2

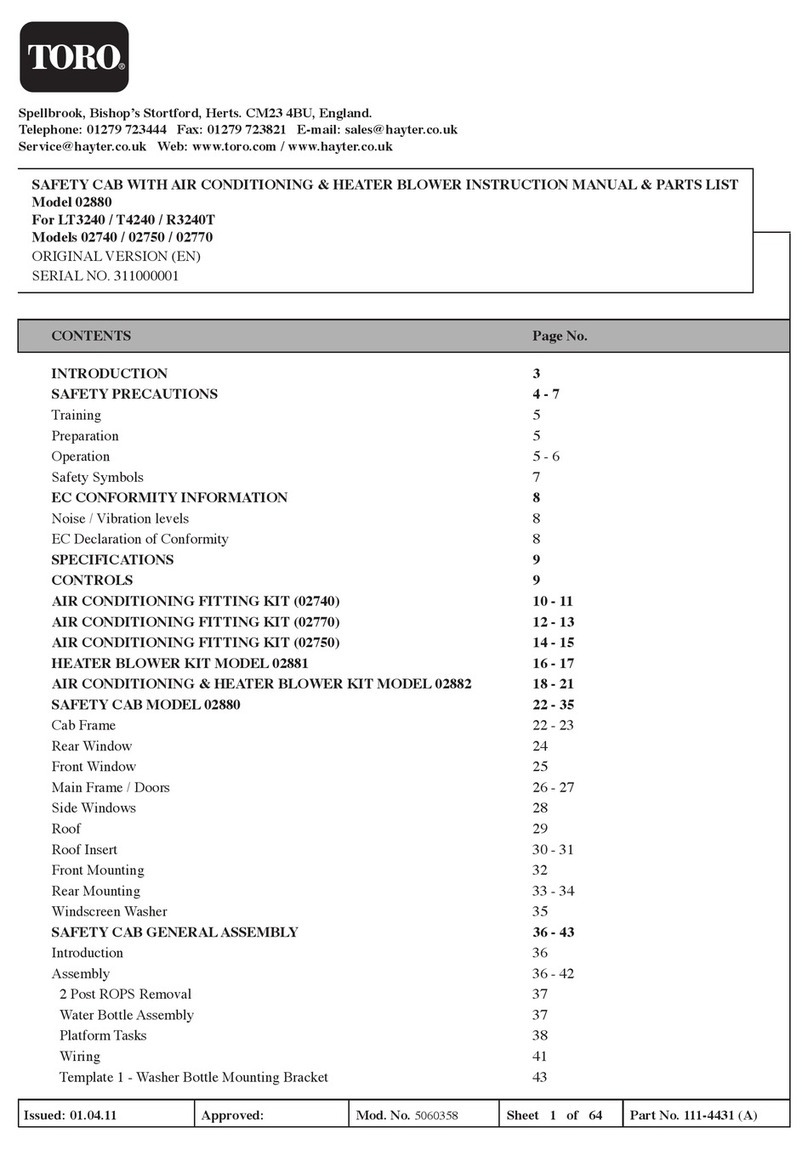

CONTENTS (cont) Page

CARRIER COMFORT NETWORK

INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43-45

RJ-11 Plug Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Monitor and/or Control from Non-CCN

Building Management System. . . . . . . . . . . . . . . . . 44

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-61

Initial Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Set Fan Status and Check Filter Switches . . . . . . . 46

• SUPPLY FAN STATUS SWITCH (FS)

• CHECK FILTER SWITCH (CFS)

Auxiliary Switch, Power Exhaust . . . . . . . . . . . . . . . . 46

Adjusting Set Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

• SET POINT FUNCTION

Program Time Sequences . . . . . . . . . . . . . . . . . . . . . . . 52

• SCHEDULE FUNCTION

Start Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Operating Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Head Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Control Loop Checkout. . . . . . . . . . . . . . . . . . . . . . . . . . 60

