Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500315-01 Printed in U.S.A. Form IIK-CRHEATER-07 Pg 1 9-21 Replaces: IIK-CRHEATER-04

Installation Instructions

P/N CRHEATER101A00-CRHEATER112A00, CRHEATER103B00,

CRHEATER104B00, CRHEATER113B00-CRHEATER116B00,

CRHEATER117A00-CRHEATER119A00, CRHEATER128B00,CRHEATER129B00,

CRHEATER264A00-CRHEATER269A00, CRHEATER288A00-CRHEATER297A00,

CRHEATER299A00, CRHEATER301A00, CRHEATER308A00,

CRHEATER316A00-CRHEATER321A00, CRHEATER360A00-CRHEATER364A00,

CRHEATER367A00-CRHEATER384A00,

CRSINGLE037A00-CRSINGLE054A00(STD SCCR),

CRSINGLE064A00-CRSINGLE073A00(High SCCR)

NOTE: Read these instructions completely before attempting to

install this accessory.

NOTE: HSCCR is defined as “High Short Circuit Current

Rating”. Our standard SCCR for units is 5kA, whereas HSCCR

(for Carrier units) can be 10kA to 65kA, therefor it is called

“High” SCCR or HSCCR.

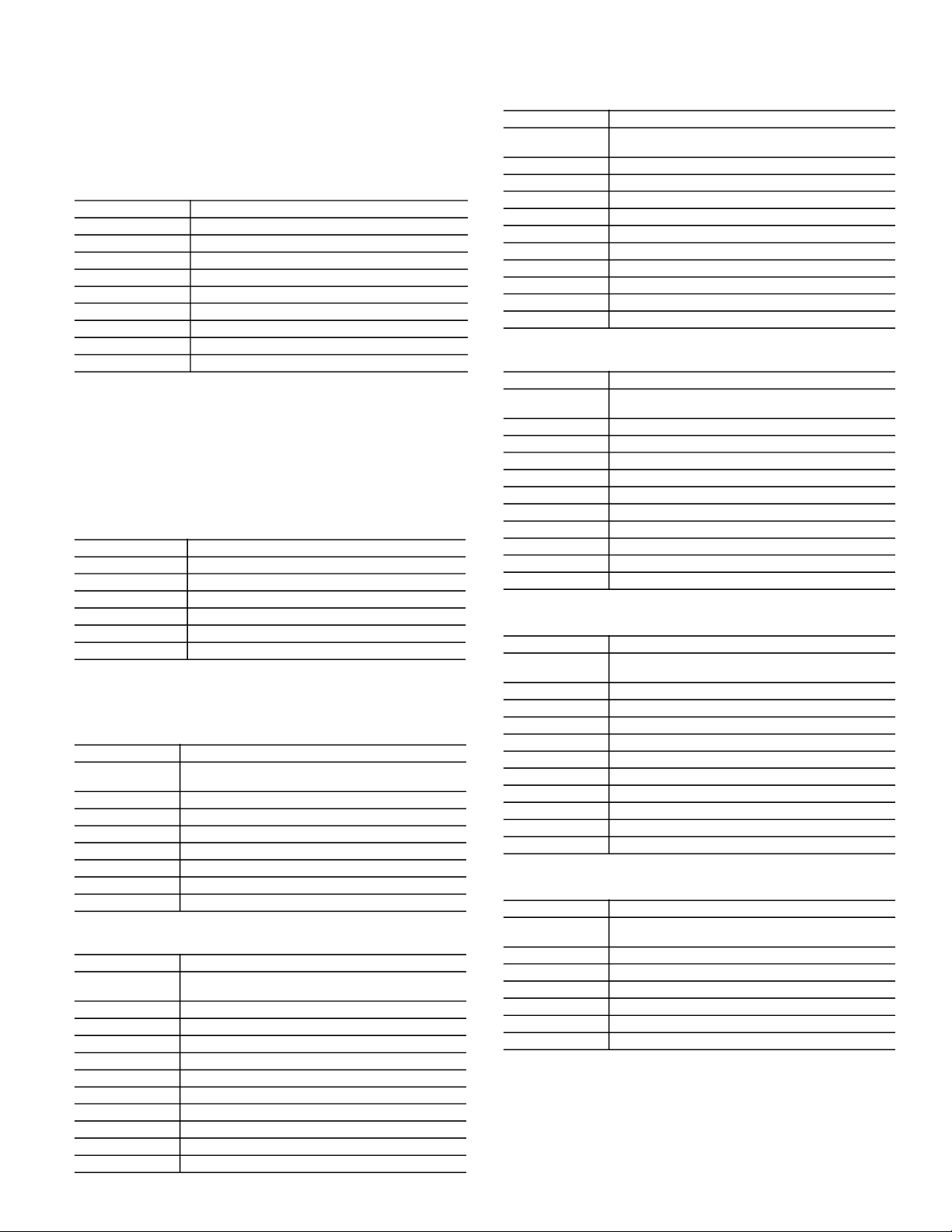

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . 1

PACKAGE CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . 3

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Puron®Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Single Point Boxes and Fuses

