acutherm THERMA-FUSER EL User manual

FORM 54.2 REV 0703

THERMA-FUSER™

EL - DDC INTEROPERABLE LINEAR VAV DIFFUSER

INSTALLATION, BALANCING & MAINTENANCE

Table Of Contents

INSTALLATION INSTRUCTIONS...........................................................................................2

CONNECTING WIRING ..........................................................................................................2

NETWORK CREATION AND COMMISSIONING OF EL DIFFUSERS..................................2

CREATE A LONMAKER NETWORK.......................................................................................................................3

INTRODUCE THE EL TO LONMAKER NETWORK...................................................................................................3

CREATE LONMAKER FUNCTIONAL BLOCK ..........................................................................................................3

CONFIGURE THE EL...........................................................................................................................................4

POWER FAILURE................................................................................................................................................7

BINDING NETWORK VARIABLES..........................................................................................................................7

PUTTING THE EL IN OPERATING MODE...............................................................................................................7

AIR DENSITY COMPENSATION............................................................................................7

SYSTEM AIR BALANCING ....................................................................................................7

TROUBLE SHOOTING ...........................................................................................................8

MAINTENANCE....................................................................................................................11

CONTROLLING THE SYSTEM.............................................................................................11

MEASURING ENERGY CONSUMPTION.............................................................................15

TWO YEAR WARRANTY .....................................................................................................15

DAMAGED FREIGHT CLAIM PROCEDURE

When the diffusers are received, inspect for damage, which may have occurred during shipment. If damage is

evident, it should be noted on the carrier’s freight bill. A written request for inspection by the carrier’s agent should

be made at once.

STORAGE

Cartons should always be stacked on end. Do not stack cartons flat on the sides. Excessive weight may cause

damage to the diffusers.

Do not store for prolonged times at temperatures exceeding 130°F(56°C). Acceptable humidity level 5-95% relative

humidity noncondensing.

IDENTIFICATION

Models are factory shipped one per carton. The model designation is on the diffuser and on the carton.

INSTALLATION PRECAUTIONS

When installing diffusers make sure construction debris does not enter the diffuser or duct system.

Because the EL controls room temperature by sensing the room air induced up from the room, care should be

taken not to disturb room air induction and entrainment

2

POWER REQUIREMENTS

24

+3

/

-2

VAC 18VA min.

INSTALLATION INSTRUCTIONS

1. inspect the carton for

damage before opening.

Notify carrier if external

damage exists. Submit all

claims for shipping damage

to the carrier.

2. Move cartons to installation

area. Note unit

identification.

3. Remove cardboard box and

cardboard insert. Discard

packing material.

4. Connect and secure the

supply duct to the collar.

Flexible duct should NOT

be formed in less than one

diameter turn.

5. Connect twisted pair

network wiring to either

screw terminals or RJ 45

jacks. For daisy chaining

connect both input and

output leads to screw

terminals or use one RJ 45

jack for input and the other

for output.

6. Connect 24 VAC power to

the screw terminal labeled

24 VAC.

7. Commission all EL

diffusers. See ‘Network

Creation and

Commissioning of EL

Diffusers’.

8. Balance the system. See

‘System Air Balancing’

CONNECTING WIRING

See detail above. The following steps are performed on each EL that is physically on site. If you are building the

network off site, these steps are completed after mechanical installation and during network commissioning.

1. Connect network cable to the EL ‘Network’ terminals. Two wires are required. A twisted pair is most commonly

used. The free topology FTT-10 transceiver can be used in bus, loop, star and daisy chain topologies. Two

RJ-45 terminals and one screw terminal on the EL allow for daisy chaining or temporarily connecting to a

computer.

2.

Connect 24 VAC to the ’24 VAC’ terminal of the EL.

NETWORK CREATION AND COMMISSIONING OF EL DIFFUSERS

Download the XIF file from Acutherm web site: www.acutherm.com.

This part of the document is prepared only for users having LonMaker For Windows as the network management

tool. Please refer to the specific user’s guide if you have other network management software. Refer to the

LonMaker User’s Guide and the LonMaker For Windows help file.