UNIT OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61-70

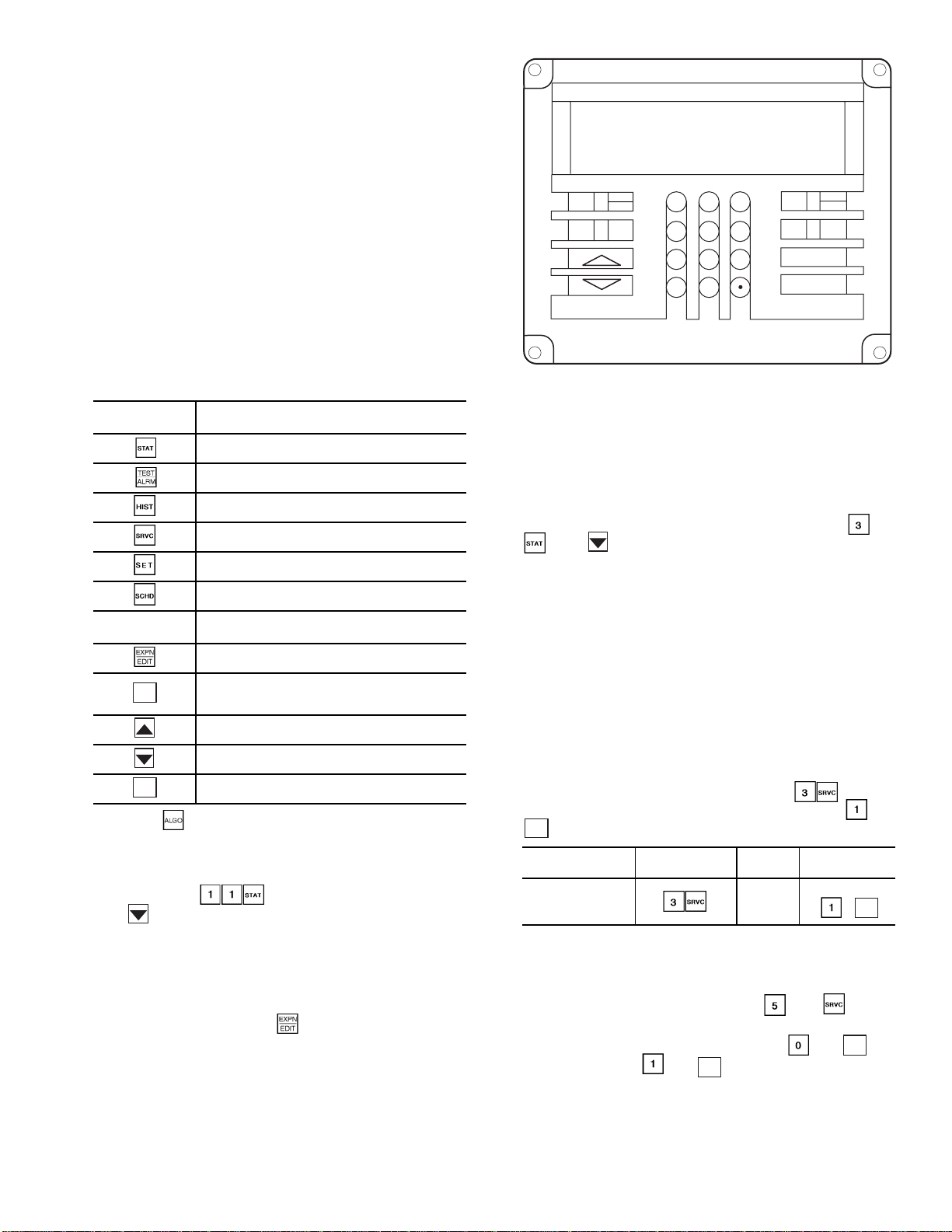

Status Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . 71-87

Checking Display Codes . . . . . . . . . . . . . . . . . . . . . . . . 71

Unit Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Complete Unit Stoppage . . . . . . . . . . . . . . . . . . . . . . . . 71

Single Circuit Stoppage . . . . . . . . . . . . . . . . . . . . . . . . . 72

Restart Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Alarm and Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

• DIAGNOSTIC ALARM CODES AND

POSSIBLE CAUSES

Thermistor Troubleshooting. . . . . . . . . . . . . . . . . . . . . 76

Transducer Troubleshooting. . . . . . . . . . . . . . . . . . . . . 80

Refrigerant Pressure Transducer

Replacement and Calibration. . . . . . . . . . . . . . . . . . 80

Control Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

• PROCESSOR MODULE (PSIO1), CONTROL

OPTION MODULE (PSIO2), AND HIGH-VOLTAGE

RELAY MODULES (DSIO1 AND DSIO2)

• RED LED

• GREEN LED

• PROCESSOR MODULE (PSIO1)

• HIGH-VOLTAGE RELAY MODULES

(DSIO1 AND 2)

• CONTROL OPTIONS MODULE (PSIO2)