(STD SCCR Units) . . . . . . . . . . . . . . . . . . . . . . . . . . 6

• NON-HIGH SCCR FIOP

• NO FUSES (NON-HIGH SCCR VERSION ONLY)

• UNITS WITH FACTORY-INSTALLED HACR

(NON-HIGH SCCR VERSION ONLY)

• HIGH SCCR OPTION

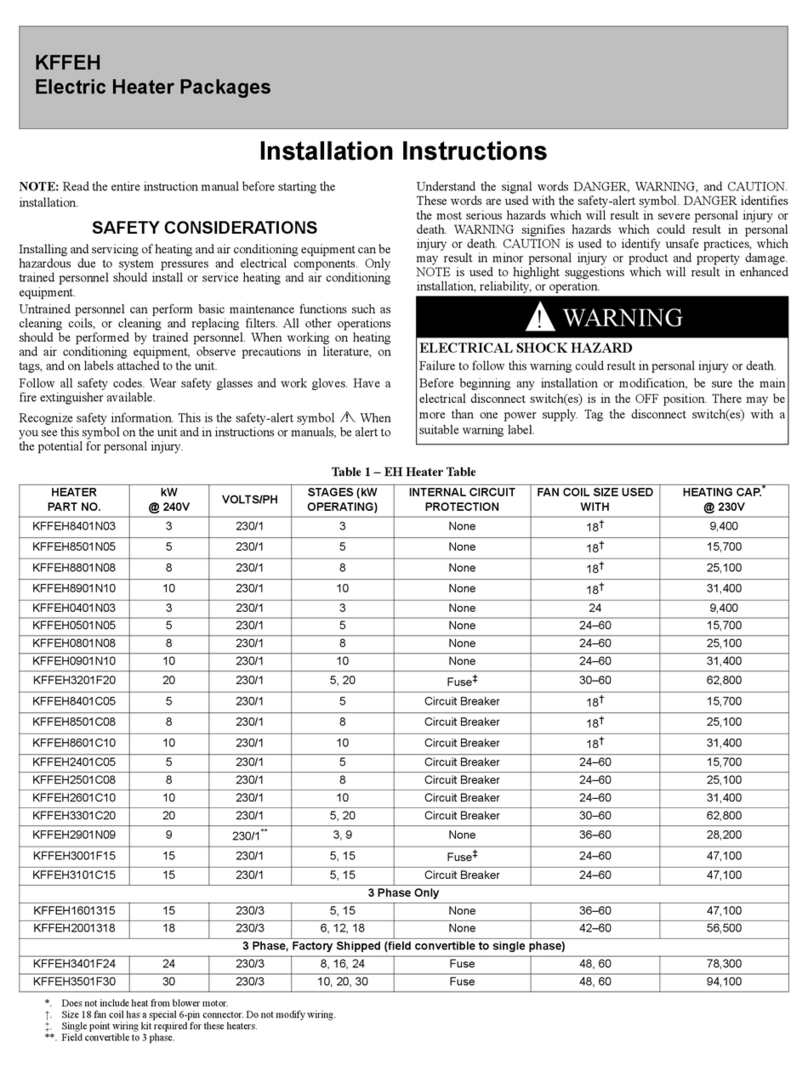

Electric Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

• SINGLE POINT BOX CONTENTS

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

• TERMINAL BLOCK TB10 (208/230-V UNITS)

(STD SCCR VERSION ONLY)

GENERAL INSTALLATION SEQUENCE . . . . . . . . . 10

UNIT-SPECIFIC INSTALLATION INSTRUCTIONS . . 11

SMALL TO MEDIUM CABINET INSTALLATION . . . 11

Check Sales Packages . . . . . . . . . . . . . . . . . . . . . . . 11

Disconnect Field Power Supply . . . . . . . . . . . . . . . . 11

• INSTALLING ELECTRIC HEATER (STD SCCR AND

HIGH SCCR UNITS)

