40MBFAQ: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

5

SYSTEM REQUIREMENTS

Allow sufficient space for airflow and servicing unit (see Fig. 3 — on page 6 for

the minimum required distances between the unit and walls or ceilings).

Piping

IMPORTANT: Both refrigerant lines must be insulated

separately.

• Minimum refrigerant line length, between the indoor and outdoor units, is 10

ft. (3 m).

• Table 3 lists the pipe sizes for the indoor unit. Refer to the outdoor unit

installation instructions for other allowed piping lengths and refrigerant

information.

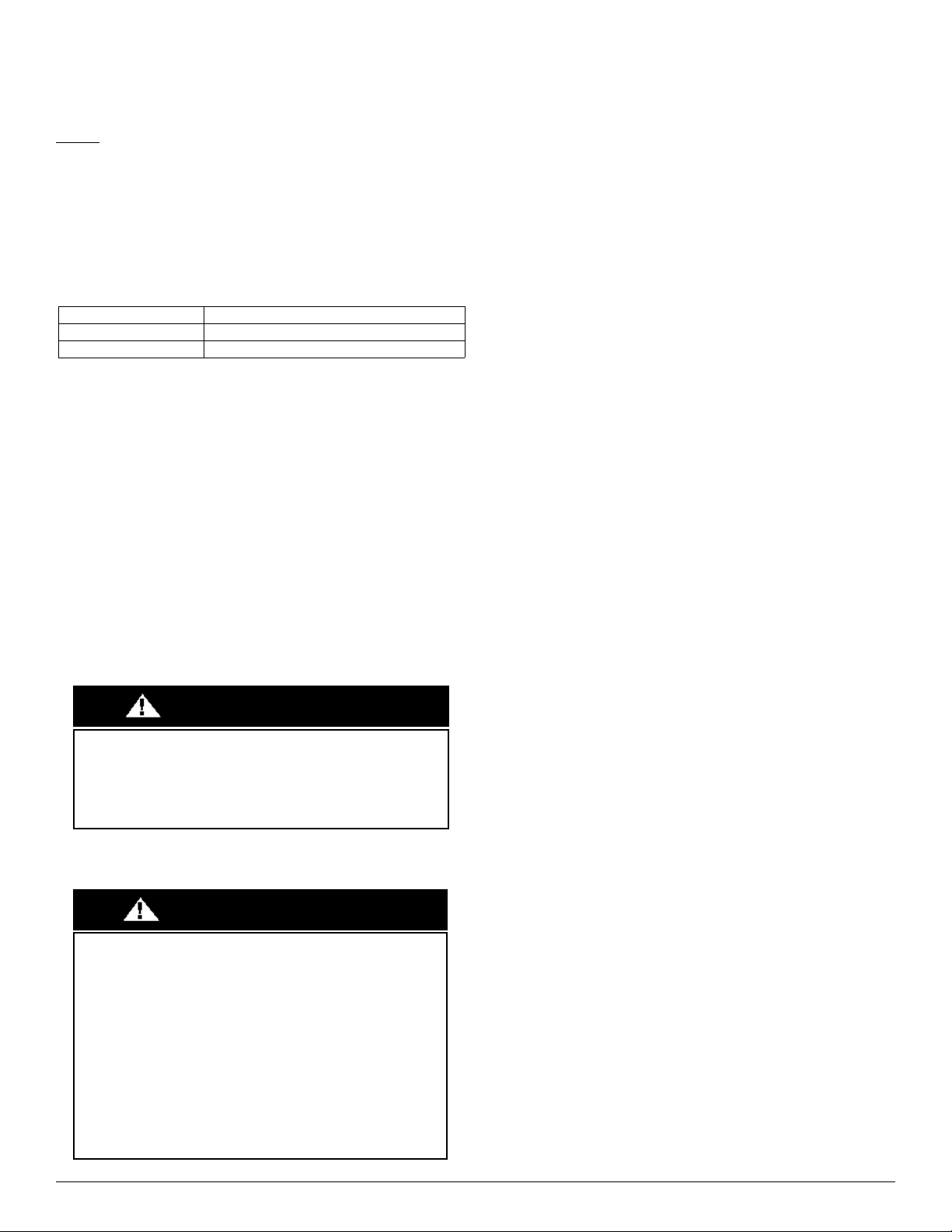

Table 3 — Indoor Unit Pipe Sizes

WIRING

All wires must be sized per NEC (National Electrical Code) or CEC (Canadian

Electrical Code) and local codes. Use Electrical Data table MCA (minimum circuit

amps) and MOCP (maximum over current protection) to correctly size the wires

and the disconnect fuse or breakers respectively.

Recommended Connection Method for Power and Communication Wiring:

The main power is supplied to the outdoor unit. The field supplied

14/3 power/communication wiring from the outdoor unit to the indoor unit consists

of four (4) wires and provides the power for the indoor unit. Two wires are high

voltage AC power, one is communication wiring and the other is a ground wire.

To minimize communication interference: If installed in a high

Electromagnetic field (EMF) area and communication issues exist, a 14/2 stranded

shielded wire can be used to replace L2 and (S) between outdoor unit and indoor

unit - landing the shield onto ground in the outdoor unit only.

NOTE: Before performing any electrical work, read these

regulations.

1. All wiring must comply with the local and national electrical codes,

regulations and must be installed by a licensed electrician.

2. All electrical connections must be made according to the Electrical

Connection Diagram located on the panels of the indoor and outdoor

units.

3. If there is a serious safety issue with the power supply, stop work

immediately. Explain your reasoning to the client, and do not install the

unit until the safety issue is properly resolved.

4. Power voltage should be within 90-110% of rated voltage. Insufficient

power supply can cause malfunction, electrical shock, or fire.

5. If connecting power to wiring, a surge protector and main power switch

should be installed.

6. If connecting power to fixed wiring, a switch or circuit breaker that

disconnects all poles and has a contact separation of at least 1/8in

(3mm) must be incorporated in the fixed wiring. The qualified

technician must use an approved circuit breaker or switch.

7. Only connect the unit to an individual branch circuit outlet. Do not

connect another appliance to that outlet.

8. Make sure to properly ground the air conditioner.

9. Every wire must be firmly connected. Loose wiring can cause the

terminal to overheat, resulting in product malfunction and possible fire.

10. Do not allow wires to touch or rest against the refrigerant tubing, the

compressor, or any moving parts within the unit.

11. To avoid getting an electric shock, never touch the electrical

components soon after the power supply has been turned off. After

turning off, the power, always wait 10 minutes or more before touching

the electrical components.

12. Make sure that you do not cross your electrical wiring with your signal

wiring. This may cause distortion and interference.

13. The unit must be connected to the main outlet.

14. No other equipment should be connected to the same power circuit.

15. Connect the outdoor wires before connecting the indoor wires.

NAME 12K

LIQUID PIPE Ø1/4” (6.35)

GAS PIPE Ø1/2” (12.7)

ELECTRICAL DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Wires should be sized based on NEC and local codes.

WA R N I N G

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Be sure to comply with local codes while running wire from the indoor

unit to the outdoor unit.

Every wire must be connected firmly. Loose wiring may cause the

terminal to overheat or result in unit malfunction. A fire hazard may also

exist. Ensure all wiring is tightly connected.

No wire should touch the refrigerant tubing, compressor or any moving

parts.

Disconnecting means must be provided and shall be located within sight

and readily accessible from the air conditioner.

CAUTION