• ACTUATORS

Economizer Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Variable Frequency Drive. . . . . . . . . . . . . . . . . . . . . . . . 84

Quick Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Forcing Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87-102

History Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Service Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Test Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Unit Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Appendix A — Input/Output

Tables 034-078 . . . . . . . . . . . . . . . . . . . . . . . . . . . 103,104

Appendix B — Input/Output

Tables 088,104 . . . . . . . . . . . . . . . . . . . . . . . . . . . 105,106

Appendix C — CCN Points List. . . . . . . . . . . . . 107,108

Appendix D — Bacnet Points List . . . . . . . . . . 109,110

Appendix E — Carrier Default Program

Parameter Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

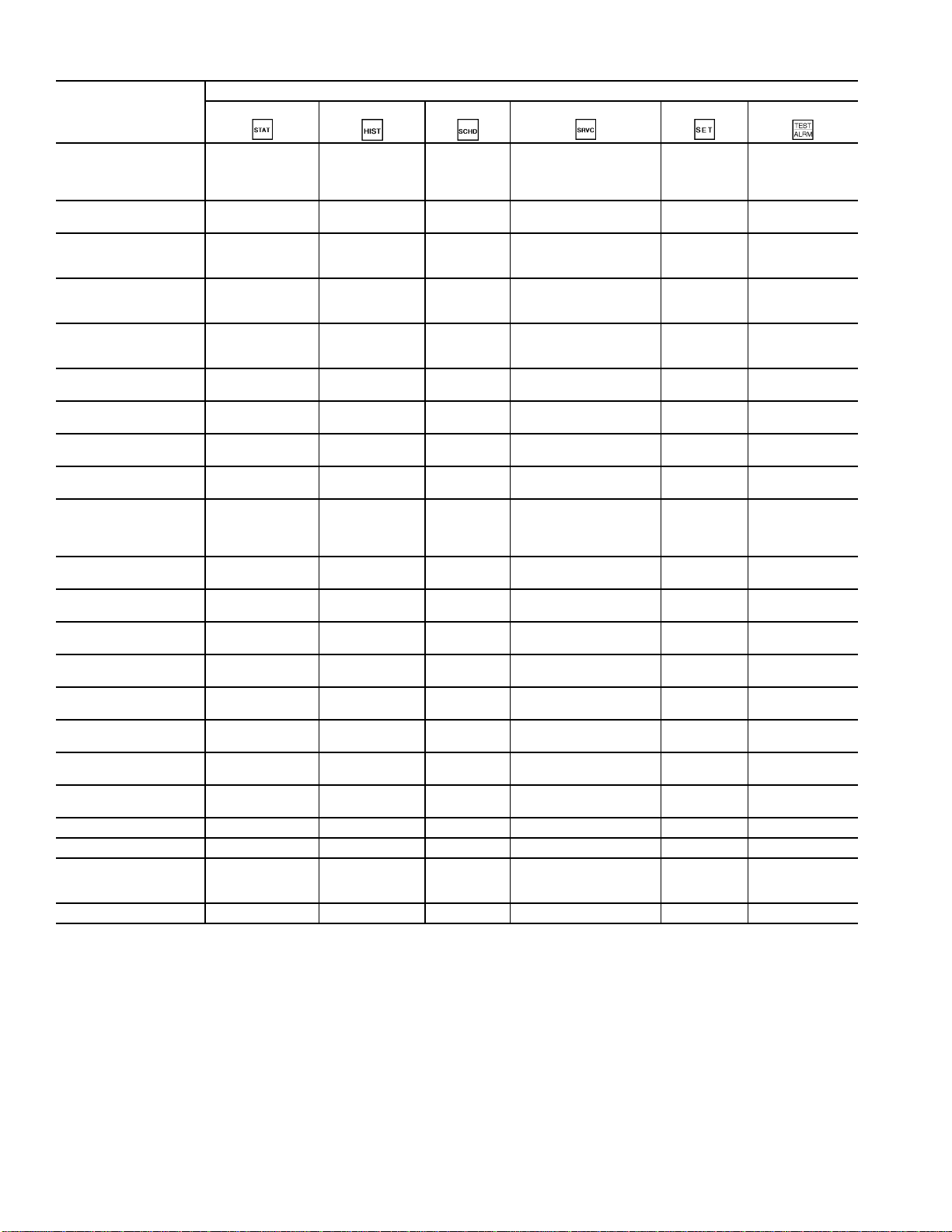

START-UP CHECKLIST . . . . . . . . . . . . . . . . .CL-1 to CL-4

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be

hazardous due to system pressures, electrical components; and

equipment location (roof, elevated structures, etc.). Only

trained, qualified installers and service mechanics should in-

stall, start up, and service this equipment

When working on this equipment, observe precautions in

the literature; on tags, stickers, and labels attached to the equip-

ment, and any other safety precautions that apply. Follow all

safety codes. Wear safety glasses and work gloves. Use care in

handling, rigging, and setting this equipment, and in handling

all electrical components.

