SAFETY CONSIDERATIONS

Installation and servicing of this equipment can be hazardous due to

mechanical and electrical components. Only trained and qualified

personnel should install, repair, or service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning and replacing air filters. All other operations nmst be

performed by trained service personnel. When working on this

equipment, observe precautions in the literature, on tags. and on la-

bels attached to or shipped with the unit and other safety precautions

that may apply.

Follow all safety codes. Installation nmst be in compliance with lo-

cal and national building codes. Wear safety glasses, protective

clothing, and work gloves. Have fire extinguisher available. Read

these instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit.

Recognize safety information. This is the safety-alert symbol/_

When you see this symbol on the unit and in instructions or manuals.

be alert to the potential for personal injury.

Understand these signal words: DANGER. WARNING. and CAU-

TION and NOTE. These words are used with the safety-alert sym-

bol. DANGER identifies the most serious hazards which will result

in severe personal injury or death. WARNING signifies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices which may result in minor personal in-

jury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

Note: Installer: This manual should be left with the equipment user.

FOR YOUR SAFETY

Failure to follow this caution may result in personal injury.

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

FIRE, EXPLOSION, ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Do not use this unit if any part has been under water.

Immediately call a qualified service technician to inspect the

unit and to replace any part of the control system which has

been under water.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

When removing access panels or performing maintenance

functions inside your unit, be aware of sharp sheet metal parts

and screws. Although special care is taken to reduce sharp

edges to a minimum, be extremely careful when handling

parts or reaching into the unit.

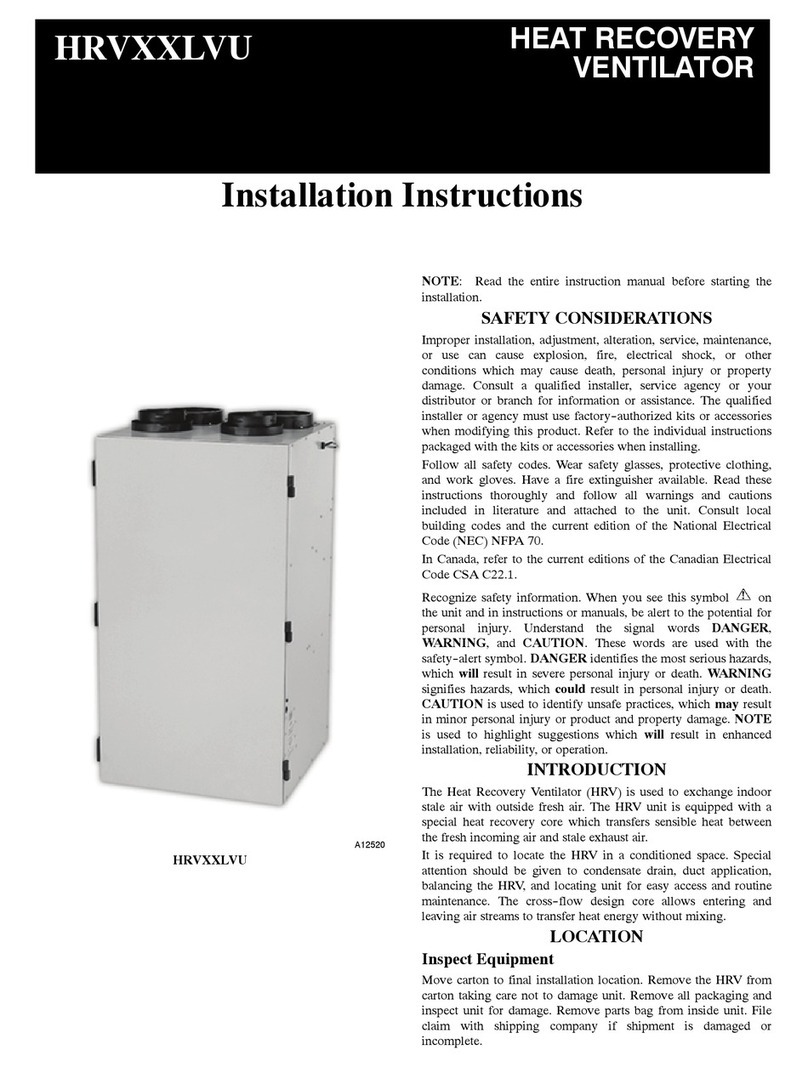

UNIT INTRODUCTION

This 48CE unit is a small packaged gas heat/electric cooling system

that can utilize the comfort of gas heating packaged along with effi-

cient electric air conditioning. This unit uses Puron, the environ-

mentally friendly refrigerant, for cooling.

Starting or Shutting Unit Off

To start the unit:

1. Turn on the electrical power supply to unit.

2. Select temperature and set MODE control to desired mode.

To shut unit off:

Note: If the unit is being shut down because of a malfunction, call

your dealer as soon as possible.

1. Set system MODE control to OFF.

2. Turn off the electrical power supply to unit.

OPERATING YOUR UNIT

The operation of your unit is controlled by the Infinity User Inter-

face (UI). You simply program the UI and it maintains the indoor

temperature at the level you select. See UI manual for detailed in-

structions.

To better protect your investment and to eliminate unnecessary ser-

vice calls, familiarize yourself with the following facts:

Step 1--Cooling Mode

With the SYSTEM or MODE control set to COOL, your unit will

run in cooling mode until the indoor temperature is lowered to the

level you have selected. On extremely hot days. your unit will run

for longer periods at a time and have shorter "off' periods than on

moderate days.

Step 2--Gas Heating Mode

With the SYSTEM or MODE control set to HEAT, your unit will

run in heating mode until the room temperature is raised to the level

you have selected. Of course, your unit will run for longer periods

to maintain a comfortable environment on cooler days and nights

than on moderate ones.

MAINTENANCE AND SERVICE

This section discusses maintenance that should be performed on

your system. Most maintenance should be performed by your deal-

er. You, as the owner, may wish to handle some minor maintenance

for your new unit.

Routine Maintenance

All routine maintenance should be handled by skilled, experienced

personnel. Your dealer can help you establish a standard procedure.

To assure proper functioning of the unit. flow of condenser air nmst

not be obstructed from reaching the unit. Clearance from the top of

the unit is 48 in. Clearance of at least 36 in. is required on sides ex-

cept the power entry side (42 in. clearance) and the duct side (12 in.

minimum clearance).

Maintenance and Care for the Equipnlent Owner

Before proceeding with those things you might want to maintain

yourself, please carefully consider the following: