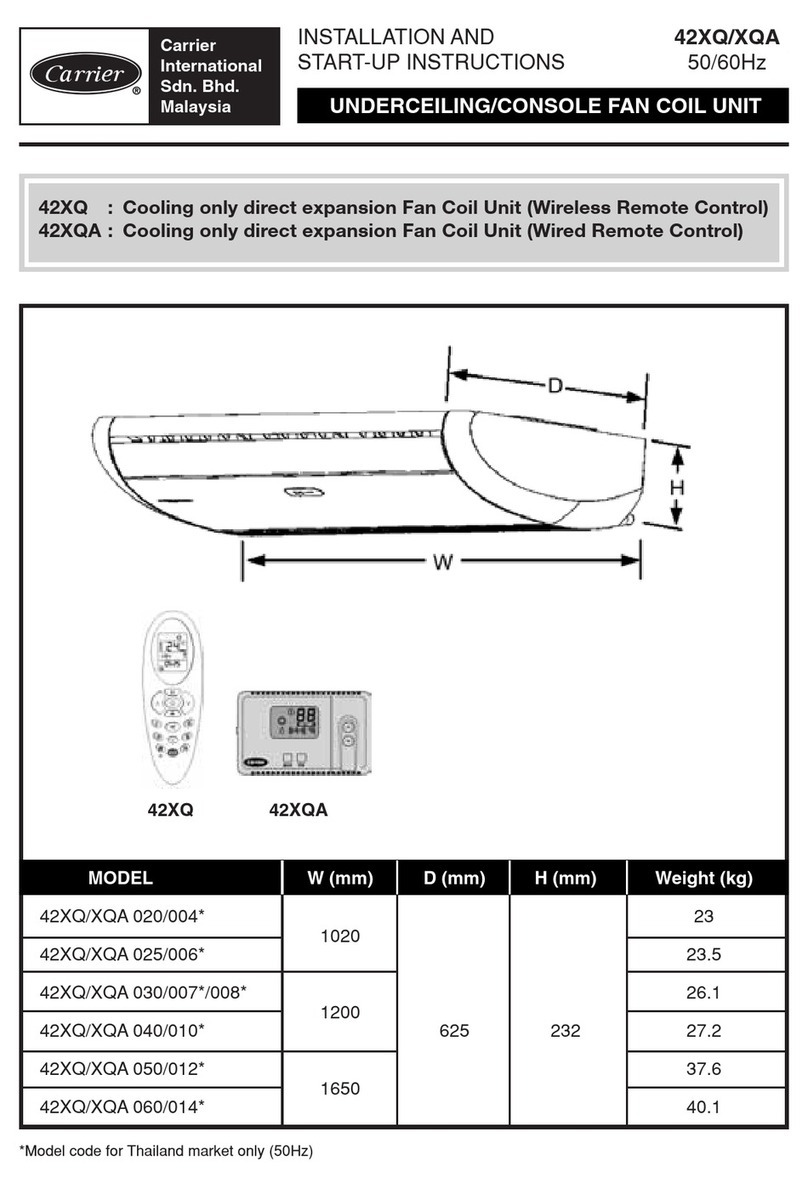

Fig. 2—38BRC060 208/230v, 1 Phase, 60 Hertz A98017

CH (NOTE #9)

RED or BLK BLK

208/230 1Ø

POWER

SUPPLY

L1

L2

EQUIP

GND

CONT

11 21

13 23 YEL

OFM

YEL

COMP BLU

BRN

BRN

YEL

S

C

RYEL

YEL

BLU BLU

BRN

*SC

BLK

BLK

*ST

*SR

12

5

CAP

*LPS

*DTS

*HPS BLK BLK YE

L

BLU

VIO

H

C

F

CONNECTION DIAGRAM

+t°

BLU

BLK

BLU YE

L*CTD

BRN

(NOTE #14)

BLU

BLU BLK *LLS BLK

Y RG

INDOOR THERMOSTAT (NOTE #5) INDOOR BLOWER MOTOR

EXTERNAL POWER

SUPPLY 24V

(NOTES #3 & #6)

(NOTE #8)

FACTORY POWER WIRING

FACTORY CONTROL WIRING

FIELD CONTROL WIRING

FIELD POWER WIRING

COMPONENT CONNECTION

FIELD SPLICE

JUNCTION

CONT CONTACTOR

CAP CAPACITOR (DUAL RUN)

*CH CRANKCASE HEATER

*CHS CRANKCASE HEATER SWITCH

COMP COMPRESSOR

*CTD COMPRESSOR TIME DELAY

*DTS DISCHARGE TEMP. SWITCH

*HPS HIGH PRESSURE SWITCH

IFR INDOOR FAN RELAY

*LLS LIQ. LINE SOLENOID VALVE

*LPS LOW PRESSURE SWITCH

OFM OUTDOOR FAN MOTOR

*SC START CAPACITOR

*SR START RELAY

*ST START THERMISTOR

* MAY BE FACTORY OR FIELD

INSTALLED.

