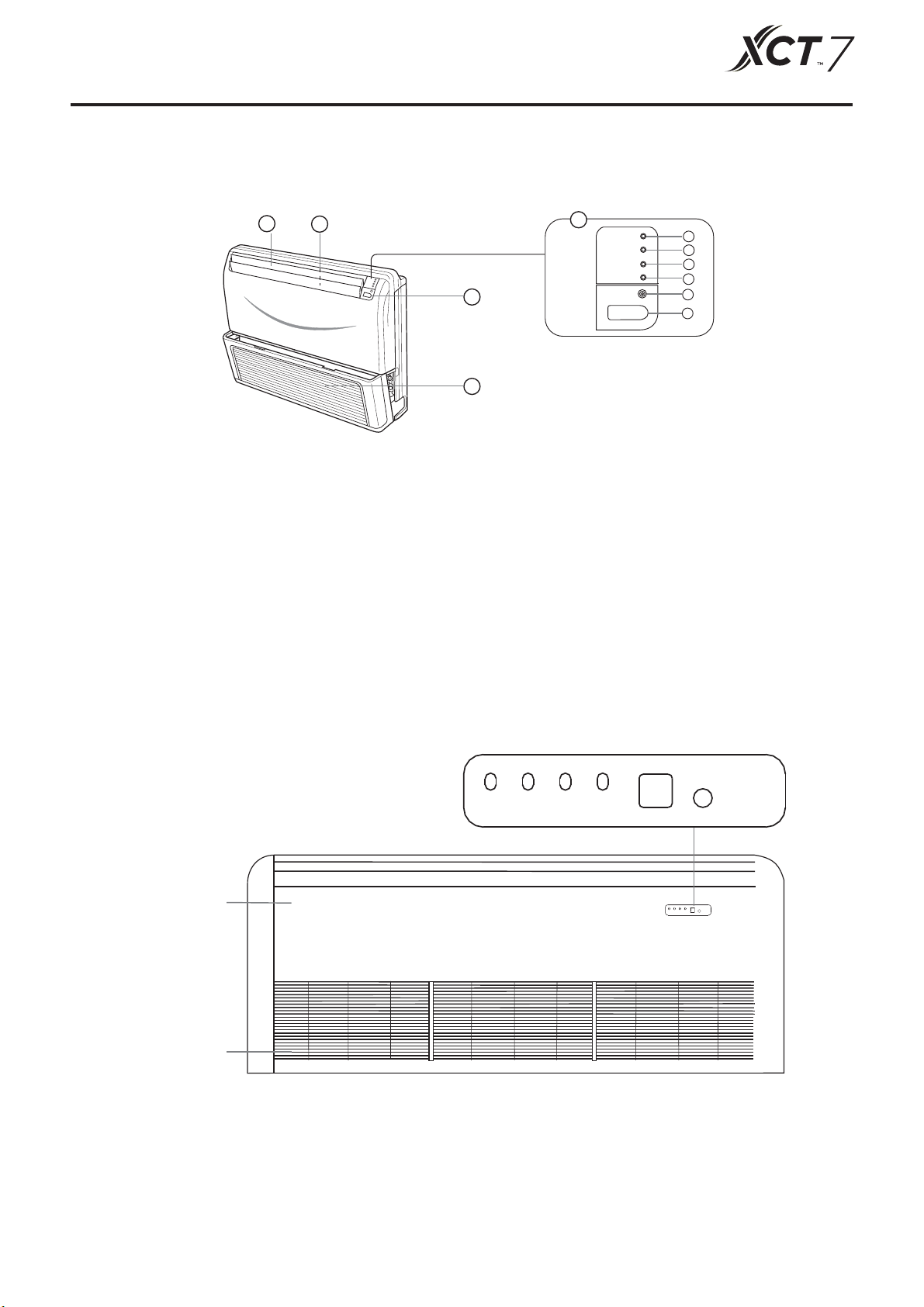

Carrier XCT 7 40VC009-048F-7G-QEE Installation instructions

Other Carrier Heat Pump manuals

Carrier

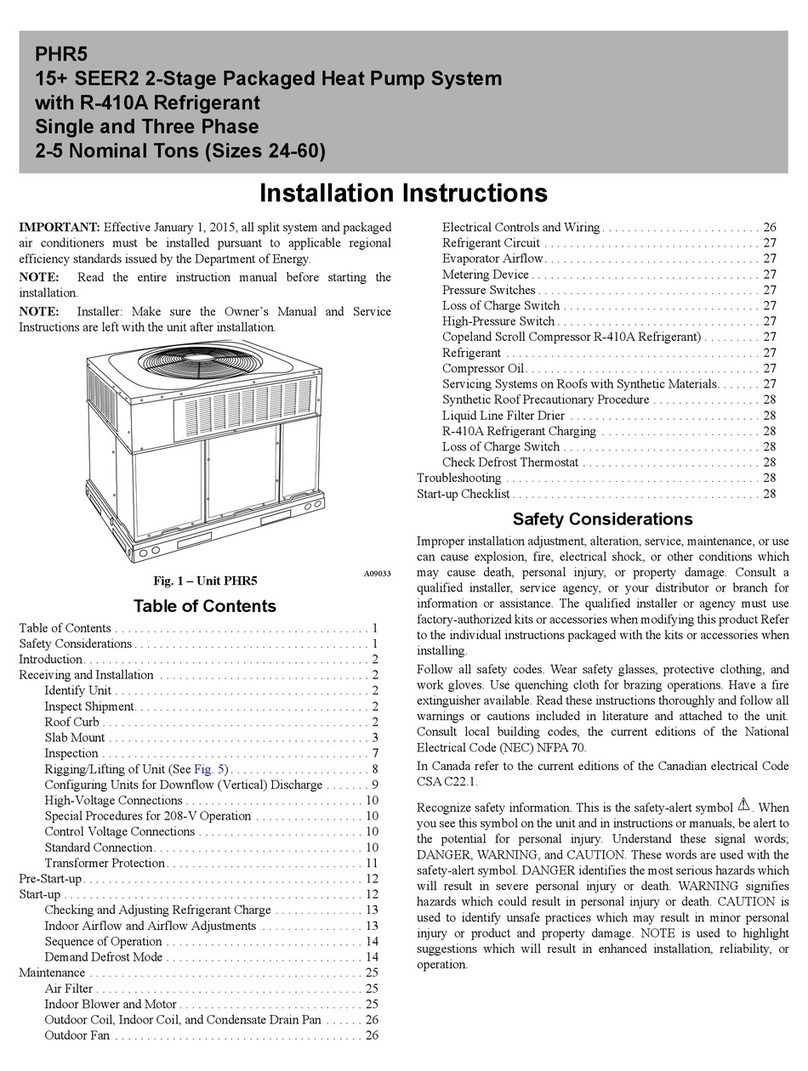

Carrier PHR5 User manual

Carrier

Carrier 50ZHK Instruction Manual

Carrier

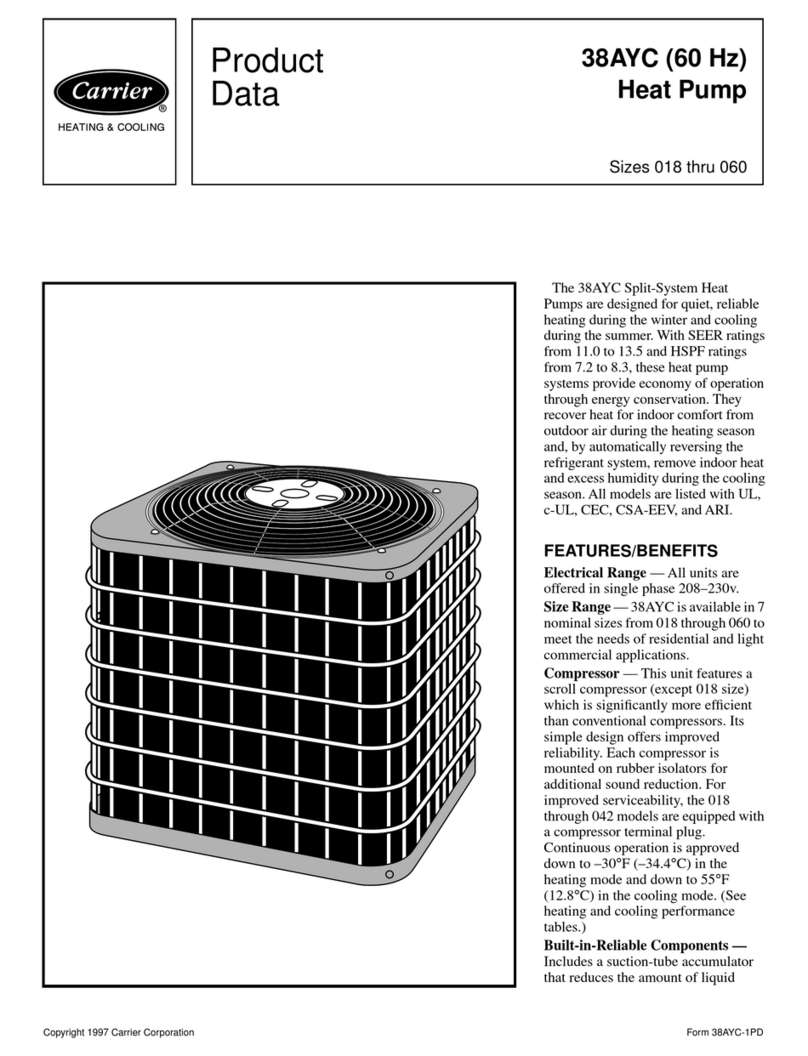

Carrier 38AYC Series Operation manual

Carrier