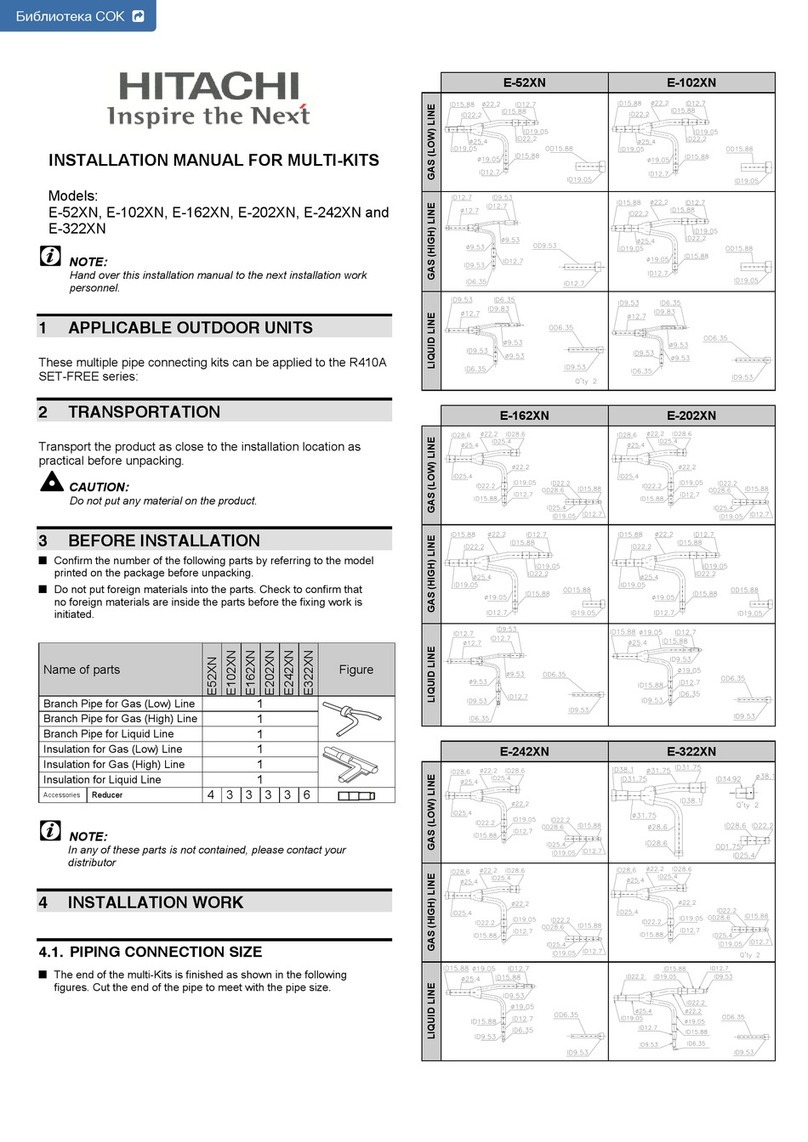

ONE AND TWO SLOT W2

NOMINAL

LENGTH ACTUAL

LENGTH INLET A B W1 2SLOT

1WAY 2SLOT

2WAY

36” 35 ¾” 5 7/8” 21 1/16” 14 11/16” 4” 3 ¾” 4 “

48” 47 ¾” 7 7/8” 28 1/16” 19 11/16” 4” 3 ¾” 4”

FOUR SLOT W2

NOMINAL

LENGTH ACTUAL

LENGTH INLET A B W1 4SLOT1 WAY

48” 47 ¾” 9 7/8” 28 1/16” 19 11/16” 6 5/16” 6”

3

Create a LonMaker Network

1. To create a new network:

From Windows desktop click on Start -> Programs -> LonMaker For Windows.

From the first window screen of LonMaker click on the ‘New Network’ button then enter the new network

name in the ‘Network Name’ field. Accept the default values for the ‘Network Database Path’ and ‘Network

Drawing Path’ then click on ‘Next’ and go to step 4.

2. To open an existing network:

From Windows desktop click on Start -> Programs -> LonMaker For Windows.

From the drop down list in the ‘Drawing Directory’ field, choose the network you want to open, then click on

‘Open Network’.

3. In the ‘Network Interface’ window, select ‘Network Attached’ if the PC is attached to the physical network and

you want to communicate with the devices. Accept the default ‘Network Interface’ or choose the appropriate

network interface if you have more than one network interface in your PC. Click ‘Next’.

4. Enter your user name and password if required. Check the ‘Write Access’ box if you are going to make

changes to the network.

5. If you are connected to the network, the ‘Management Mode’ window will appear. Check the ‘OnNet’ option if

you want changes to be propagated immediately to the device. If the ‘Offnet’ option is checked, changes won’t

be propagated to the devices on the network until LonMaker is ‘OnNet’. Click ‘Next’.