-LEGEND-

SCHEMATIC DIAGRAM

(LADDER FORM)

11 21

CONT

L1

QUIP

GND *SR

*SC

52

1H

C

F

*ST

OFM

+t°CONT

23 13

CAP

S

CRCOMP

L2

*LPS

*DTS

*HPS CONT

IFR

EXTERNAL POWER SUPPLY 24 V

*CTD

(NOTE #14)

Y

G

R

OOR THERMOSTAT

RC

*CH

-NOTES-

1. Symbols are electrical representation only.

2. Compressor and fan motor furnished with inherent thermal

protection.

3. To be wired in accordance with National Electric N.E.C.

and local codes.

4. N.E.C. class 2, 24 Vcircuit, min. 40 VA required, 60VA on

units installed with LLS.

5. Use copper conductors only.

6. Connection for typical cooling onlythermostat, for other

arrangements, see installation instructions.

7. If indoor section has a transformer with a grounded

secondary, connect the grounded side to the BRN lead.

8. When start relay andstart capacitor areinstalled, start

thermistor is not used.

9. CH not used on all units.

10.If any of the original wire, as supplied, must be replaced,

use the same or equivalent wire.

11.Check all electrical connections inside control box for

tightness.

12.Do not attempt to operate unit until service valves have

been opened.

13.Do not rapid cycle compressor. Compressor must be off

3 minutes to allow pressures to equalize between high

and low side before starting.

14.Wire not present if HPS, LPS, DTSor CTD are used.

15.Use conductors suitable for at least 75°C (167°F).

324474-101 REV. A

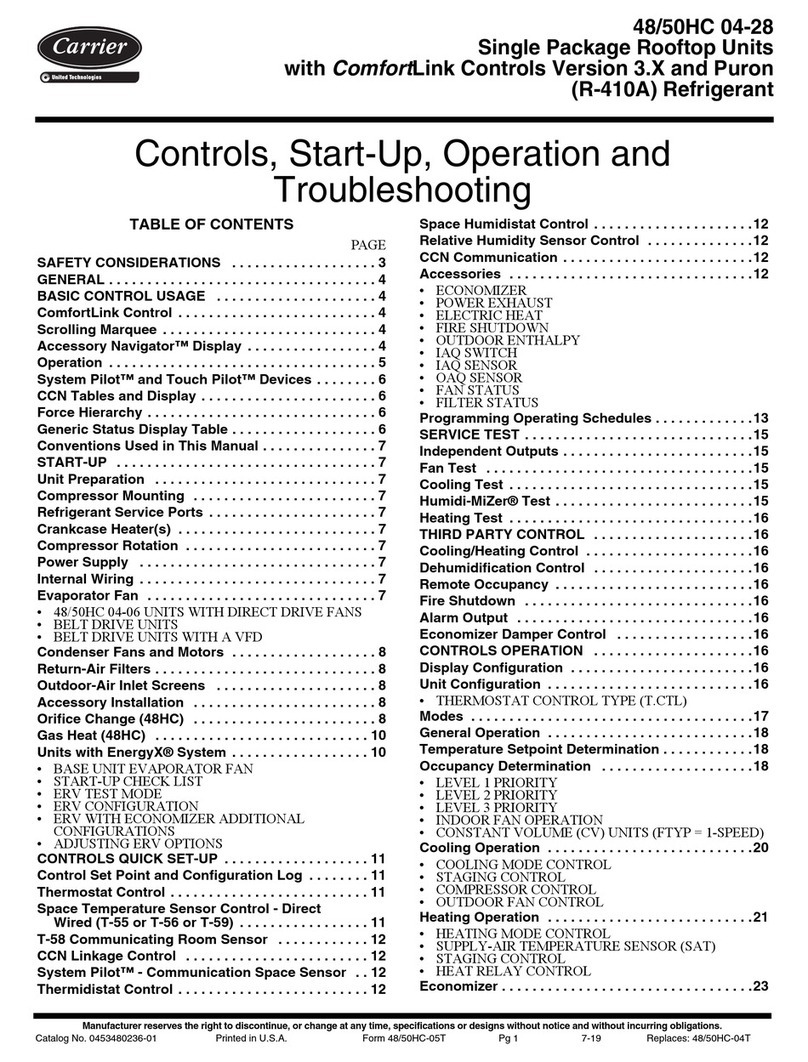

. Compressor damage may occur if system is over charged.

. This unit is factory charged with R-22 in accordance with the amount shown on the rating plate. The charge is

adequate for most systems using matched coils and tubing not over 15 feet long. The best performance will be

achieved when the unit operates with a suction gas superheat at the compressor inlet of 5 °F at normal rating

conditions of the air conditioning and refrigeration institute (ARI). This chart may be used to approximate the

charge if ARI rating conditions cannot be obtained. ARI rating conditions are equivalent to DOEtest "A"

conditions. See product data literature for required indoor air flow rates and for use of line lengths over 15 Ft.

. Carefully relieve refrigerant pressure within this unit before final disposal.

CAUTION

LOGIC

T1 T3

T2

IFR

C

R

*LLS

LOGIC

T1 T3

T2

*CHS

RED or BLK BLK

*CHS

2