2

50ZPA

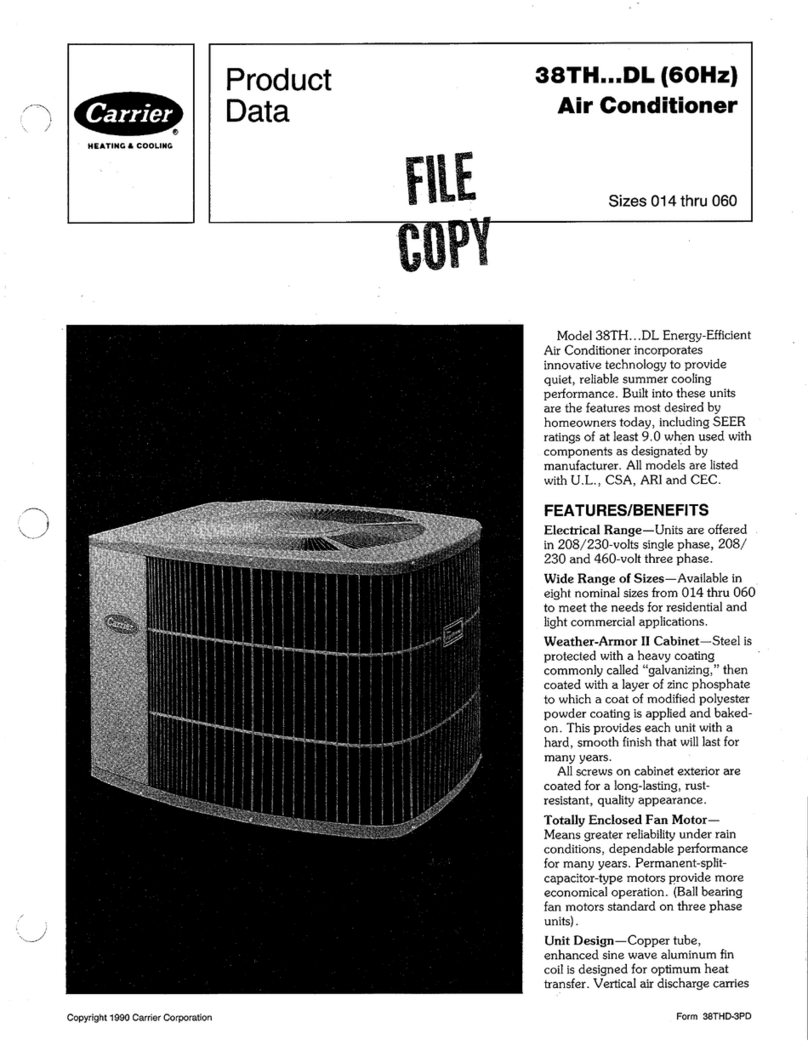

finish of the 50ZPA unit will keep it looking like

new for years. The paint treatment process

ensures quality protection against the elements.

A compact, low-profile design utilizes a

louvered coil enclosure for protection against

vandalism and hail damage.

INDOOR AIR QUALITY

is designed into the

50ZPA units. A sloped drain pan minimizes the

amount of standing water inside the unit, which

limits mold and mildew growth. The drain pan

is made of a rust-proof material and will not

deteriorate or release foreign matter into the

airstream.

LIGHTWEIGHT, COMPACT

CONSTRUCTION

is ideal for manufactured

housing and residential applications. The

50ZPA unit is one of the lightest, most compact

packaged units ever designed. It’s light weight

(293 lbs for the 50ZPA024 unit) makes the unit

easier to handle. The low height keeps ductwork

connections to a minimum and makes units less

visible.

The 50ZPA units utilize a structural beam

design to form the four sides of the cabinet.

Only 12 different pieces of sheet metal are used

in the unit construction to simplify the unit for

greater reliability.

EFFICIENT, DEPENDABLE

PERFORMANCE

with durable compressors

designed for efficiency. The 50ZPA units offer

13.0 SEER (Seasonal Energy Efficiency Ratio)

cooling performance efficiencies. This

performance level can reduce cooling expenses

by as much as 25% compared to older cooling

equipment. A high-eficiency, multi-speed

blower motor system ensures quality

performance with most duct systems. The

computer-designed blower wheel is balanced

for quiet operation.