6.

The ‘Plug-in Registration’ window allows you to choose which plug-ins to register with this network. Click

‘Finish’.

Introduce The EL To LonMaker Network

1. Place a ‘Device’ shape on the drawing by dragging it from the LonMaker basic shapes stencil.

2. The ‘New Device Wizard’ window appears. Provide a ‘Device Name’ and select ‘Commission Device’ if

LonMaker is in the ‘Online’ mode. Press ‘Next’.

Note: If EL devices are added to the network in ‘Offline’ mode or ‘Commission Device’ option is not selected, a

‘Configuration Properties Warning’ box is displayed with the following contents: ‘There are no default

configuration properties available for this device. If this device was previously installed in another system, its

configuration properties values may need to be reset’. Click OK.

3. The ‘Specify Device Template’ window appears. If the EL being added is the first, check the ‘Load XIF’ option

and then select ‘Browse.’

Note: The XIF file provides LonMaker For Windows information about the EL.

4. Navigate to the directory where the EL.XIF file is located then double click on it. You will be returned to the

‘Select Device Template’ window with the ‘File’ and ‘Template Name’ fields defined based on your selection.

Press ‘Next’ to continue.

Note: If the EL being added has been placed on the drawing before, its template will already be available and

can be accessed by checking the ‘Existing Template’ option. Then the ‘Name’ can be selected from the drop

down list provided.

5. The ‘Specify Device Channel’ window appears. Select ‘TP/FT-10’ as the ‘Xcvr Type’ and if necessary select

the appropriate channel from the ‘Name’ drop down list. Press ‘Next’ to continue.

6. The ‘Specify Device Properties’ window appears. Accept the default settings and press ‘Next’ to continue.

7. The ‘Identify Device’ window appears. You can choose either the ‘Service Pin’ or ‘Manual’ method of

identifying the controller. Typically, the default service pin method is selected. Press ‘Next’ to continue.

8. The ‘Specify Device Application Image Name’ window appears. Typically no changes are required to this

screen so press ‘Next’ to continue.

9. The window titled ‘New Device Wizard’ appears. This is when you define the state of the device and the source

of the configuration property values. Select ‘Online’ for the state and ‘Default values’’ for the source of the

configuration properties values. Press ‘Next’ to continue.

10.

A screen appears prompting for a service pin. (See sketch, p. 10) Press the service pin on the EL to finish the

commissioning process. In the project drawing, the device shape should now be green indicating it is

addressed and online.

Create LonMaker Functional Block

1. A functional block represents a collection of network variables and configuration properties that perform a

related function on a device. To create functional blocks for the EL:

2. Place a Functional Block shape on the drawing by dragging it from the LonMaker Basic Shapes stencil.

The ‘New Functional Block Wizard’ window appears. This is where the device and functional block instances

are selected. In the ‘Device’ area, set the ‘Name’ of the EL associated with this functional block. In the

‘Functional Block’ area, set the ‘Name’ of the functional block to ‘Virtual Functional Block’.

4

Configure The EL

The EL unit is shipped with the default values shown below. When configuring, review the default values and

change only what is necessary

:

Configuration Variables

Function Description

Symbol On Screen

(SCPTs, SNVTs)

Default value Range Available

Occupancy

Temperature

Setpoint

The temperature setpoint of

the space to be maintained

by the EL for the

occupancy modes:

occupied, unoccupied,

standby.

SCPTsetPnts

1

23°C (73.4°F),

25°C (77°F),

27°C (80.6°F),

21°C (69.8°F),

19°C (66.2°F),

16°C (60.8°F)

50 – 95F (10 –35C)

1

This variable consists of six fields: Occupied cool, standby cool, unoccupied cool, occupied heat, standby heat,

unoccupied heat

Function Description

Symbol On Screen

(SCPTs, SNVTs)

Default value Range Available

Location

Label

This is designation for the

space in which the EL is

located, i.e. Conf Rm 12 SCPTlocation Blank Max length: 31 characters

Maximum

Flow Reserved for future use. SCPTmaxFlow 65535 l/s Do not change from

factory default setting.

Occupancy

Bypass Time

The amount of time in

seconds the EL operates in

occupied mode when the

occupancy input is set to

OC_BYPASS.

nciOccBypassTime 30 6553.4 secs.

