1

Installation Instructions

Read these instructions completely before attempting to install the

Vertical EconoMi$er X Accessory.

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . .1

GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

EconoMi$er X Sensor Usage . . . . . . . . . . . . . 2

ACCESSORIES LIST. . . . . . . . . . . . . . . . . . . . .2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 2-5

EconoMi$er X Standard Sensors . . . . . . . . . .5

EconoMi$er X Control Modes . . . . . . . . . . 5-11

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . 13

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance, or

use can cause explosion, re, electrical shock or other conditions which

may cause personal injury or property damage. Consult a qualied

installer, service agency, or your distributor or branch for information or

assistance. The qualied installer or agency must use factory-authorized

kits or accessories when modifying this product. Refer to the individual

instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloths for brazing operations and have a re extinguisher

available. Read these instructions thoroughly and follow all warnings

or cautions attached to the unit. Consult local building codes and

appropriate national electrical codes (in USE, ANSI/NFPA70, National

Electrical Code (NEC); in Canada, CSA C22.1) for special requirements.

It is important to recognize safety information. This is the safety-alert

symbol . When you see this symbol on the unit and in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, CAUTION, and

NOTE. These words are used with the safety-alert symbol.

DANGER identies the most serious hazards which will result in severe

personal injury or death. WARNING signies hazards which could

result in personal injury or death.

CAUTION is used to identify unsafe practices, which may result in

minor personal injury or product and property damage.

NOTE is used to highlight suggestions which will result in enhanced

installation, reliability, or operation.

GENERAL

The EconoMi$er X system utilizes the latest technology available

for integrating the use of free cooling with mechanical cooling for

packaged rooftop units. The solid-state control system optimizes energy

consumption, zone comfort, and equipment cycling by operating the

compressors when the outdoor-air temperature is too warm, integrating

the compressor with outdoor air when free cooling is available, and

locking out the compressor when outdoor-air temperature is too cold.

Demand control ventilation is supported.

Units displaying 17th position of the model number to indicate that the

unit is equipped with the factory-installed VFD (Variable Frequency

Drive) option for 2-speed indoor fan control. The VFD option is required

for units equipped with EconoMi$er X. For detailed information on the

VFD see the Variable Frequency Drive (VFD) Installation, Setup and

Troubleshooting Supplement.

The EconoMi$er X system utilizes gear-drive technology with a direct-

mount spring return actuator that will close upon loss of power. The

EconoMi$er X system comes standard with an outdoor air temperature

sensor, mixed air temperature sensor. Outdoor enthalpy, indoor enthalpy,

and CO2 sensors are available for eld installation. See Table 3 for

sensor usage.

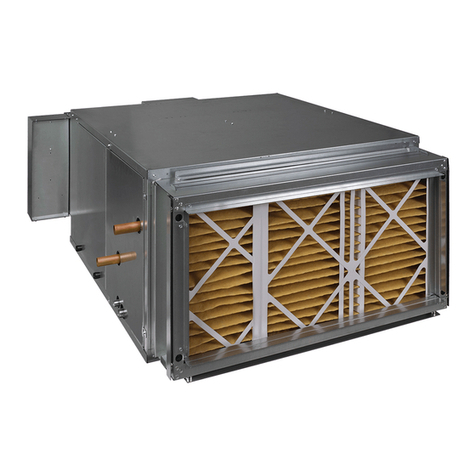

IMPORTANT: The economizer outside air dampers meet the ASHRAE

90.1 leakage requirements. Economizer must be installed perfectly

square to avoid damper leakage. Squareness tolerance +/- 1/32”.

