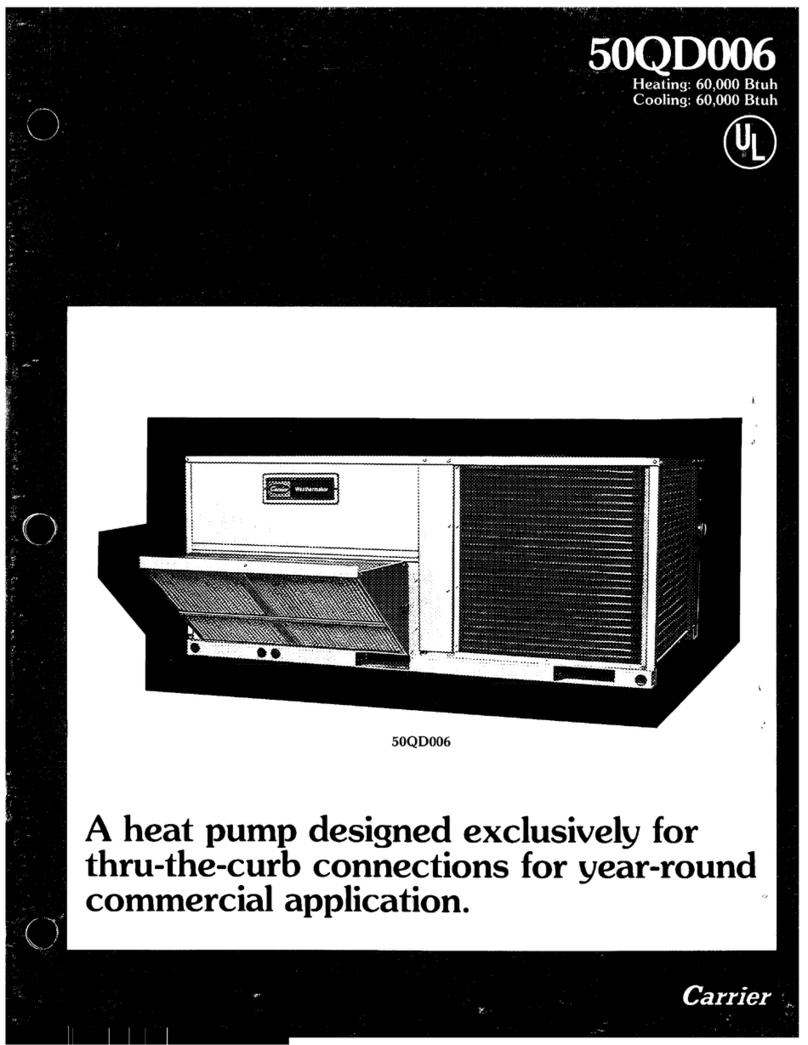

Source Connections

(Boiler/Tower/Ground)