Carrier 38EYG Instructions and recipes

Carrier

Carrier Performance 50VT Operation manual

Carrier

Carrier 50JZ-A Instruction Manual

Carrier

Carrier 25hba User manual

Carrier

Carrier 38AUQ Dimensions and installation guide

Carrier

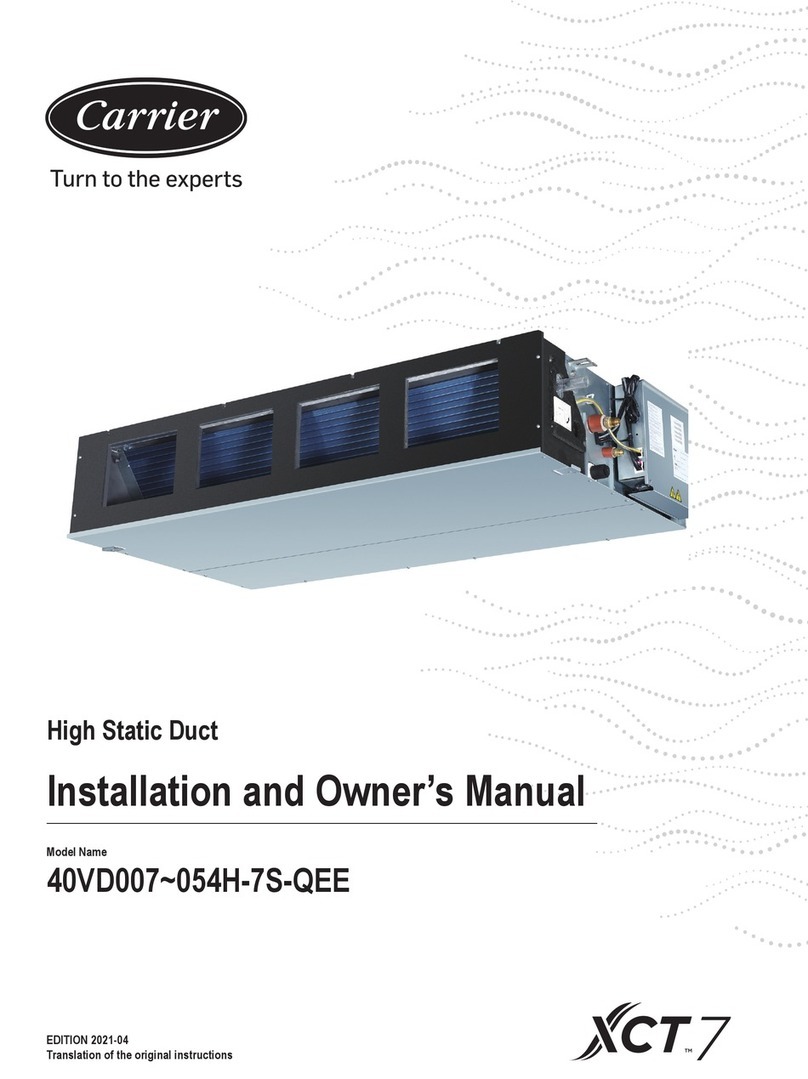

Carrier XCT 7 40VD H-7S Series Installation instructions

Carrier

Carrier 40MBD Series User manual

