8

For 30WGA units with remote condenser the installer must

be clearly note the total refrigerant charge used in the system

(in kg) on the label attached to the 30WGA.

RISK OF EXPLOSION: Never use air or a gas containing

oxygen during leak tests to purge lines or to pressurise a

machine. Pressurised air mixtures or gases containing oxygen

can be the cause of an explosion. Oxygen reacts violently

with oil and grease.

Only use dry nitrogen for leak tests, possibly with an

appropriate tracer gas.

If the recommendations above are not observed, this can

have serious or even fatal consequences and damage the

installation.

Never exceed the specied maximum operating pressures.

Verify the allowable maximum high- and low-side test

pressures by checking the instructions in this manual and

the pressures given on the unit name plate.

Do not unweld or amecut the refrigerant lines or any

refrigerant circuit component until all refrigerant (liquid

and vapour) as well as the oil have been removed from unit.

Traces of vapour should be displaced with dry nitrogen.

Refrigerant in contact with an open ame produces toxic

gases.

The necessary protection equipment must be available, and

appropriate re extinguishers for the system and the

refrigerant type used must be within easy reach.

Do not siphon refrigerant.

The accidental releases of the refrigerant, due to small leaks

or signicant discharges following the rupture of a pipe or

an unexpected release from a safety valve, can cause frostbites

and burns to personnel exposed. Do not ignore such injuries.

Installers, owners and especially service engineers for these

units must:

- Seek medical attention before treating such injuries.

- Have access to a rst-aid kit, especially for treating eye

injuries.

We recommend to apply standard EN 378-3 Annex 3.

Avoid spilling liquid refrigerant on skin or splashing it into

the eyes. Use safety goggles and safety gloves. Wash any

spills from the skin with soap and water. If liquid refrigerant

enters the eyes, immediately and abundantly ush the eyes

with water and consult a doctor.

Never apply an open ame or live steam to a refrigerant

container. Dangerous overpressure can result.If it is necessary

to heat refrigerant, use only warm water.

During refrigerant removal and storage operations follow

applicable regulations. These regulations, permitting

conditioning and recovery of halogenated hydrocarbons

under optimum quality conditions for the products and

optimum safety conditions for people, property and the

environment are described in standard NF E29-795.

Any refrigerant transfer and recovery operations must be

carried out using a transfer unit.3/8” SAE connectors on the

liquid, suction and discharge lines are available for all units

for connection to the transfer station. The units must never

be modied to add refrigerant and oil charging, removal and

purging devices.All these devices are provided with the units.

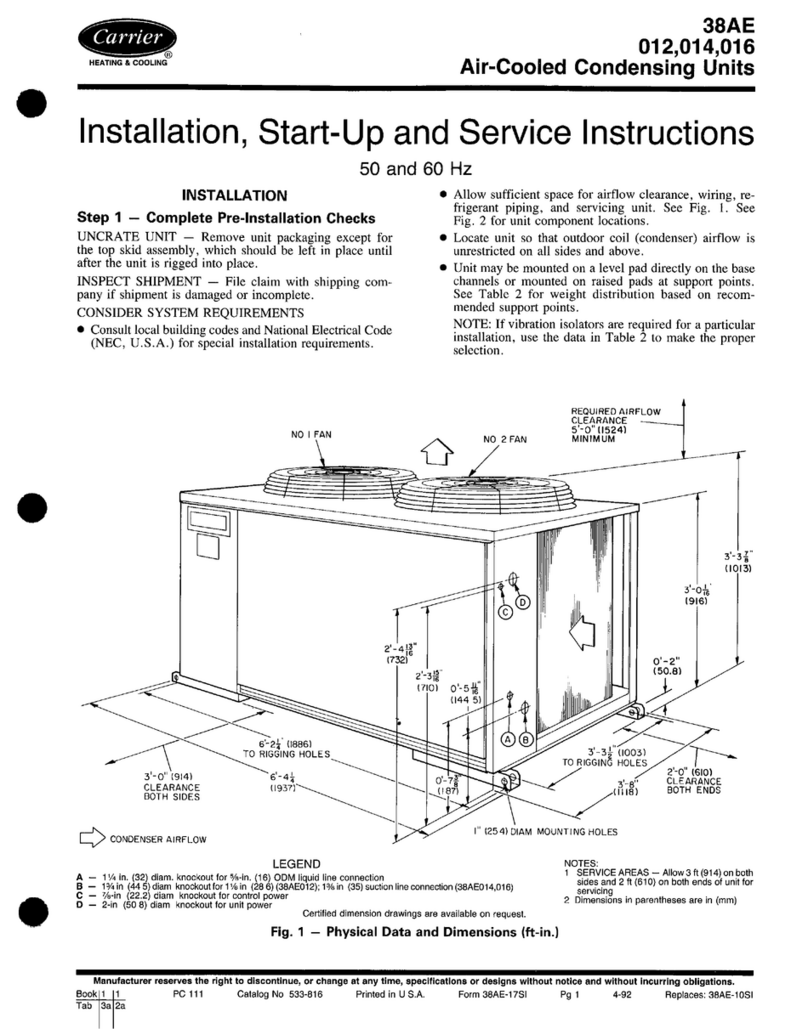

Please refer to the certied dimensional drawings for the

units.

Do not re-use disposable (non-returnable) cylinders or

attempt to rell them. It is dangerous and illegal. When

cylinders are empty, evacuate the remaining gas pressure,

and move the cylinders to a place designated for their

recovery. Do not incinerate.

Do not attempt to remove refrigerant circuit components

or ttings, while the machine is under pressure or while it

is running. Be sure pressure is at 0 kPa and that the unit

has been shut down and de-energised before removing

components or opening a circuit. If the refrigerant circuit

is open to carry out a repair, all circuit openings must be

plugged, if the repair takes longer than 30 minutes. This

prevents humidity from contaminating the circuit, especially

the oil. If the work is expected to take longer, charge the

circuit with nitrogen.

Do not attempt to repair or recondition any safety devices

when corrosion or build-up of foreign material (rust, dirt,

scale, etc.) is found within the valve body or mechanism. If

necessary, replace the device. Do not install safety valves in

series or backwards.

ATTENTION:No part of the unit must be used as a walk-way,

rack or support. The refrigerant lines can break under the

weight and release refrigerant, causing personal injury.

Do not climb on a machine. Use a platform, or staging to

work at higher levels.

Use mechanical lifting equipment (crane, hoist, winch, etc.)

to lift or move heavy components. For lighter components,

use lifting equipment when there is a risk of slipping or

losing your balance.

Useonly originalreplacement partsforany repairor component

replacement. Consult the list of replacement parts that

corresponds to the specication of the original equipment.

Do not drain water circuits containing industrial brines,

without informing the technical service department at the

installation site or a competent body rst.

Close the entering and leaving water shutoff valves and

purge the unit water circuit,before working on the components

in

stalled on the circuit (screen lter, pump,water ow switch,

etc.).

Periodically inspect all valves, ttings and pipes of the

refrigerant and hydronic circuits to ensure that they do not

show any corrosion or any signs of leaks.

It is recommended to wear ear defenders,when working near

the unit and the unit is in operation.