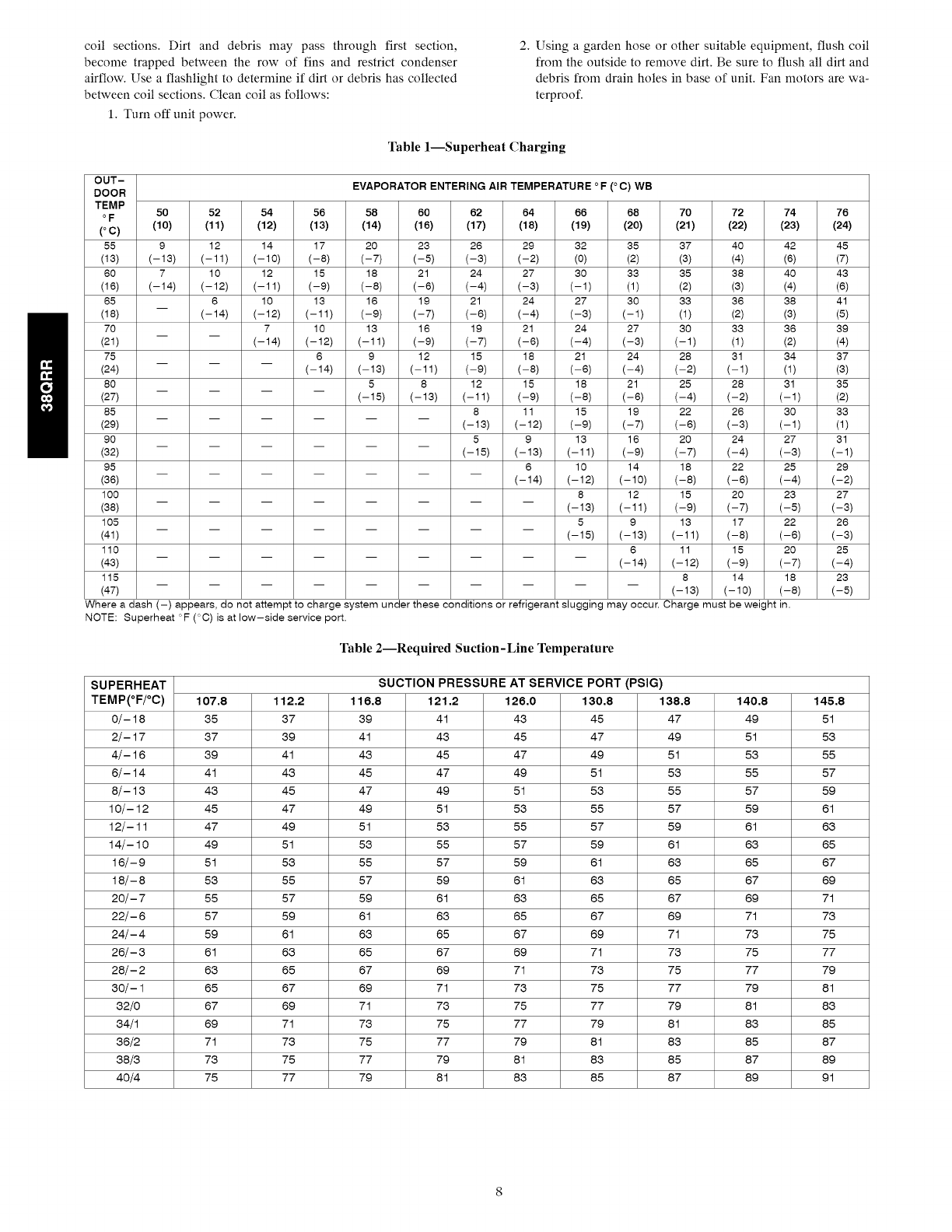

Carrier Performance 38QRR036300 User manual

Other Carrier Heat Pump manuals

Carrier

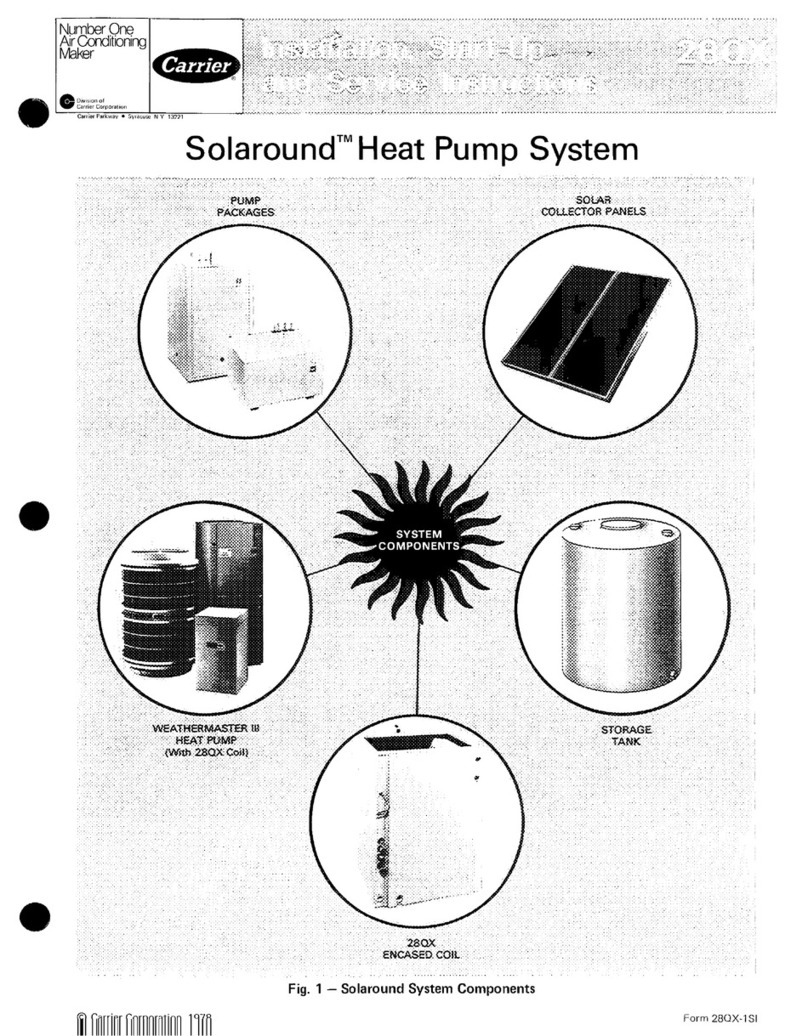

Carrier SOLAROUND 28QX Quick guide

Carrier

Carrier Bryant Evolution Extreme 186CNV User manual

Carrier

Carrier 42n User manual

Carrier

Carrier Comfort 50VT-K User manual

Carrier

Carrier 50HCQ04---12 Installation and user guide

Carrier

Carrier 39E Dimensions and installation guide

Carrier

Carrier WEATHERMASTER 50HJQ016 Dimensions and installation guide

Carrier

Carrier 50ZH Series Operation manual

Carrier

Carrier 50TFQ008-012 Dimensions and installation guide

Carrier

Carrier 38QW User manual

Carrier

Carrier AQUAZONE 50PCH Dimensions and installation guide

Carrier

Carrier GT-PX Split Series Guide

Carrier

Carrier 50JZ 024-060 Assembly Instructions

Carrier

Carrier PHD4 F Series User manual

Carrier

Carrier 30ZQ024-G Installation manual

Carrier

Carrier 50YDV Manual

Carrier

Carrier Weathermaster III 38TQ Manual