Carrier

Carrier 38AC012 Manual

Carrier

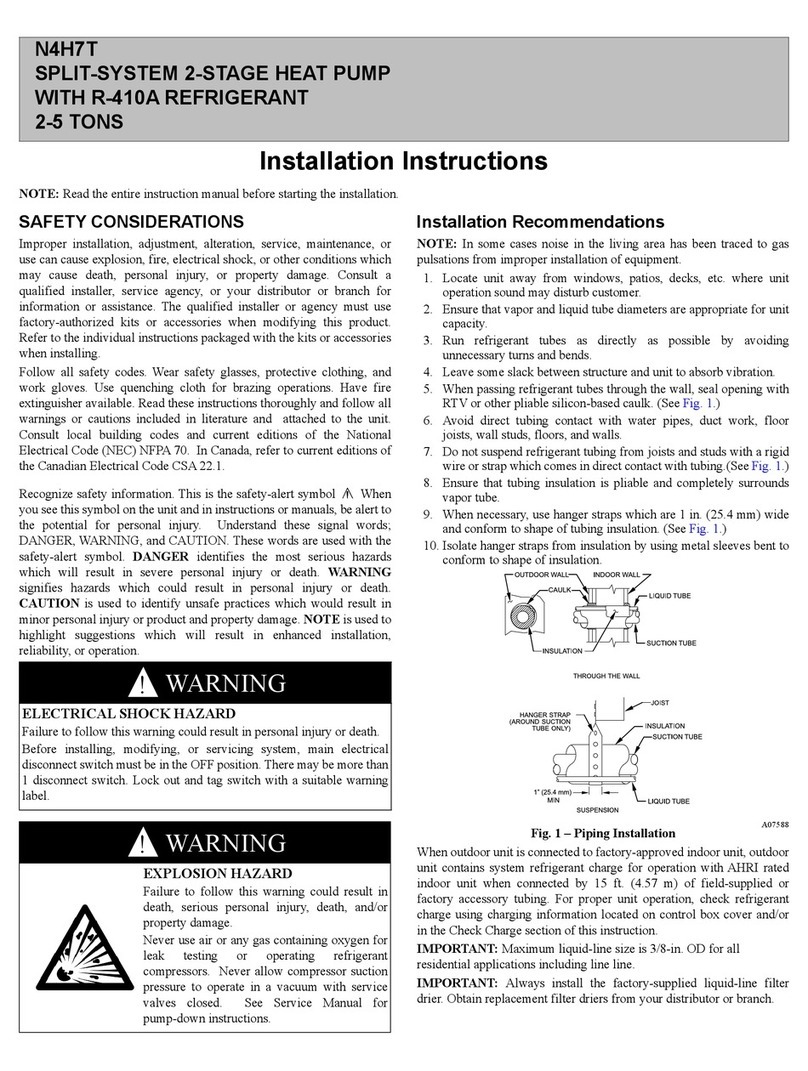

Carrier N4H7T User manual

Carrier

Carrier Comfort 50VT-K User manual

Carrier

Carrier 50YQ Dimensions and installation guide

Carrier

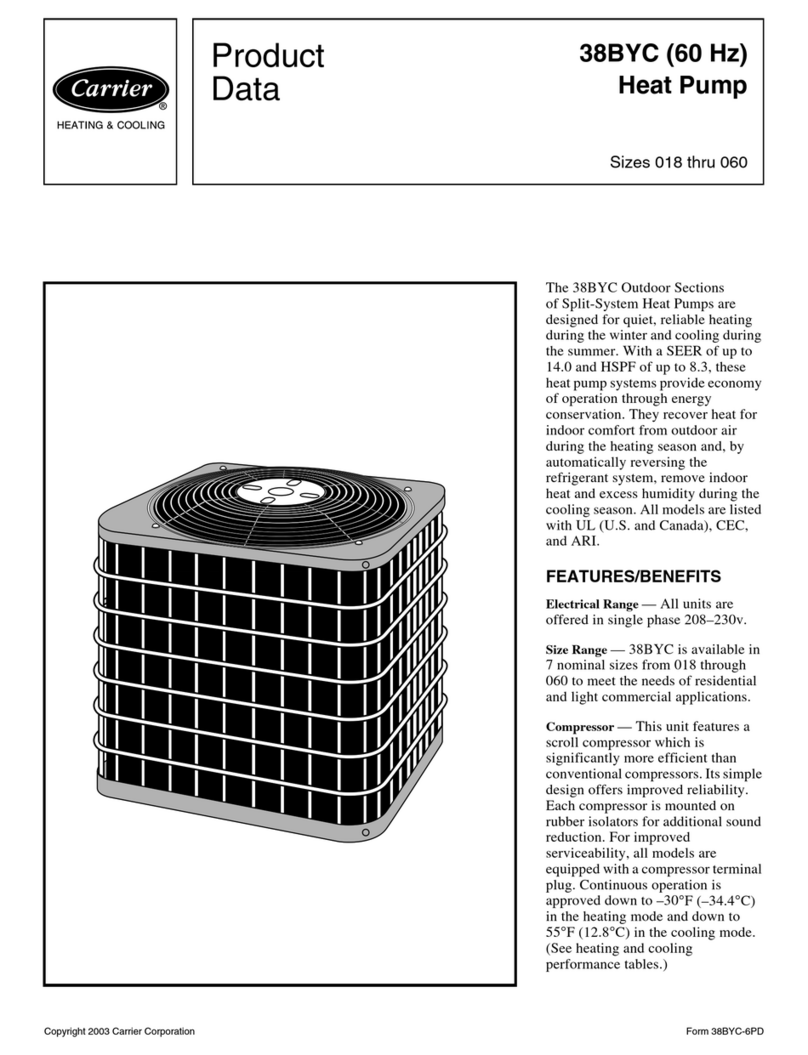

Carrier 38BYC Series Operation manual

Carrier

Carrier AquaForce PUREtec 30XW-VZE 451 Manual

Carrier