Control

Wiring

Load Connections (Hot

Water/Chilled Water) Automatic Flow

Regulator

Valve

with Pressure

Temperature Port

..............Ball Valve

,_ with Pressure

emperature Port

e Y Strainer with

Blow Down Valve

/' Power

Disconnect

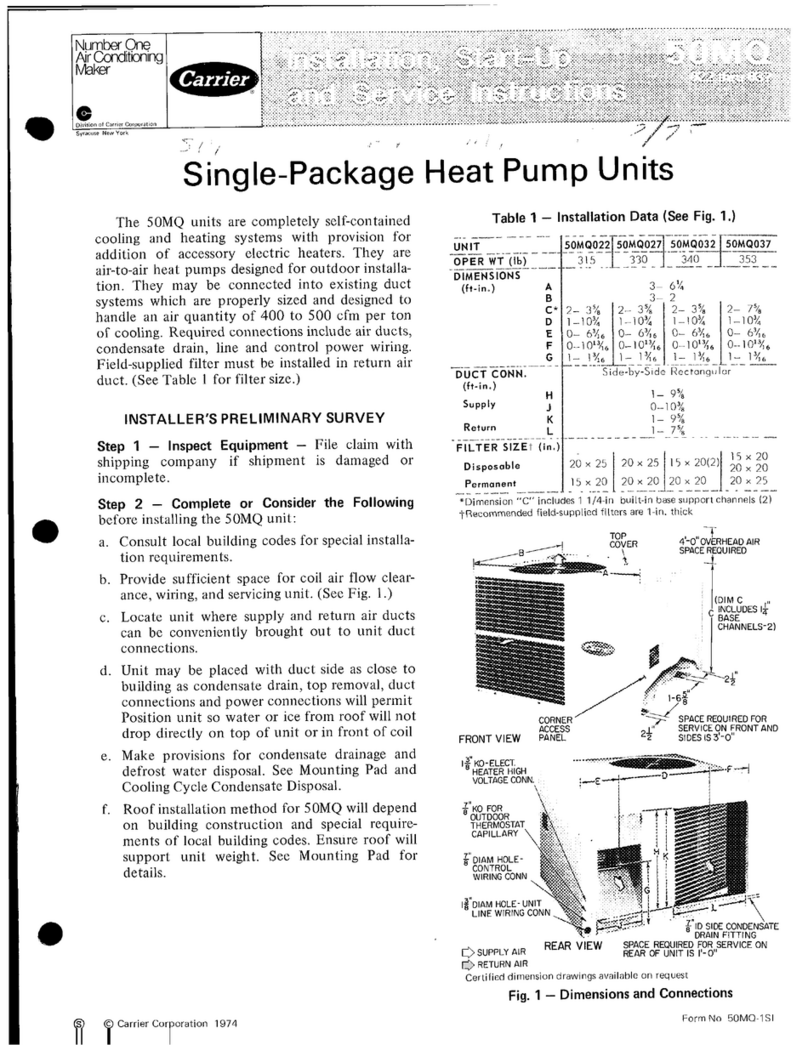

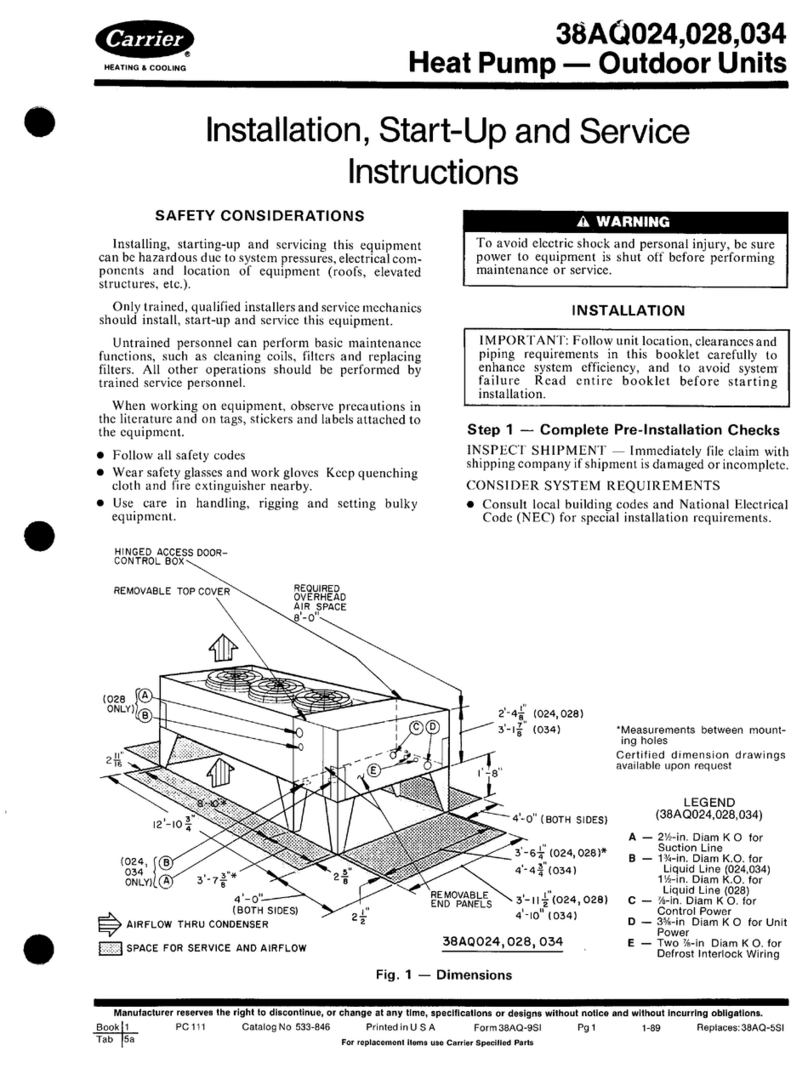

Fig. 3 -- Typical Water Loop System --

Boiler, Tower, or Ground (Sizes 180,360 Shown)

Step 5 EConnect Piping EDepending on the appli-

cation, there are 3 types of WSHP piping systems to choose

from: water loop, ground-water and ground loop. Refer to the

Carrier System Design Manual for additional information.

