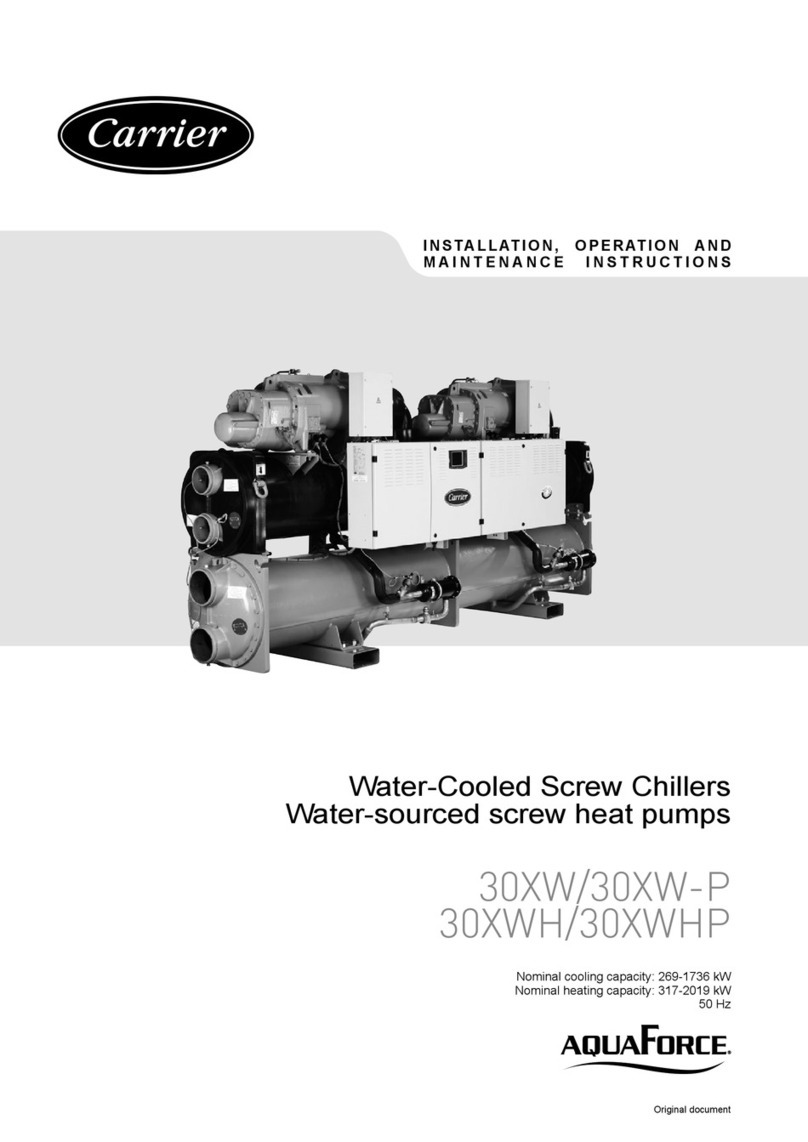

12 - HYDRAULIC CONNECTIONS

AQUASNAP 30WI 700V 800V 900V 1000V 1100V 1200V 1400V 1600V 1800V 2100V 2400V

Chilled water inlet/outlet BCDiameter DN 100 PN 16 -

VICTAULIC DN 125 PN 16 - VICTAULIC DN 150 PN 16

VICTAULIC

Cooling water inlet/outlet

DEDiameter DN 100 PN 16 -

VICTAULIC DN 125 PN 16 - VICTAULIC DN 150 PN 16

VICTAULIC

Hydraulic connections must be made in accordance with the

diagram delivered with the unit. This diagram shows the positions

and dimensions of the water inlets and outlets on the exchangers.

Follow the requirements below when making these connections:

-Ensure the inlet and outlet pipes are connected in the

direction shown on the unit.

-In order to meet the operating conditions (ow rates, pressure

loss), a sizing calculation must be performed. The diameter

of the pipes may therefore be different to that specied on

the exchanger.

-The pipes and tubes should not transmit any axial or radial

forces to the exchangers or any vibrations.

-The water must be analysed and, if necessary, treated (we

recommend contacting a qualied water treatment specialist).

The analysis will reveal whether the water is suitable for use with

the various materials it will come into contact with and prevent the

formation of electrolytic couples:

• 99.9% copper tubes brazed with copper and silver

• Threaded bronze couplings or at steel anges, depending

on the unit model

• Plate heat exchangers and AISI 316 - 1.4401 stainless steel

connections brazed with copper and silver

-The water circuit must have as few bends and horizontal

sections at different levels as possible.

-Install shut-off valves near the water inlets and outlets in order

to isolate the exchangers.

-Install manual or automatic air bleed valves at the high points

of the circuit(s).

-The manual or automatic air bleed valves tted on the

machine are not intended to be used to bleed the rest of the

hydraulic circuit.

-A static pressure of 1 bar must be maintained at all times

(machine and pump off or on) on the pump intake.

-Install drain connections at all circuit low point(s).

-Install the accessories that are essential for any hydraulic

circuit (balancing valves, expansion vessel, safety valve,

thermometer pockets, etc.).

-Insulate the pipes and tubes (after performing leak tests) in

order to reduce heat losses and prevent damage from frost.

-Install heating elements on all pipes that could be exposed

to frost.

-The installer must provide the necessary systems for lling

and draining the energy transfer uid.

-To keep the pressure in the coolant circuit below the intended

operating pressure, avoid introducing static or dynamic

pressure into the circuit.

IMPORTANT:

-To prevent any risk of fouling or damage to the plate heat

exchangers (evaporator and condenser), it is essential to t

a strainer to the water inlets as close as possible to the

exchangers and in a place which is easily accessible for

disassembly and cleaning. The maximum mesh size of this

lter should be 800 μm.

-Flexible couplings must be used on the hydraulic pipework

(evaporator and condenser).

The system pipework must be secured to the wall of the building

and must not place any additional load on the unit.

-Using untreated or incorrectly treated water may cause

corrosion or erosion or the formation of scale, algae or sludge

deposits. CARRIER shall not be held liable for damage

resulting from the use of untreated or incorrectly treated water,

or of saline or brackish water.

When the unit is used as a heat pump, the maximum water

return temperature of the installation will be 55°C. Never

series-connect the condenser with a high-temperature water

network (boiler). Doing so will result in damage.

NOTE: The maximum operating pressure on the water side should

be 10 bar (evaporator and condenser). The water ow sensor is

supplied tted to the unit. Stopping the pumps will automatically

cause the unit to stop to avoid any risk of freezing. The pump

or pumps must be slaved to the refrigeration unit (auxiliary

operation switch of the pump to be wired).If the hydraulic circuit

is drained for a period of more than one month, ll the entire

circuit with nitrogen to prevent any risk of corrosion.

IMPORTANT :

If antifreeze is not added to the circuit and the unit is not operated

during periods of freezing weather, drain the evaporator and the

outside pipes.

10