Carrier AquaSnap Plus 30AWH004HB User manual

Carrier

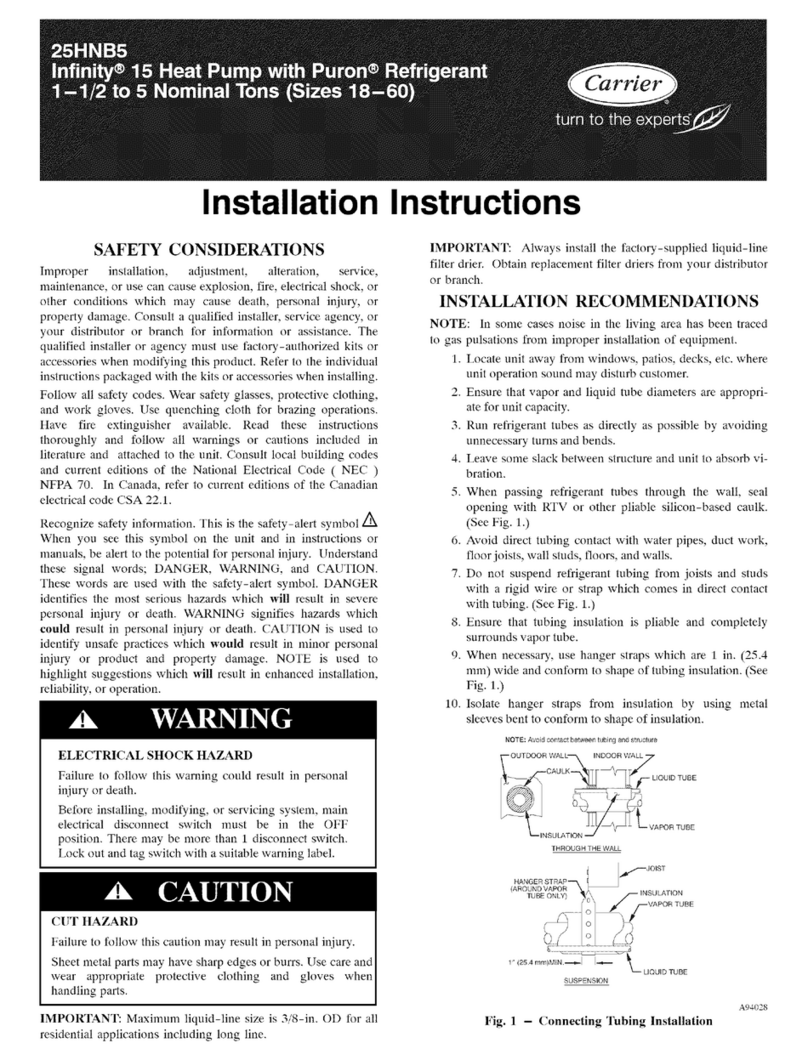

Carrier 25HNB5 User manual

Carrier

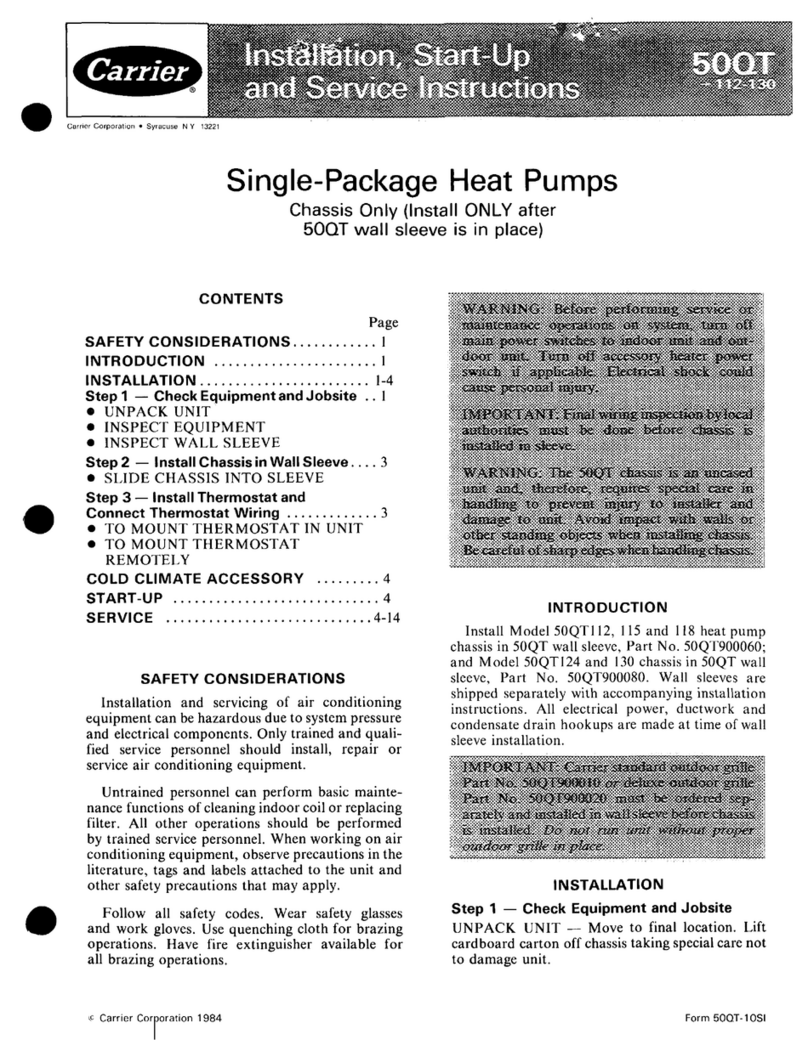

Carrier 50QT Dimensions and installation guide

Carrier

Carrier WEATHERMAKER 50TFQ008 Dimensions and installation guide

Popular Heat Pump manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PUZ-SWM60VAA Service manual

Dimplex

Dimplex LI 16I-TUR Installation and operating instruction

TGM

TGM CTV14CN018A Technical manual

Kokido

Kokido K2O K880BX/EU Owner's manual & installation guide

Viessmann

Viessmann VITOCAL 300-G PRO Type BW 2150 Installation and service instructions

Viessmann

Viessmann KWT Vitocal 350-G Pro Series Installation and service instructions for contractors

Ariston

Ariston NIMBUS user manual

Weishaupt

Weishaupt WWP L 7 Installation and operating instruction

GE

GE Zoneline AZ85H09EAC datasheet

Bryant

Bryant Preferred Series installation instructions

Daikin

Daikin altherma EJHA04AAV3 installation manual

Bryant

Bryant 549B Series Installation, Start-Up and Service Instructions