

its range of specifications. There may, however, be cables that fall within the Model 75

operating range that do not process satisfactorily on the Model 75. This may be due to

many factors, including but not limited to, cable construction, poor cable/material quality,

and/or required strip specifications. To determine if the Model 75 will satisfactorily

perform the stripping requirements, Carpenter Mfg. Co., Inc. strongly recommends a

free wire evaluation, to be completed at our factory (http://carpentermfg.com/wire-

evaluation/). A demonstration from a Carpenter representative is also recommended to

ensure the ultimate success of your wire processing application.

This operating manual explains how to operate the Model 75 Compu-Strip®. To ensure

the best performance of your machine, read this manual carefully until you familiarize

yourself thoroughly with its operation and features. After you have read through the

manual, keep it available for reference.

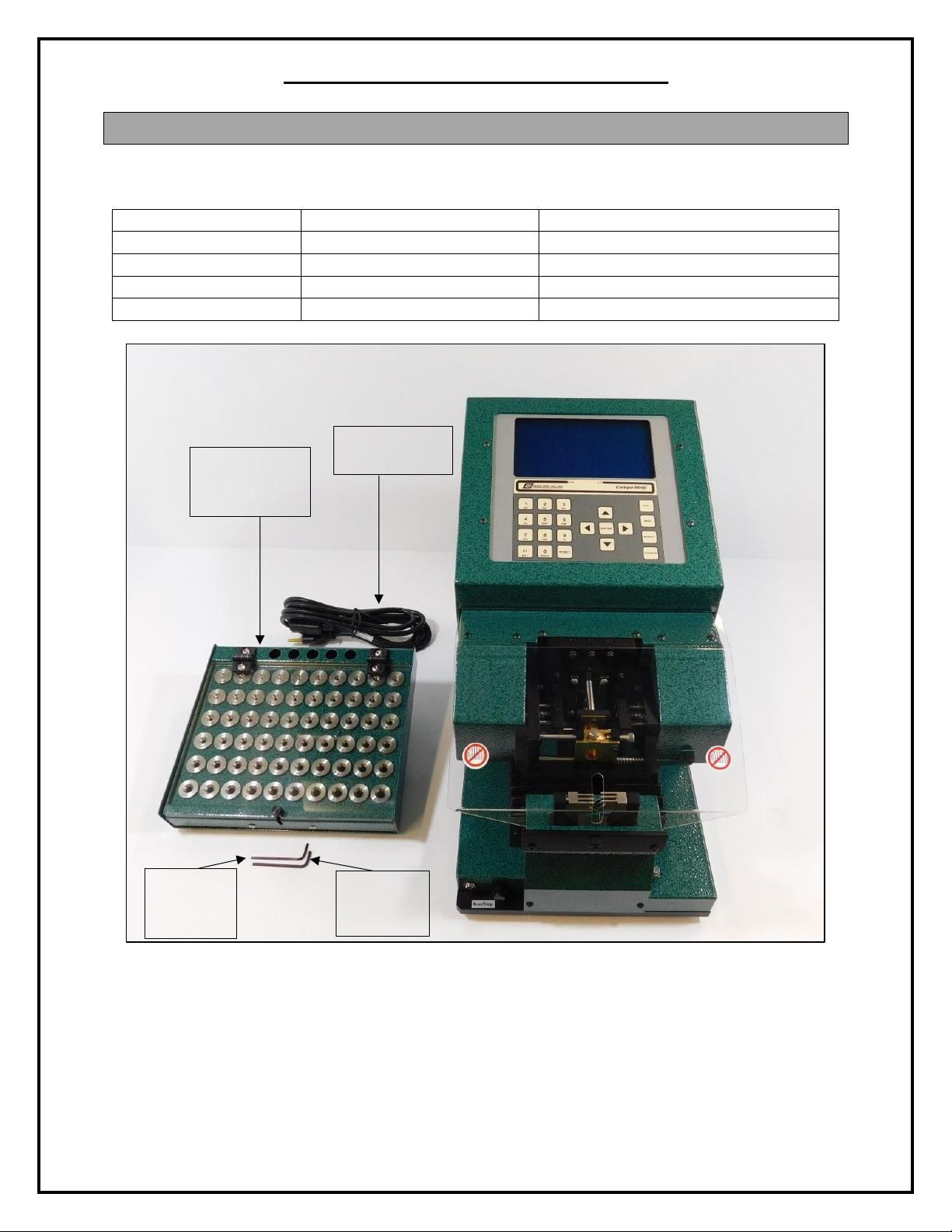

Carefully unpack the Carpenter Model 75 Compu-Strip®. We recommend that you

keep the original box and packaging as it will protect the machine for future

transportation, if necessary.