DURABLE, DEPENDABLE,

COMPRESSORS

are designed for high

efficiency. Each compressor is hermetically

sealed against contamination to help promote

longer life and dependable operation. Vibration

isolation provides quiet operation. Compressors

have internal high-pressure and overcurrent

protection.

DIRECT-DRIVE MULTISPEED, PSC

(PERMANENT SPLIT CAPACITOR)

BLOWER MOTOR

is standard on all models.

Direct-drive, PSC condenser-fan motors are

designed to help reduce energy consumption

and provide for cooling operation down to 40°F.

REFRIGERANT SYSTEM

is designed to

provide dependability. Liquid refrigerant

strainers are used to promote clean, unrestricted

operation. Each unit leaves the factory with a

full refrigerant charge. Refrigerant service

connections make checking operating pressures

easier.

ACCESSORY ELECTRIC HEATERS

— A

variety of accessory electric heaters are

available for the 50ZPA units. These heaters are

comprised of a separate heater module mounted

on the blower inlet and remote mounted controls

located in the unit control box. Single point

electrical connections are available for

powering both the heater and the unit.

Corporate Thermostat

— These provide

cooling control for unit. Autochangeover and

manual changeover types are available.

The MotorMaster II Low Ambient Kit

— Kit

permits operation down to 0° F. Use when

mechanical cooling is required when outdoor-

air temperature is between 40°F and 0°F.

Crankcase Heater

— Warms crankcase oil to

reduce refrigerant migration and ensure proper

compressor lubrication. For use in applications

where crankcase is subjected to low outside

temperatures. Recommended on 208/230-1-60,

size 024-042 units only.

Solid-State Time Guard

®

Device

— Package

consists of a control to be field-wired into the

unit controls, and provides a 5-minute delay in

compressor operation between cooling cycles.

Prevents compressor short cycling when rapid

compressor cycles may be a problem.

Controls Upgrade Kit

— Contains high- and

low-pressure switches to protect the unit from

running at unsuitable pressures. Provides

additional safety features when needed.

Outdoor Thermostat

— Accessory provides

control when outdoor-air temperature falls

below set point. Helps to bring second stage of

2-stage electric heater on line.

Table of contents

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ARI Capacity Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Model Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Typical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Application Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Engineers’ Specification Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ARI* capacity ratings

UNIT 50ZPA

(SERIES)

NOMINAL

TONS

STANDARD

CFM

NET COOLING CAPACITIES

AT 95°F (Btuh)† SEER**

SOUND

RATINGS†† (dB)

024 2.0 800 24,000 13.0 77

030 2.5 1000 29,000 13.0 81

036 3.0 1200 36,000 13.0 81

042 3.5 1400 40,000 13.0 81

048 4.0 1600 45,000 13.0 81

060 5.0 1900 52,000 13.0 83

LEGEND

db

— Dry Bulb

dB

— decibels

SEER

— Seasonal Energy Efficiency Ratio

wb

— Wet Bulb

* Air Conditioning & Refrigeration Institute.

† Rated in accordance with U.S. Government DOE Department of

Energy) test procedures and/or ARI Standard 210/240-89.

** All units have factory-installed time-delay relay.

†† Rated in accordance with ARI Standard 270-84.

NOTES:

1. Ratings are net values, reflecting the effects of circulating fan heat.

2. Cooling capacity ratings are based on cooling standard:

80°F db/67°F wb indoor air entering temperature

95°F db air entering outdoor unit

M

A

N

U

F

A

C

T

U

R

E

R

C

E

R

T

I

F

I

E

D

T

O

A

R

I

A

S

C

O

M

P

L

Y

I

N

G

W

I

T

H

A

R

I

S

T

A

N

D

A

R

D

2

1

0

U

N

I

T

A

R

Y

A

I

R

C

O

N

D

I

T

I

O

N

I

N

G

E

Q

U

I

P

M

E

N

T

REGISTERED

ISO 9001:2000