GENERAL

This Controls and Troubleshooting book includes the fol-

lowing units and sizes:

• 48FP034-074

• 48JP034-064

• 48NP034-074

• 50FB034-104

• 50FP034-074

• 50FPX,FPY034-104 (extended plenum units)

• 50JB034-064

• 50JP034-074

• 50JPX,JPY034-064 (extended plenum units)

• 50NB034-074

• 50NP034-074

All units have Product Integrated Controls (PIC).

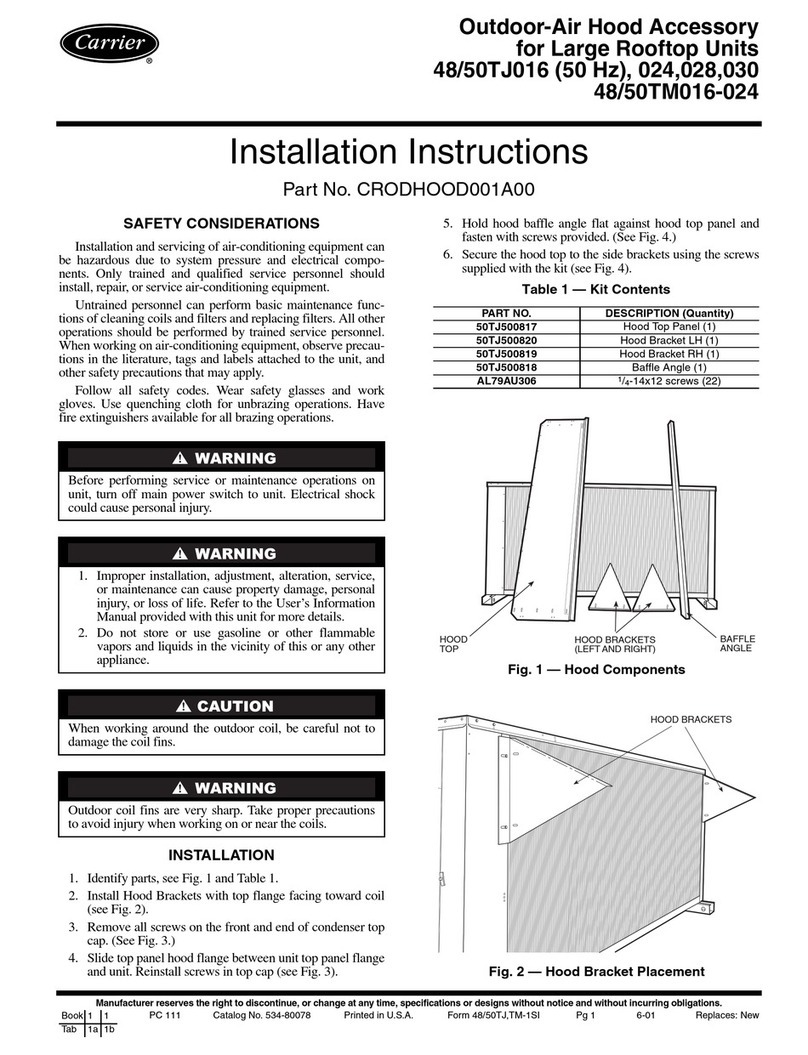

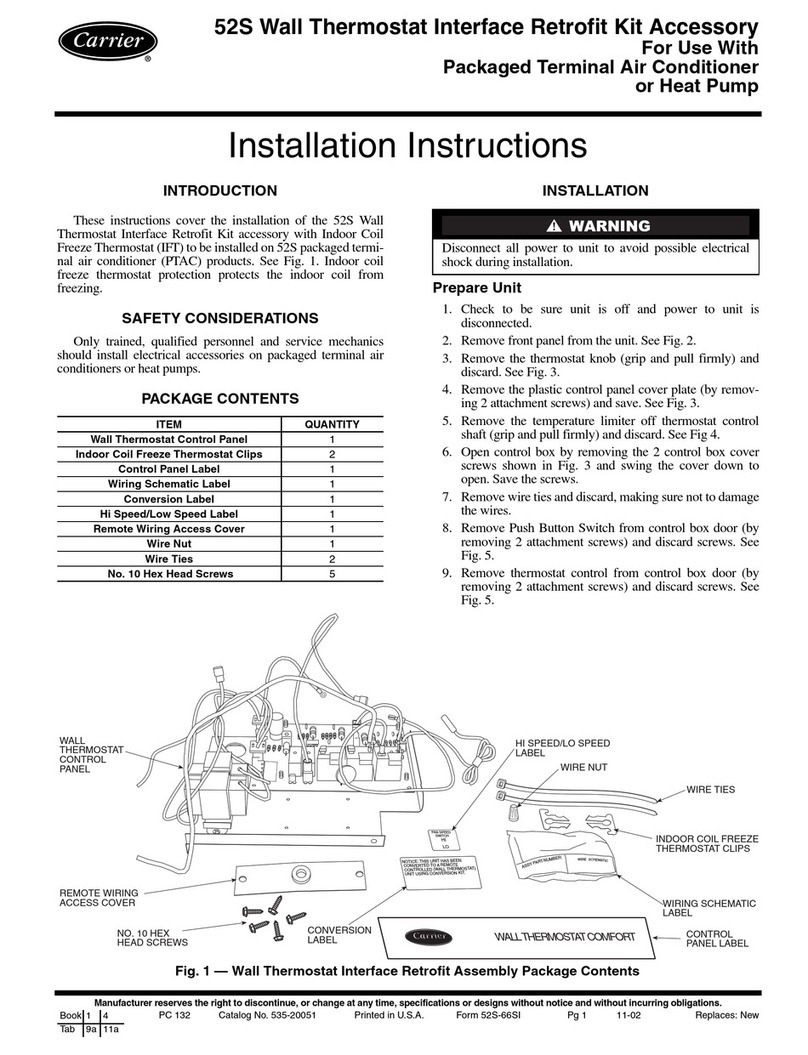

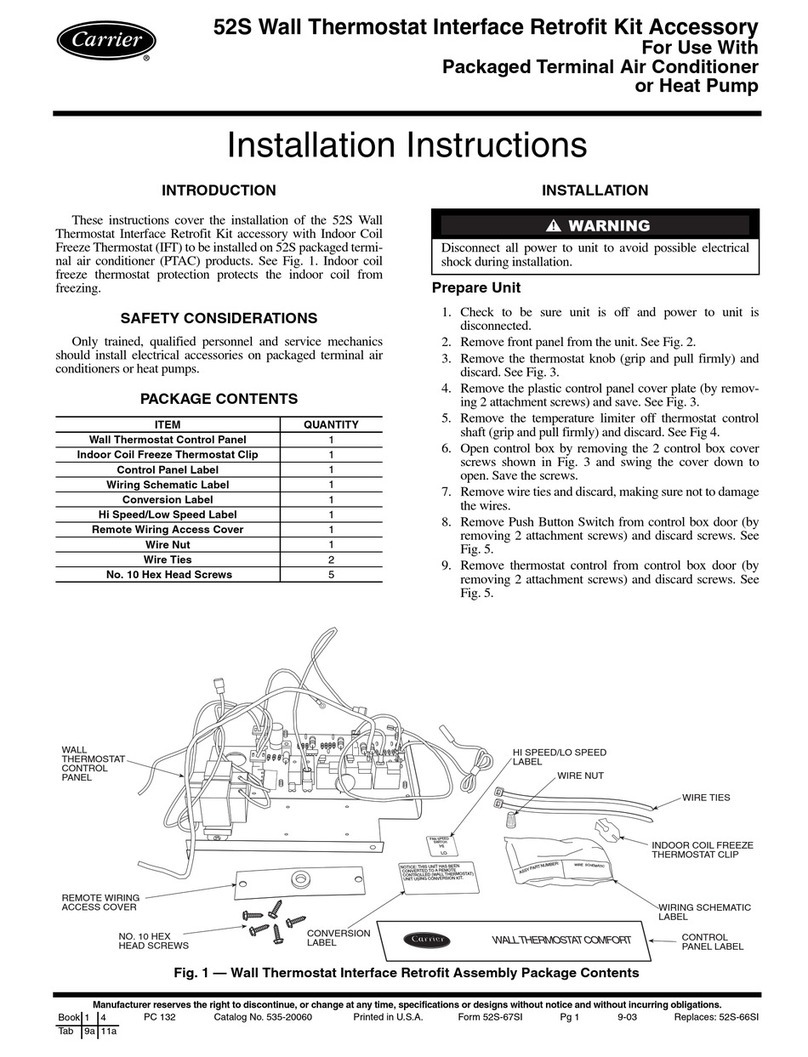