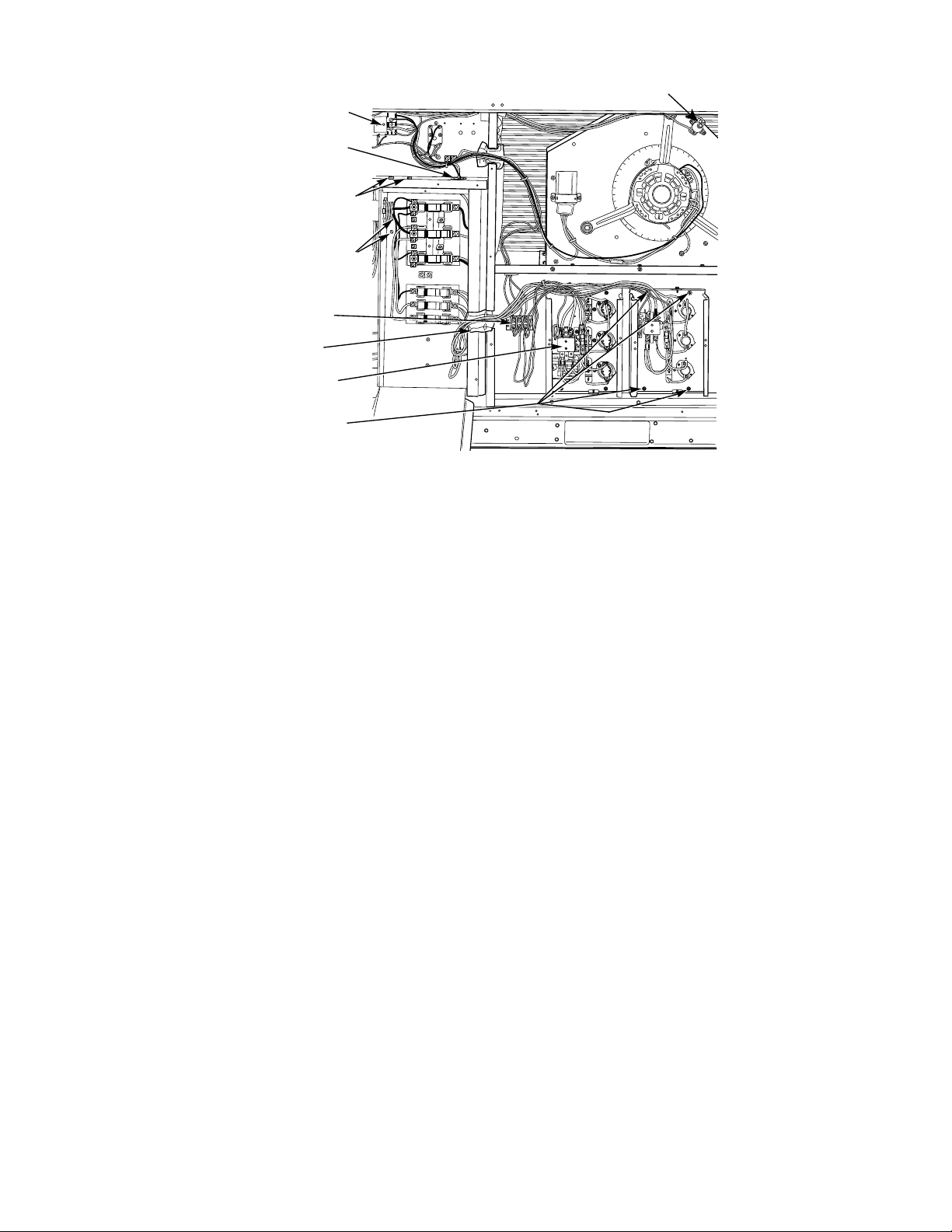

LARGE CABINET INSTALLATION . . . . . . . . . . . . . . 21

Check Sales Packages . . . . . . . . . . . . . . . . . . . . . . . 21

Disconnect Field Power Supply . . . . . . . . . . . . . . . . 21

Install Single Point Box

(CRSINGLE047A00, 049A00, 050A00-054A00 [STD

SCCR], CRSINGLE064-073A00 [High SCCR]) . . 21

Install CRHEATER288A00-296A00,

367A00-370A00, 374A00-377A00,

381A00-384A00 (STD SCCR and High SCCR) . . .24

UNIT POWER SUPPLY WIRING –ALL UNITS . . . . .31

New Unit Without Factory Disconnect or HACR . . .31

• INSTALLATION WITHOUT SINGLE POINT BOX

• INSTALLATION WITH SINGLE POINT BOX

New Unit With Factory Disconnect . . . . . . . . . . . . .32

• IF REQUIRED MINIMUM DISCONNECT VALUE IS

LOWER THAN RATING IN TABLE 14

• IF REQUIRED MINIMUM DISCONNECT VALUE IS

HIGHER THAN RATING IN TABLE 14

• FOR UNIT WITH 115-A DISCONNECT AND

REQUIRED MINIMUM DISCONNECT VALUE PER

UNIT INFO DATA PLATE IS LESS THAN 200-A

• FOR UNIT WITH 115-A DISCONNECT AND

REQUIRED MINIMUM DISCONNECT VALUE PER

UNIT INFODATA PLATE IS GREATER THAN 200-A

New Unit With Factory HACR . . . . . . . . . . . . . . . . . .32

• IF MARKED HACR VALUE ON UNIT DATAPLATE IS

UNCHANGED FROM RATING UNIT-MOUNTED

HACR

• IF MARKED HACR VALUE ON UNIT DATAPLATE IS

GREATER THAN RATING ON UNIT-MOUNTED

HACR

Existing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Complete Unit Installation . . . . . . . . . . . . . . . . . . . . .33