All WSHP units utilize low temperature soldered female

pipe thread fittings for water connections to prevent annealing

and out-of-round leak problems which are typically associated

with high temperature brazed connections. When making pip-

ing connections, consider the following:

• A backup wrench must be used when making screw con-

nections to unit to prevent internal damage to piping.

• Insulation may be required on piping to avoid condensa-

tion in the case where fluid in loop piping operates at

temperatures below dew point of adjacent air.

• Piping systems that contain steel pipes or fittings may

be subject to galvanic corrosion. Dielectric fittings may

be used to isolate the steel parts of the system to avoid

galvanic corrosion.

• Units may be manifolded together via top water connects

to get increased temperatures, when piped in series, or

greater capacity, when piped in parallel.

WATER SUPPLY AND QUALITY -- Check water supply.

Water supply should be plentiful and of good quality. See

Table 2 for water quality guidelines.

IMPORTANT: Failure to comply with the above required

water quality and quantity limitations and the closed-

system application design requirements may cause damage

to the robe-in-robe heat exchanger that is not the responsi-

bility of the manufacturer.

In all applications, the quality of the water circulated

through the heat exchanger must fall within the ranges listed in

the Water Quality Guidelines table. Consult a local water treat-

ment firm, independent testing facility, or local water authority

for specific recolranendations to maintain water quality within

the published lhnits.

WATER LOOP APPLICATIONS -- Water loop applica-

tions usually include a number of units plumbed to a colmnon

piping system. Maintenance to any of these units can introduce

air into the piping system. Therefore, air elimination

equipment comprises a major portion of the mechanical room

plumbing.

The flow rate is usually set between 2.25 and 3 gpm per ton

of cooling capacity. For proper maintenance and servicing,

pressure-temperature (P/T) ports are necessary for temperature

and flow verification.

In addition to complying with any applicable codes, consid-

er the following for system piping:

• Piping systems utilizing water temperatures below

50 F require 1/2-in. closed cell insulation on all piping

surfaces to eliminate condensation.

• All plastic to metal threaded fittings should be avoided

due to the potential to leak. Use a flange fitted substitute.

• Teflon* tape thread sealant is recommended to minimize

internal fouling of the heat exchanger.

• Use backup wrench. Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• The piping system should be flushed prior to operation to

remove dirt and foreign materials from the system.

GROUND-WATER APPLICATIONS -- In addition to

complying with any applicable codes, consider the following

for system piping:

• Install shut-off valves for servicing.

• Install pressure-temperature plugs to measure flow and

temperature.

• Boiler drains and other valves should be connected using

a "T" connector to allow acid flushing for the heat

exchanger.

• Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• Use PVC SCH80 or copper piping material.

NOTE: PVC SCH40 should not be used due to system high

pressure and temperature extremes.

GROUND-LOOP APPLICATIONS -- Temperatures be-

tween 25 and 110 F and a cooling capacity of 2.25 to 3 gpm of

flow per ton are recolmnended. In addition to complying with

any applicable codes, consider the following for system piping:

• Piping materials should be limited to only polyethylene

fusion in the buried sections of the loop.

• Galvanized or steel fittings should not be used at any

time due to corrosion.

• All plastic to metal threaded fittings should be avoided

due to the potential to leak. Use a flange fitted substitute.

• Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• Pressure-temperature (P/T) plugs should be used to mea-

sure flow of pressure drop.

UNIT LOAD PIPING -- For applications with wide temper-

amre variation such as heating/cooling coils:

• Use piping materials that are rated for the maximum tem-

perature and pressure combination. This excludes PVC

for most heating applications.

• Ensure load water flow in high temperature heating

applications is at least 3 gpm per ton to improve perfor-

mance and reduce nuisance high pressure faults.

• DO NOT employ plastic to metal threaded joints.

• Utilize a pressure tank and air separator vent system to

equalize pressure and remove air.

• Employ an 800-micron particulate strainer in both load

and source plumbing to protect the plate heat exchanger.

Swilmnin_ Pool Hot Tub Applications -- Load heat ex-

changer should be isolated with secondary heat exchanger

constructed of anti-corrosion material in all chlonne/bromine

fluid applications.

Potable Water Applications

• Load coax material should always be vented double

walled for use in potable water systems.

• Ensure load water flow in high temperature heating

applications is at least 3 gpm per ton to improve perfor-

mance and reduce nuisance high pressure faults.

*Teflon is a trademark of E. I. du Pont de Nemours and Company.