62-11850 4

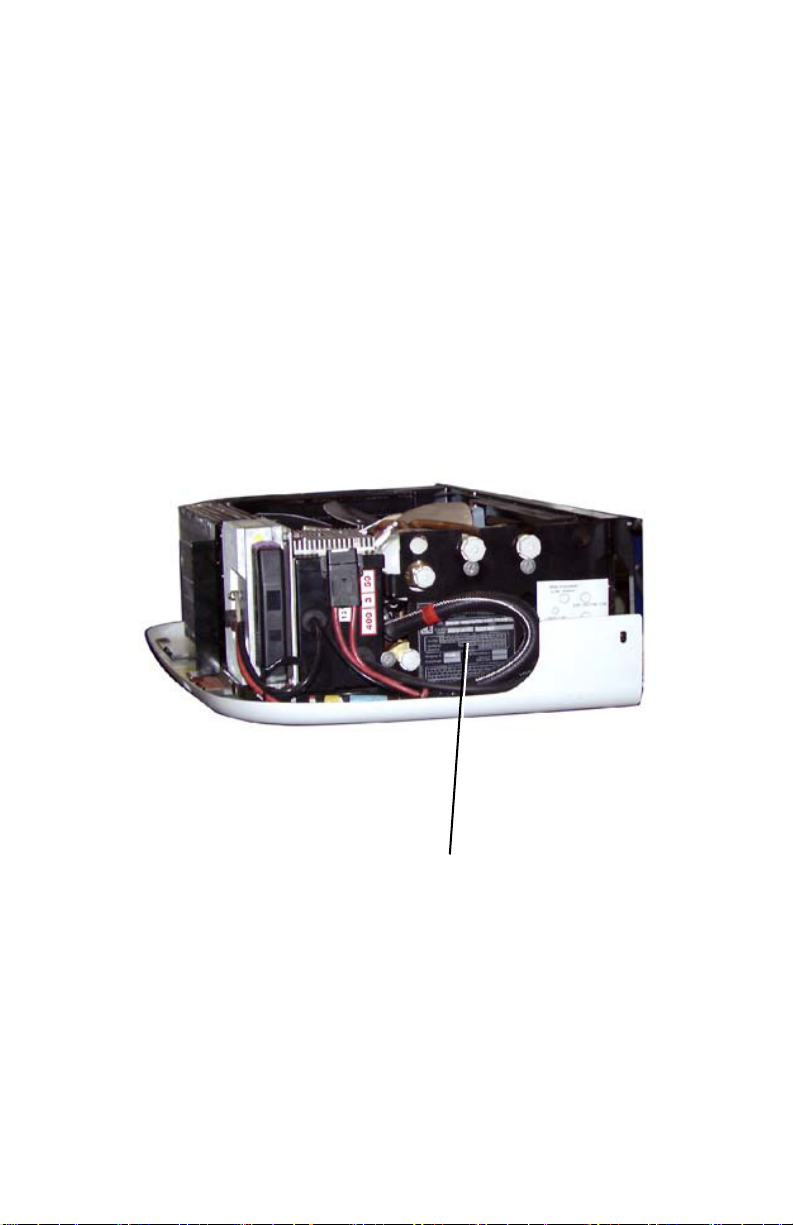

UNIT OPERATION

The Neos 100S is an all-electrical unit, powered by the vehicle battery

(alternator).

After starting up the refrigeration unit by pressing the ON key, the

microprocessor manages the unit regulation according to the box

temperature needed.

The unit automatically shuts down when the engine is switched off with

the ignition key.

The unit can be completely shut down manually by pressing the OFF key

on the Cab Command.

Standby Mode

The Neos 100S is powered by a standby module reducing the 230 VAC

into 12 Vdc. The power network connection is detected by the standby

module which automatically starts up the unit in standby mode.

If the ignition key is switched ON while the unit is connected to the power

network, or if the standby plug is connected while the unit is running, a

buzzer alarm will sound indicating the double power supply and the unit

stops.

Temperature Control

As soon as the set point temperature has been reached, temperature

control is obtained by shutdown and start-up of the electro-magnetic

clutch.

The condenser and evaporator fans cut out during regulation. When

transporting fragile loads such as fresh meat, vegetables and cheese, it is

possible to program the microprocessor to obtain continuous ventilation

by the evaporator during regulation.

Defrost

Defrost operation is fully automatic but can be manually controlled.

• Defrost cycles are fully controlled by the integrated microprocessor.

• During the defrost cycle, the evaporator fan shuts down. The con-

denser fan is controlled by the microprocessor.

• Defrost cycle termination is controlled by a defrost thermostat.

• During the defrost cycle, the cab command display indicates "dF".