Carrier

Carrier 38YCC Series Operation manual

Carrier

Carrier WEATHERMAKER 50TFQ004 Dimensions and installation guide

Carrier

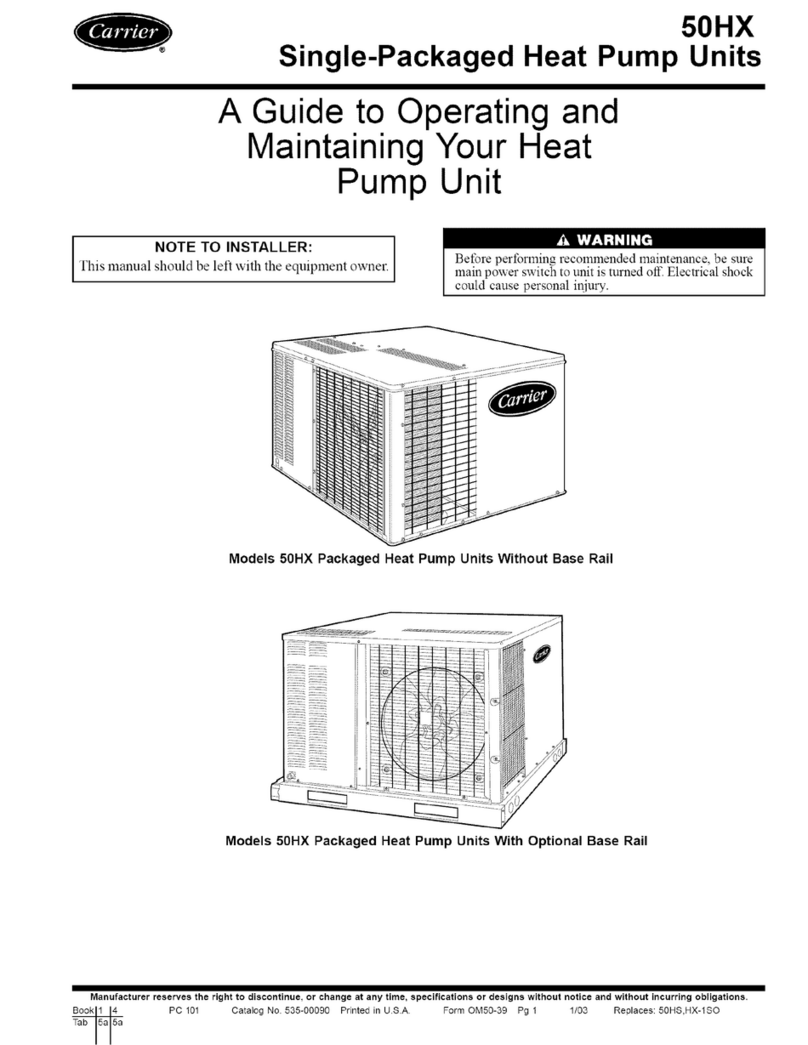

Carrier 50HX Guide User manual

Popular Heat Pump manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PUZ-SWM60VAA Service manual

Dimplex

Dimplex LI 16I-TUR Installation and operating instruction

TGM

TGM CTV14CN018A Technical manual

Kokido

Kokido K2O K880BX/EU Owner's manual & installation guide

Viessmann

Viessmann VITOCAL 300-G PRO Type BW 2150 Installation and service instructions

Viessmann

Viessmann KWT Vitocal 350-G Pro Series Installation and service instructions for contractors

Ariston

Ariston NIMBUS user manual

Weishaupt

Weishaupt WWP L 7 Installation and operating instruction

GE

GE Zoneline AZ85H09EAC datasheet

Bryant

Bryant Preferred Series installation instructions

Daikin

Daikin altherma EJHA04AAV3 installation manual

Bryant

Bryant 549B Series Installation, Start-Up and Service Instructions