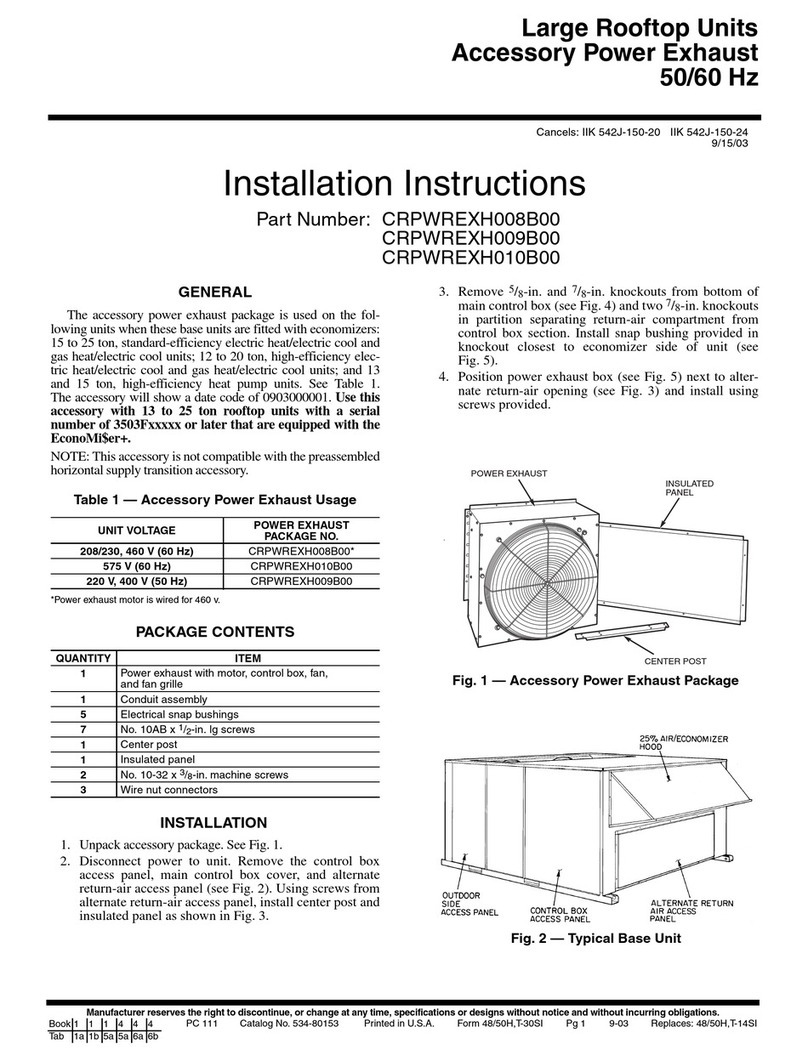

Standard barometric relief dampers provide natural building pressurization

control. An optional power exhaust system is available for applications

requiring even greater exhaust capabilities. The power exhaust set point

is adjustable at the EconoMi$er X controller.

See Table 1 for package usage. See Table 2 for package contents. See

Table 3 for sensor usage.

ACCESSORIES LIST

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could cause personal injury or death.

Before performing service or maintenance operations on the unit,

always turn off main power switch to unit and install lock(s) and

lockout tag(s). Unit may have more than one power switch. Ensure

electrical service to rooftop unit agrees with voltage an amperage

listed on the unit rating plate.

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing, safety glasses and gloves when

handling parts and servicing roof top units.

!

!

Table 1 - Package Usage

Table 2 - Package Contents

UNIT SIZE PART NUMBER

Small Cabinet,

Footprint size: 46 3/4” x 74 3/8” CRECOMZR067A02

Large Cabinet,

Footprint size: 58 1/2” x 88 1/8” CRECOMZR069A03

Extra-Large Cabinet,

Footprint size: 63 3/8” x 115 7/8” CRECOMZR071A00

PACKAGE NO. QTY CONTENTS

CRECOMZR067A00,

CRECOMZR069A00

1

1

1

18

1

1

Hood Top and Sides

Hood Divider

Aluminum Filter

Screws

EconoMi$er X Assembly

Mixed Air Temperature Sensor

CRECOMZR071A00

1

1

1

2

1

1

1

Hood Top and Sides

Hood Divider

Hood Filter Divider

Aluminum Filters

Hardware Bag

EconoMi$er X Assembly

Mixed Air Temp Sensor

Small Rooftop Products

3 to 12 ½ Tons

Vertical EconoMi$er X Accessory

CRECOMZR067A00

CRECOMZR069A00

CRECOMZR071A00

!