APPENDIX A —AC-1, AC-2 COOLING

APPLICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . .34

APPENDIX B —AC-3 50LC COOLING

APPLICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . .52

APPENDIX C —HP-1, HP-2 HEAT PUMP

APPLICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . .61

APPENDIX D —ELECTRIC HEATER DATA . . . . . . .76

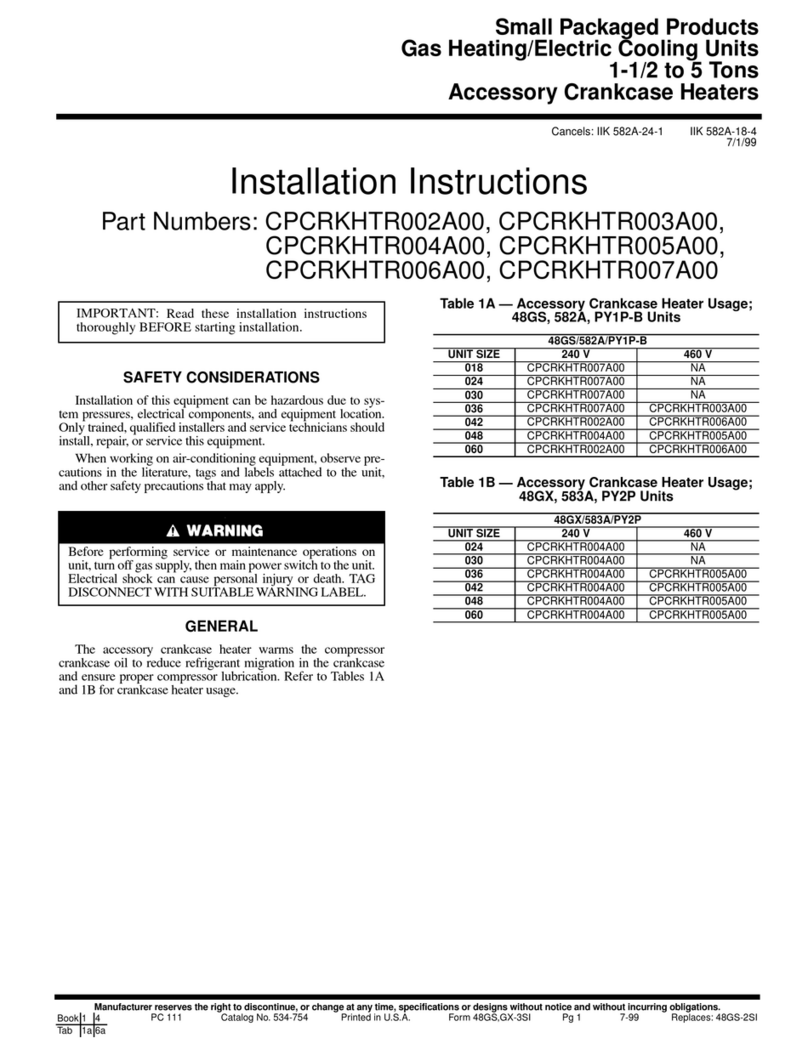

SAFETY CONSIDERATIONS

Installation of this accessory can be hazardous due to system

pressures, electrical components, and equipment location (such as

a roof or elevated structure). Only trained, qualified installers and

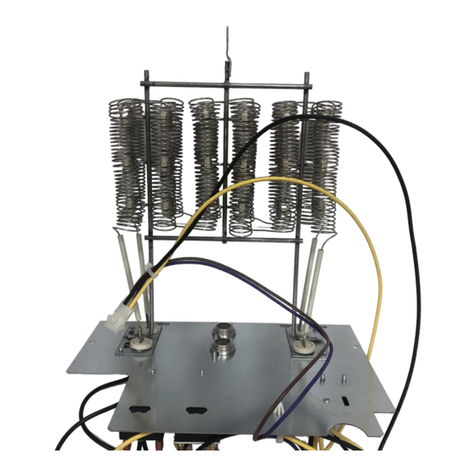

Accessory Electric Heater and Single Point Box

for Small Rooftop Units

with Electric Cooling and Heat Pump

Select 3 to 15 Ton Units