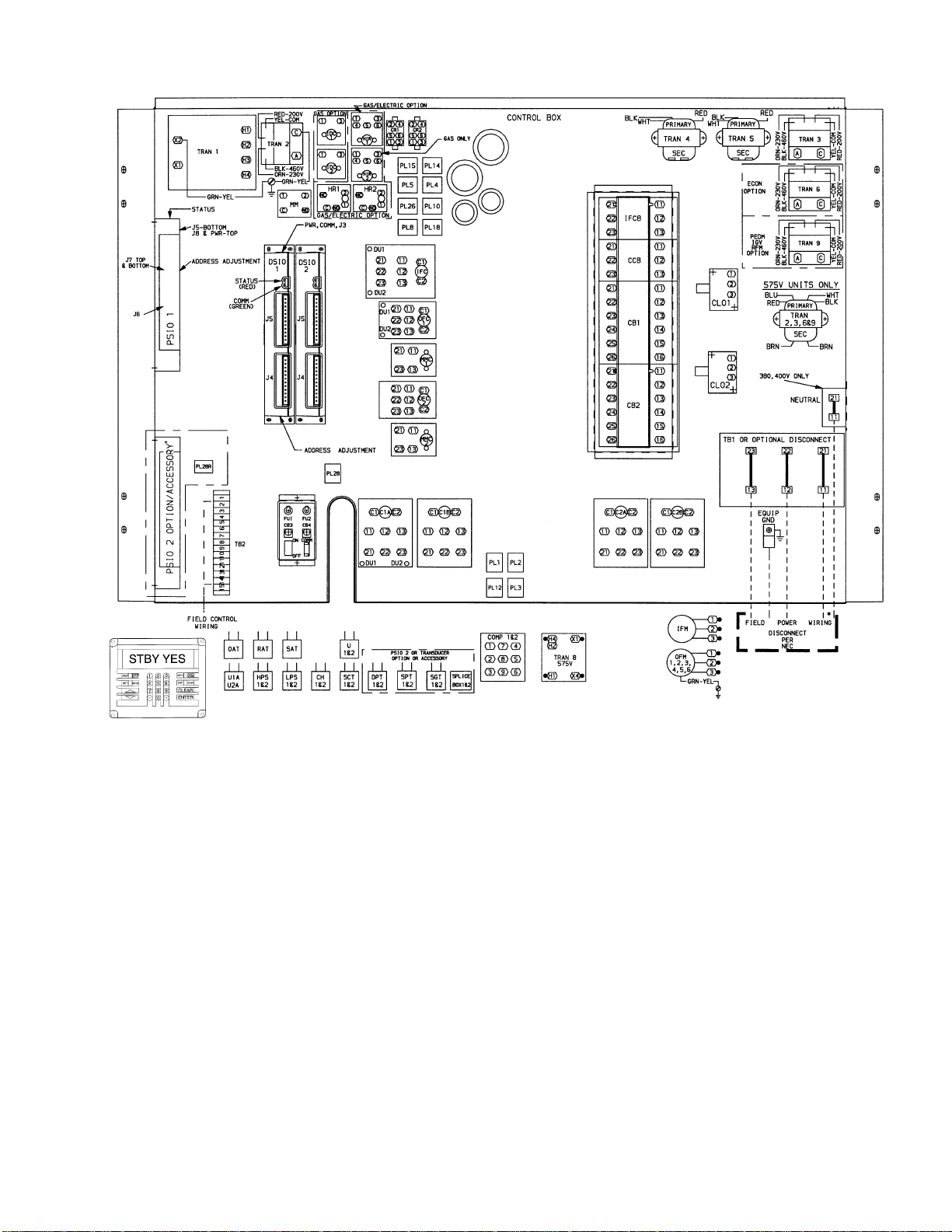

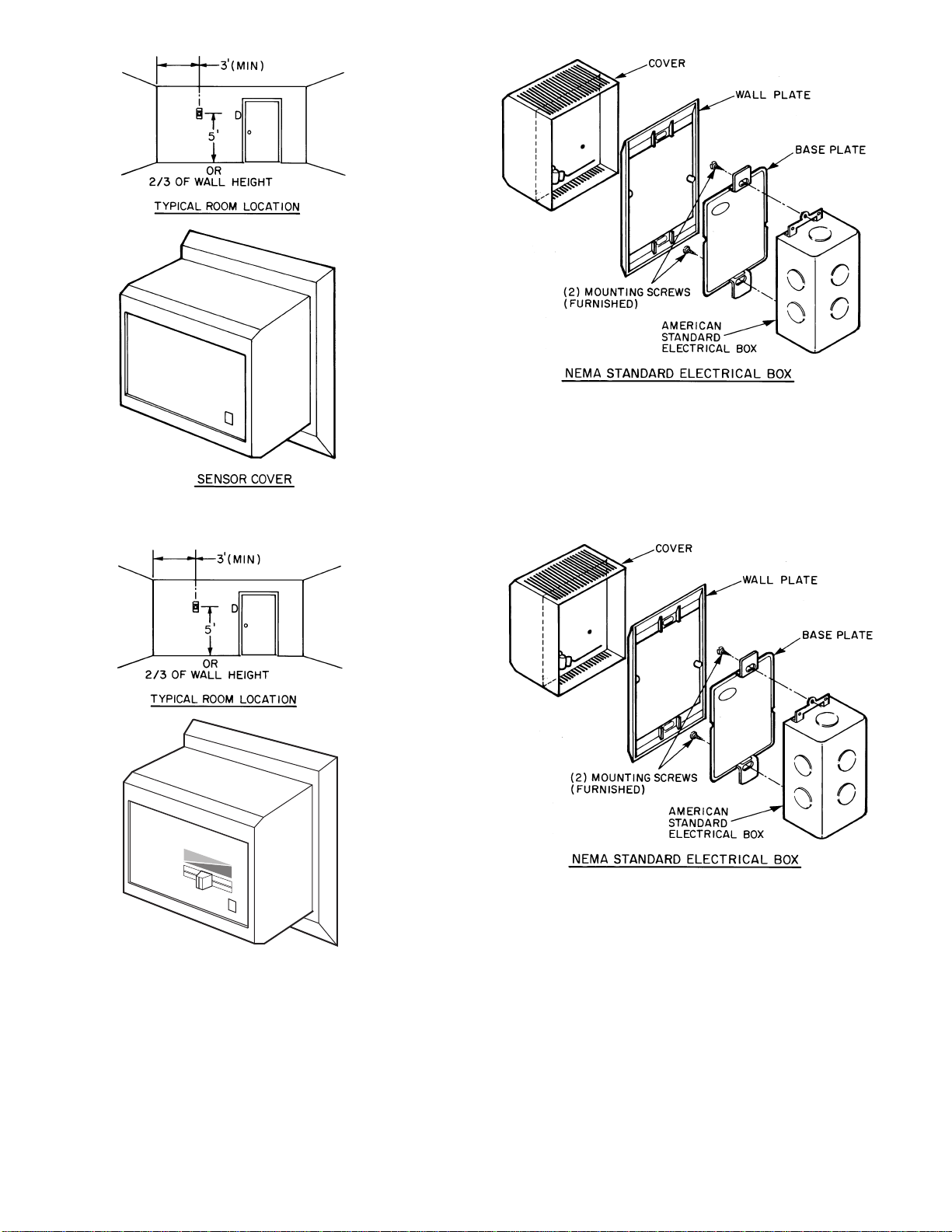

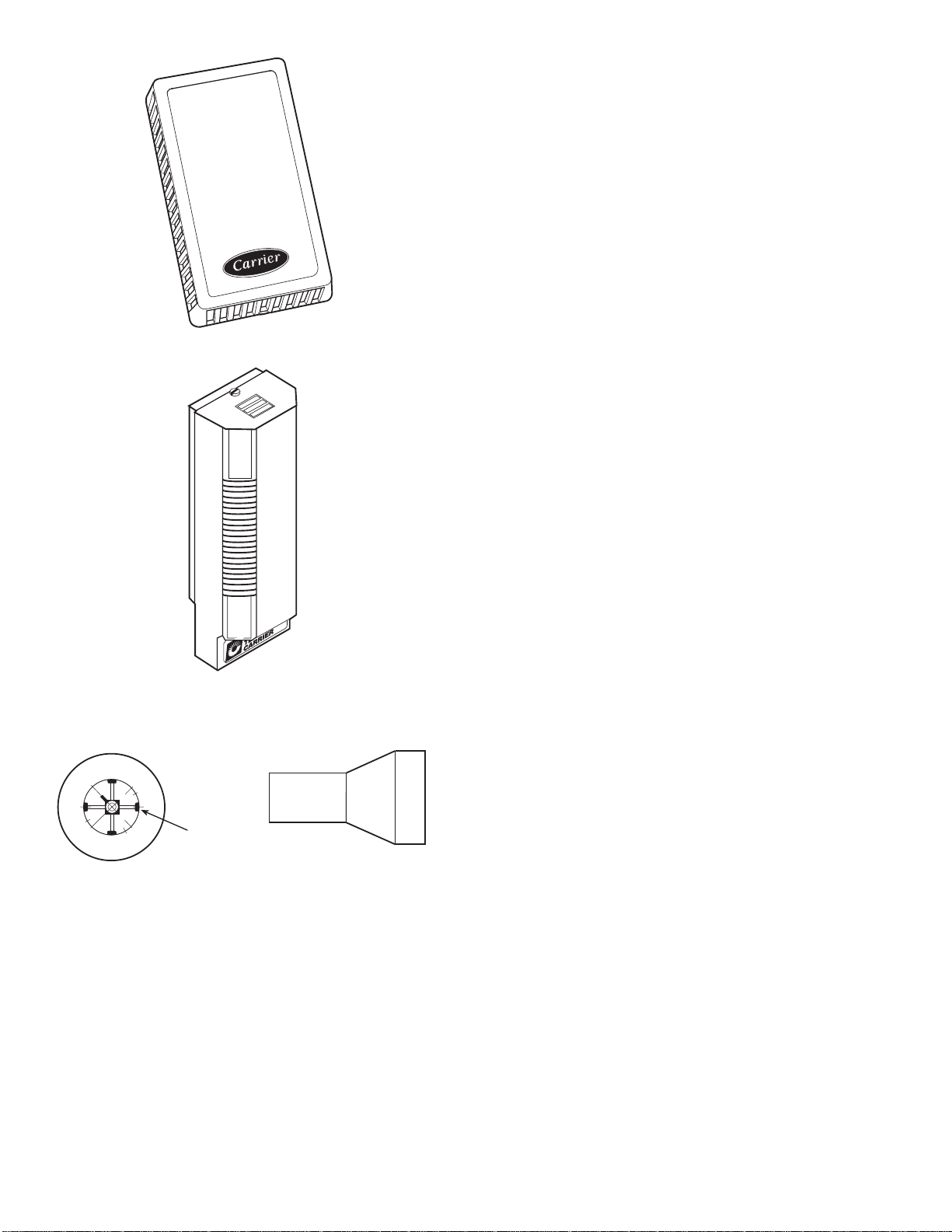

Carrier Comfort Network System Architecture

(Fig. 1)

These units provide ventilation, cooling, and heating (when

equipped) in Variable Air Volume (VAV) and Constant Volume

(CV) applications. The 48FP,JP,NP and 50FB,FP,JB,JP,NB,NP

units contain factory-installed Product Integrated Controls

(PIC) which provide full system management. Processor mod-

ules (PSIO) store hundreds of configuration settings and sever-

al building schedules. The PSIOs also perform self diagnostic

tests at unit start-up, monitor operation of the unit, and provide

alarms. Information on system operation and status are sent to

the central processors by various sensors that are located at the

unit and in the conditioned space. Access to the unit controls

for configuration, set point selection, schedule creation, and

service can be done through a unit-mounted keypad and dis-

play module (HSIO) which is available as an accessory. One

HSIO is required for each installation site. A separate HSIO

may be purchased for each unit, or a single HSIO may be

moved and installed on each unit as required. An HSIO may be

unit mounted or remotely located.

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation and ser-

vice. There may be more than one disconnect switch. Tag

all disconnect locations to alert others not to restore power

until work is completed.

This unit uses a microprocessor-based electronic control

system. Do not use jumpers or other tools to short out com-

ponents, or to bypass or otherwise depart from recom-

mended procedures. Any short-to-ground of the control

board or accompanying wiring may destroy the electronic

modules or electrical components.

IMPORTANT: This literature contains controls,

operation, and troubleshooting data for 48FP,JP,NP

and 50FB,FP,JB,JP,NB,NP rooftop units. Use this

guide in conjunction with the separate Installation

Instructions literature packaged with the unit.