Operation

Mode

Configures the EL to operate

in cooling only or heat and

cool mode. nciHeatCoolMode HVAC_AUTO

HVAC_AUTO,

HVAC_HEAT,

HVAC_COOL,

HVAC_MRNG_WRMUP,

HVAC_NIGHT_PURGE

Receive

Heartbeat

The maximum time that

elapses after the last update

to a bound network input

before the VAV object adopts

a default value for the

following: nviSpaceTemp,

nviSetpointOffset,

nviApplicMode,

nviEnergyHoldOff, nviCO2,

nviDuctTempIn

SCPTmaxRcvTime 0 0 sec – 6553.4 sec

Send

Heartbeat

The maximum period of time

that expires before the

following network variable

outputs will automatically be

updated: nvoSpaceTemp,

nvoUnitStatus, nvoBoxFlow,

nvoTerminalLoad,

nvoEffectSetPt,

nvoEnergyHoldff

SCPTmaxSendTime 0 0 sec – 6553.4 sec

Minimum

Send Time

The minimum period of time

between output network

variable transitions. SCPTminSendTime 0 0 sec – 6553.4 sec

5

Minimum

Flow Reserved for future use. SCPTminFlow 0 Do not change from

factory default setting.

Minimum

Flow

Standby Reserved for future use. SCPTminFlowStby 0 Do not change from

factory default setting.

Duct Area Reserved for future use. SCPTductArea 0 Do not change from

factory default setting.

CO2 Set

point Reserved for future use. nciCO2Threshold 5000 Do not change from

factory default setting.

Input Network Variables

Function Description

Symbol On Screen

(SCPTs, SNVTs)

Default value Range Available

Space

Temperature

Allows the EL to connect to a

space temperature sensor

other than the one installed in

the EL.

nviSpaceTemp 327.67°C

(621.806°F) 0 –327.67°C

(0 – 621.806°F)

Temperature

Setpoint

Allows the temperature

setpoint for the occupied and

standby modes to be changed

via the network. It is used to

reset the temperature rather

than change them.

nviSetPoint 327.67°C

(621.806°F) 10 – 35°C

(50 – 95°F)

Setpoint

Offset

Shifts the temperature control

point via the network. It is

typically bound to a

supervisory node providing

outside air temperature

compensation or to an

external wall diffuser having a

relevant setpoint knob.

Operates only on occupied

and standby setpoints.

nviSetPtOffset No offset =

32°F/0°C

-10°C to 10°C

(14°F to 50°F)

Occupancy

Commands the EL diffuser

into different occupancy

modes. It is typically set by a

supervisory node.

nviOccCmd OC_NUL

OC_OCCUPIED,

OC_UNOCCUPIED,

OC_BYPASS,

OC_STANDBY,

OC_NUL

Duct Inlet

Temperature

Allows the EL to be used with

another mfgr’s inlet

temperature sensor nviDuctInTemp 327.67°C

(621.806°F) 10 – 49°C

(50 – 120°F)

VAV Manual

Override Commands the controller into

a manual mode nviManOverride

HVO_OFF, 0.000, 0

2

See below

Emergency

Command

Commands the EL into

different emergency modes.

It is typically set up by a

supervisory node.

nviEmergCmd

EMERG_NORMAL

EMERG_NORMAL,

EMERG_PRESSURIZE,

EMERG_DEPRESSURIZE,

EMERG_PURGE,

EMERG_SHUTDOWN,

EMERG_NUL

Flow

Allows the EL to be used with

another manufacturers flow

sensor located on the

network.

nviBoxFlow 65535 l/s

(138862 cfm) 0 – 65535 l/s

(0 – 138862 cfm)

Table of contents

Popular Air Conditioner Accessories manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PAC-SNH11HS-E installation manual

Unitary products group

Unitary products group 2CE Series installation instructions

Qlima

Qlima EU-ODZ104 user manual

Tecnosystemi

Tecnosystemi smart clima SCD500163 user manual

Waeco

Waeco AirCon Service Center ASC 5300 G operating manual

American Standard

American Standard BAYSQRD001AA Installer's guide

Bimar

Bimar AP11 Instruction booklet

Mitsubishi

Mitsubishi PAC-SJ41TM-E installation manual

Tecnosystemi

Tecnosystemi Smart Clima SCD500084 user manual

Samsung

Samsung MIM-H04U User & installation manual

Waeco

Waeco AirConServiceCenter ASC 3500 G LE operating manual

Fujitsu

Fujitsu UTZ-KXGC installation manual